M315D2 WHEEL EXCAVATOR

The M315D2 Wheel Excavator provides fast cycle times, great lift capacity and high bucket and stick forces. This combination maximizes your productivity in any job.

SPECIFICATIONS

Engine ModelCat® C4.4

Net Power95.0 kW

Net Power (ISO 14396) at 2,000 rpm102 kW

BENEFITS AND FEATURES

engine

Engine ModelCat® C4.4

Net Power95.0 kW

Net Power (ISO 14396) at 2,000 rpm102 kW

Net Power – ISO 14396102 kW

Net Power – ISO 9249/SAE J134995 kW

EmissionsEquivalent to U.S. Environmental Protection Agency (EPA) Tier 3, EU Stage IIIA, Korea Tier 3 and China Stage II emission standards

Ratings2000.0 rpm

Bore105.0 mm

Stroke127.0 mm

Displacement4.4 L

Cylinders4

Maximum Torque at 1,400 rpm550.0 N·m

drive

Maximum Travel Speed37.0 km/h

weights

Operating Weight13 500 to 15 200 kg (29762 to 33510 lb)

VA Boom* – Rear Dozer Only14200 kg

VA Boom* – Front Dozer, Rear Outriggers15100 kg

One-Piece Boom (Standard) – Rear Dozer Only13800 kg

One-Piece Boom (Standard) – Rear Dozer, Front Outriggers14750 kg

One-Piece Reach Boom* – Rear Dozer Only13800 kg

One-Piece Reach Boom* – Front Dozer, Rear Outriggers14750 kg

Sticks – Short (2000 mm)370 kg

Sticks – Medium (2300 mm)390 kg

Counterweight – Standard2900 kg

Counterweight – Optional3300 kg

Note* Machine weight with medium stick, 3300 kg counterweight, with operator and full fuel tank, with 450 kg bucket.

Note (cont'd)Weight varies depending on configuration.

transmission

Forward/Reverse – 1st Gear9.0 km/h

Forward/Reverse – 2nd Gear37.0 km/h

Creeper Speed – 1st Gear3.0 km/h

Creeper Speed – 2nd Gear13 km/h

Drawbar Pull76 kN

Maximum Gradeability58%

swing mechanism

Swing Speed10.5 rpm

Swing Torque35 kN·m

tires

Standard10.00-20 (dual pneumatic)

service refill capacities

Fuel Tank235.0 L

Cooling31.0 L

Engine Crankcase8.0 L

Rear Axle Housing (differential)11.2 L

Front Steering Axle (differential)9.0 L

Final Drive2.4 L

Powershift Transmission2.5 L

hydraulic system

Tank Capacity95.0 L

System180.0 L

Maximum Pressure – Implement Circuit – Normal350 bar

Maximum Pressure – Implement Circuit – Heavy Lift375 bar

Maximum Pressure – Travel Circuit350 bar

Maximum Pressure – Auxiliary Circuit – High Pressure350 bar

Maximum Pressure – Auxiliary Circuit – Medium Pressure185 bar

Maximum Pressure – Swing Mechanism350 bar

Maximum Flow – Implement/Travel Circuit190 L/min

Maximum Flow – Auxiliary Circuit – High Pressure190 L/min

Maximum Flow – Auxiliary Circuit – Medium Pressure40 L/min

Maximum Flow – Swing Mechanism80 L/min

undercarriage

Ground Clearance370 mm

Maximum Steering Angle35°

Oscillation Axle Angle±9°

Minimum Turning Radius – Outside of Tire6200 mm

Minimum Turning Radius – End of VA Boom6700 mm

Minimum Turning Radius – End of One-Piece Boom8100 mm

cabfogs

StandardsCab with Falling Object Guard Structure (FOGS) meets ISO 10262.

sound levels

Exterior SoundLabeled spectator sound power level measured according to test procedures and conditions specified in 2000/14/EC is 102 dB(A).

bucket specifications

Bucket Capacities0.20 to 0.76 m3 (0.26 to 1.0 yd3)

working ranges

Maximum Reach at Ground Level8740 mm

Maximum Digging Depth5450 mm

BENEFITS AND FEATURES

M315D2 STANDARD EQUIPMENT

- electrical

Alternator, 75A

Lights: – Boom working light – Cab interior light – Roading lights two front – Roading lights two rear – Working lights, cab mounted (front and rear)

Main shut-off switch

Heavy-duty maintenance free batteries

Signal/warning horn - engine

Automatic engine speed control

Automatic starting aid

Cat C4.4 emits at levels equivalent to U.S. EPA Tier 3 and EU Stage IIIA emission standards

Fuel/water separator with level indicator - hydraulics

Heavy lift mode

Load-sensing plus hydraulic system

Anti-drift valves for boom stick and bucket

Manual work modes (economy, power)

Separate swing pump

Stick regeneration circuit - operator station

Adjustable armrests

Air conditioner, heater and defroster with automatic climate control

Ash tray with cigarette lighter (24V)

Beverage cup/can holder

Bolt-on FOGS capability

Bottle holder

Bottom mounted parallel wiping system that covers the upper and lower windshield glass

Camera mounted on counterweight displays through cab monitor

Coat hook

Floor mat, washable, with storage compartment

Fully adjustable suspension seat

Instrument panel and gauges: – Information and warning messages in local language – Gauges for fuel level, engine coolant and hydraulic oil temperature – Filters/fluids change interval – Indicators for headlights, turning signal, low fuel, engine dial setting – Clock with 10-day backup battery

Laminated front windshield: – 70/30 split, openable

Left side console, tiltable, with lock out for all controls

Literature holder in right console

Mobile phone holder

Parking brake

Positive filtered ventilation

Power supply, 12V-7A

Rear window, emergency exit

Retractable seat belt

Skylight

Sliding door windows

Steering column, tiltable

Storage area suitable for a lunch box

Sunshade for windshield and skylight

Visor for rain protection - undercarriage

Heavy-duty axles, advanced travel motor, adjustable braking force

Oscillating front axle with remote greasing

Tires, 10.00-20 16 PR, dual

Tool box in undercarriage

Second tool box for undercarriage

Two-piece drive shaft - other equipment

Automatic swing brake

Cat Product Link

Counterweight, 2900 kg

Mirrors, frame and cab

M315D2 OPTIONS

- auxiliary controls and lines

Auxiliary boom and stick lines

Anti-drift valves for tool control/multi-function circuits

Basic control circuits: – Medium pressure: Two-way, medium pressure circuit, for rotating or tilting of work tools – Hammer circuit – Tool control/multi function: One/two-way high pressure for hammer application or opening and closing of a work tool; Programmable flow and pressure for up to 10 work tools – selection via monitor; Quick coupler control

SmartBoom - front linkage

Booms: – One-piece reach boom, 4815 mm – VA boom (two piece), 5020 mm – One-piece boom, 4500 mm

Bucket linkage with diverter valve

Sticks: – 2000, 2300 mm - electrical

Back-up alarm with three selectable modes

Lights: – Rotating beacon on cab

Refueling pump - operator station

Falling object guards

Joystick steering

CD/MP3 Radio (12V) at rear location including speakers and 12V converter

Seat, adjustable high-back: – mechanical suspension – air suspension (vertical) - undercarriage

Dozer blade, rear mounted

Outriggers, rear mounted and blade front

Spacer rings for tires - other equipment

Cat Machine Security System

Counterweight, 3300 kg

Ride Control

MOTEUR

Thinking Generations Ahead

BENEFITS AND FEATURES

Fuel Efficiency and Low Exhaust Emissions The Cat C4.4 engine achieves emission levels equivalent to U.S. Environmental Protection Agency (EPA) Tier 3, EU Stage IIIA, Korean Tier 3 and China Stage 2 emission standards, while offering increased performance, high fuel efficiency and reliability. This means more work done in a day, low operating cost and minimal impact on our environment.

Quiet Operation Low sound levels, as a result of the variable fan speed and remote cooling system.

Technologies and Longer Service Intervals Product Link allows remote monitoring of the machine and helps improve your fleet efficiency as well as reduce your costs. Your Cat dealer can help extend service intervals, meaning fewer required fluids and disposals, all adding up to lower operating costs.

Fewer Leaks and Spills Lubricant filters and various drains are designed to minimize spills. Cat O-ring face seals, XT™ hoses and cylinders help prevent leaks that can reduce performance and cause harm to the environment.

Power, Reliability, and Fuel Economy

BENEFITS AND FEATURES

The Power and Performance You Need – Constant Power Strategy Responding quickly to changing loads, the constant power strategy delivers the same amount of power regardless of operating conditions. The Cat engine achieves emission levels equivalent to U.S. Environmental Protection Agency (EPA) Tier 3, EU Stage IIIA, Korean Tier 3 and China Stage 2 emission standards, delivers a maximum net power (Acc. ISO 14396) of 102 kW at a rated speed of 2,000 rpm.

Fuel Efficiency – Common Rail Fuel System and Fuel Pump This combination provides outstandingly low fuel consumption during both working and traveling applications.

Fuel Efficiency – Demand Fan Cooling System The electronically controlled hydraulic motor drives a variable speed on-demand fan, resulting in optimized fuel consumption.

Fuel Efficiency – One-Touch Low Idle Control The Automatic Engine Speed Control reduces engine speed if no operation is performed, reducing fuel consumption and sound levels.

Fuel Efficiency – Eco and Work Modes

- The Eco Mode can significantly reduce your fuel consumption

- The Travel Mode optimizes driveline performance while preserving fuel

- The Power Mode is the best compromise between productivity and fuel efficiency

Keeps Operators Productive All Shift Long

BENEFITS AND FEATURES

Comfortable Seat Options Both standard and comfort seat options give your operators all the comfort they need for a long day of work. The comfort seat is equipped with a passive seat climate control and air suspension which can be adjusted to the operator’s weight, allowing relaxed, ergonomic sitting.

Low Vibration/Sound Levels The rubber-mounted cab includes thick steel tubing. Associated with the comfortable air-suspended seat helps reduce vibrations and sound levels.

Comfortable Operation Two-way pedals for travel and auxiliary circuits provide increased floor space, reducing the need to change positions. The auxiliary high-pressure pedal can be locked in the off position and used as a footrest. The steering column is easily tiltable thanks to a large pedal at its base.

Automatic Climate Control Easy adjustment of the cab temperature with filtered ventilation to make your operators comfortable in all climates.

Storage Compartments A large compartment behind the seat provides sufficient room to store a large lunch box or a hard hat. A cover secures the contents during machine operation. Several other dedicated spaces can hold large mugs, MP3 players or a cell phone.

Power Supply and MP3 Radio The cab includes a 12V-7A power supply socket for charging electronic devices such as MP3 players, laptops and cell phones. A CD/MP3 radio is available.

For Ease of Operation

BENEFITS AND FEATURES

Ergonomic Layout and Smart Controls The operator station is designed for simplicity, functionality and ease of operation. Frequently used switches are centralized on the right-hand switch console. Features like the heavy lift mode, ride control or SmartBoom will not only increase your productivity but also help reduce fatigue for your operators.

Large Color Monitor Easy to read and in local language, you can rely on the high-resolution LCD monitor, which will keep you aware of any important information. “Quick Access” buttons allow a quick selection of favorite functions. The tool select function lets you preset up to ten different hydraulic attachments for quick tool changes.

Optimized Visibility All glass is affixed directly to the cab, eliminating the use of window frames. The 70/30 split front windshield stores the upper portion above the operator and is easy to release. A large skylight provides upward visibility and includes a retractable sunscreen. The parallel wiper system covers the entire front windshield.

Standard Rearview Camera Together with the best in class visibility to all sides, the rear view displayed on the monitor helps ensure a safe operation.

Strength and Versatility on Wheels

BENEFITS AND FEATURES

High Travel Speed (Maximum 37 km/h) Reduces travel time between sites.

Heavy-Duty Axles Rigidity and long life with effective transmission protection and heavy-duty axles. The transmission is mounted directly on the rear axle for protection and optimum ground clearance. The front axle offers wide oscillating and steering angles.

Smart Travel Alarm (Adjustable) The alarm sounds when the machine starts moving. The Auto Mode stops the alarm when it has been sounding for an uninterrupted 10-second interval. It can also be disabled (optional).

Stabilizers and Dozer Blade – Versatile Solutions to Do It All. Various undercarriage configurations are available to provide the best solution for your work environment including dozer blades and/or outriggers. Outriggers can be individually controlled to horizontally stabilize the machine even on slight slopes.

Advanced Disc Brake System Minimizes the rocking effect when working free on wheels. The disc brake system acts directly on the hub instead of the drive shaft to avoid planetary gear backlash. The axle design lowers life costs. Oil change intervals are at 2,000 working hours.

Joystick Steering Keep both hands on the joysticks even when simultaneously moving the implements and repositioning the machine, by the use of the slider switch on the right joystick.

Fast Cycle Times, Heavy Lift Capacity

BENEFITS AND FEATURES

Dedicated Swing Pump This closed hydraulic circuit maximizes swing performance without reducing power to the other hydraulic functions, resulting in smoother combined movements.

Proportional Auxiliary Hydraulics, Tremendous Versatility The versatility of the hydraulic system can be expanded to utilize a wide variety of hydraulic work tools using multiple valve options. Basic controls include (optional):

- The Multi-Combined Valve allows the operator to select up to ten preset work tools from the monitor.

- A medium pressure function providing proportional flow, ideal for tilting buckets or rotating tools

- A hammer line (one-way high pressure)

- A dedicated circuit to operate hydraulic quick couplers.

Heavy Lift Mode Maximizes your lifting performance by boosting the lifting capacity of the machine up to 7%.

Adjustable Swing Aggressiveness Allows you to adjust the aggressiveness of the machine swing to match the operator’s preferences.

Stick Regeneration Circuit Increases efficiency and helps enhance controllability for higher productivity.

Maximum Flexibility – High Productivity

BENEFITS AND FEATURES

Rugged Performance Booms and sticks are welded, box section structures with thick, multiplate fabrications in high stress areas for the tough work you do.

Flexibility The choice of various booms and sticks provides the right balance of reach and digging forces for all applications.

Sticks

- Short stick (2000 mm) for maximum breakout force and lifting capability

- Medium stick (2300 mm) for greater crowd force and lift capacity

Booms

- Variable Adjustable (VA) – improved right side visibility and roading balance. When working in tight quarters or lifting heavy loads, the VA boom offers the best flexibility.

- One-Piece Boom* and One-Piece Reach Boom – Fits best for all standard applications such as truck loading and digging. A unique straight section in the curve of the side plate reduces stress flow and helps increase boom life.

Reduces Stress and Vibration

BENEFITS AND FEATURES

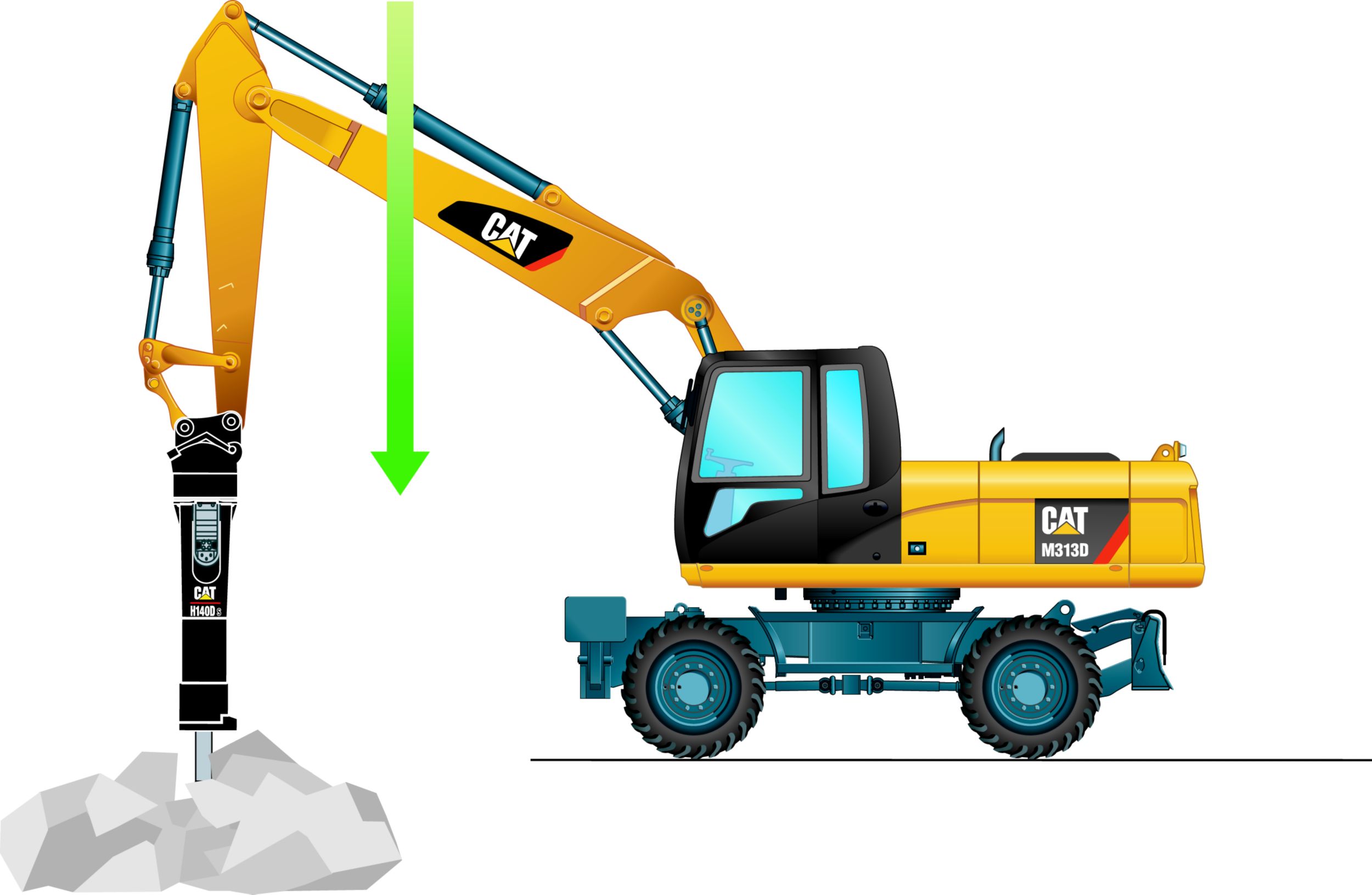

Rock Scraping Scraping rock and finishing work is easy and fast. SmartBoom simplifies the task and allows more focus on stick and bucket, while the boom freely goes up and down without using pump flow.

Hammer Work The front parts automatically follow the hammer while penetrating the rock. Blank shots or excessive force on the hammer are avoided resulting in longer life for the hammer and the machine. Similar advantages with vibratory plate compactors.

Truck Loading Loading trucks from a bench is more productive and fuel efficient as the return cycle is reduced while the boom down function does not require pump flow.

Fast Travel Speed with More Comfort

BENEFITS AND FEATURES

The ride control system lets you travel faster over rough terrain with improved ride quality for the operator. Accumulators are acting as shock absorbers to dampen the front part motion. It can be activated through a button located on the soft switch panel in the cab.

Optimizes Your Performance

BENEFITS AND FEATURES

Cat Work Tools are designed to function as an integral part of your excavator and are performance-matched to Cat machines.

Quick Couplers Hydraulic quick couplers enable to simply release one attachment and connect to another without the need to leave the cab, making your excavator highly versatile and productive. Spindle quick couplers are also available.

Buckets A wide range of specialized buckets including the Cat K Series™ or J type (depending on the region) Ground Engaging Tools is available to match all application requirements.

Hammers Cat hammer series deliver very high blow rates, increasing the productivity of your tool carriers in demolition and construction applications.

Multi-Grapples The Multi-Grapple with unlimited left and right rotation is the ideal tool for stripping, sorting, handling and loading. The powerful closing force of the grab shells combined with fast opening/closing time ensures rapid cycle time, which translates to more tons per hour.

Vibratory Plate Compactors Cat compactors integrate perfectly with the Cat hammer line – brackets and hydraulic kits are fully interchangeable between hammers and compactors.

Save Time with Every Tool Change Perform tool changes in seconds … Combine a quick coupler with common work tools that can be shared between the same size machines and you’ll get flexibility on every job. The hydraulic quick coupler automates tool exchange, so operators can change work tools quickly, from the safety and comfort of their cabs. Make your operators more efficient and productive.

Your Cat Dealer Will Support You Like No Other

BENEFITS AND FEATURES

From helping you to choose the right machine to knowledgeable on-going support, Cat dealers provide the best-in-sales and services.

- Best long-term investment with financing options and services

- Productive operation with training programs

- Preventive Maintenance and guaranteed maintenance contracts

- Uptime, with best-in-class parts availability

- Repair, rebuild, or replace? Your dealer can help evaluate the best option.

It Pays to Know

BENEFITS AND FEATURES

Product Link helps you take the guesswork out of equipment management. With timely, useful information, you can better manage your assets and costs. Just a few clicks give you access to comprehensive remote monitoring, asset tracking and maintenance management. The powerful, web-based VisionLink® application allows you to see information from all your assets – working time vs. idle time, fuel usage, diagnostic fault codes, security alerts and more. When you know where your equipment is, what it’s doing and how it’s performing, you can maximize your efficiency and lower your operating costs. It pays to know Cat Product Link. VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

When Uptime Counts

BENEFITS AND FEATURES

Extended Service Intervals to Reduce Costs

- S·O·SSM Oil Sampling Analysis – Enhances performance and durability. This system can predict potential failures and can extend hydraulic oil change intervals up to 6,000 hours.

- Engine Oil (low ash oil) – Cat engine oil is more cost effective and provides industry-leading performance. Engine oil change interval can be extended up to 500 hours.

- Capsule Filter – The hydraulic return filter prevents from contamination when the hydraulic oil is changed.

- Fuel Filters and Water Separator – The new filtration system is suited for challenging work conditions, even when using poor fuel quality. The new primary filter offers increased filtration capabilities and works in conjunction with a water separator. Fuel filters are designed to last up to 500 hours (250 hours with very poor fuel quality). The primary fuel filter includes a fuel priming pump, a water level switch and a visual restriction indicator.

- Remote Greasing – Centralized or grouped points for hard to reach locations.

- Refueling Pump (optional).

Easy Ground Level Maintenance Our excavators are designed with the operator and technician in mind. Door opening is assisted with Gaz springs.

- Front Compartment – Ground level access to the batteries, air-to-air aftercooler, air conditioner condenser and the air cleaner filter.

- Swing-out Air Conditioner Condenser allows cleaning on both sides and access to the air-to-air aftercooler.

- Engine Compartment – The longitudinal layout ensures accessibility from ground level.

Make Sure You’re Safe

BENEFITS AND FEATURES

- FOPS Certified for added protection

- Falling Objects Guards can be bolted directly on the cab (optional)

- Anti-drift Valves for booms, sticks and buckets

- Sound Proofing for a quiet operation

- Ground Level Maintenance, reducing falling hazards

- Anti-Skid Plates on top of the steps and upper structure to reduce slipping hazards

- Handrails and Steps make climbing on and off the machine easy with three points of contact

- Several Halogen Lights for proper visibility all shift long

- Rotating Beacon (optional)

- Excellent Visibility – overhead visibility is enhanced with a large skylight

- Standard Rearview Camera – clear view behind the machine through the monitor

- Implement Lock-out prevents from moving the machine unintentionally

- Smart Travel Alarm to enhance safety on your job site (optional)