KENNAMETAL

CUTTER BITS THAT FIT ALL TASKS AND CONDITIONS

JA DELMAS has been working in close partnership with KENNAMETAL, worldwide leader for tungsten carbide tools. Whatever is your business (road milling, trenching, reclaiming, stabilization, foundation drilling, surface or underground mining) KENNAMETAL cutting tools are the solution to maximize your productivity, and optimize wear resistance, regardless of the surface.

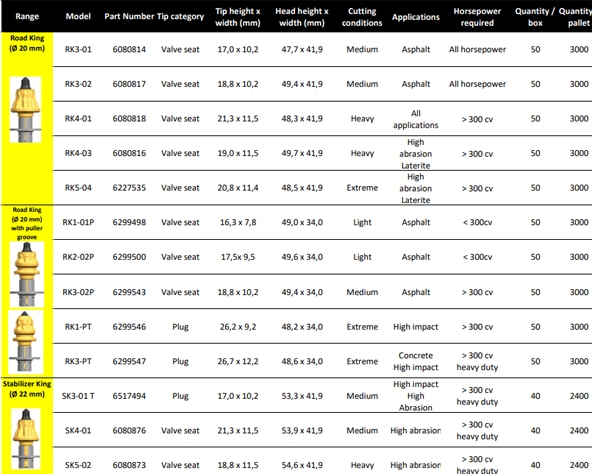

DISCOVER OUR « ROAD REHABILITATION » RANGE

Find out more on « Road King » and « Stabilizer King », our road rehabilitation and milling ranges by clicking on the below video:

What are the benefits of our « road rehabilitation » range :

5 steps to choose your cutter bit :

Step 1: Choose the shank diameter : 20, 22 mm ou 25 mm

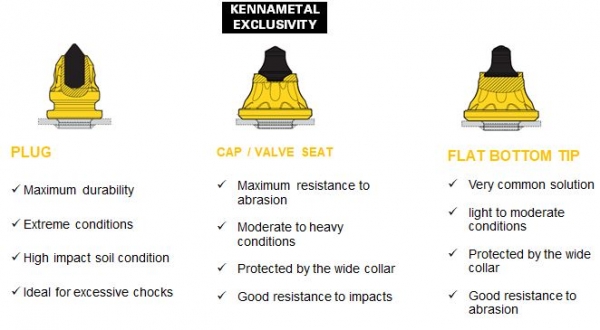

Step 2: Cutter bit profile

- Plug (heavy to extreme cutting conditions, very high impact / high abrasion)

- Valve seat (high wear resistance, good impact resistance)

- Flat bottom tip (all materials except concrete and asphalt, average resistance impact / abrasion)

Step 3: Tip dimensions

- Low diameter et high height = increased penetration, low to moderate horsepower

- high diameter et low height = increased impact, requires equipment exceeding 300 hp

Step 4: Applications

asphalt / high abrasion materials, concrete / high impact materials, soft materials etc….

Step 5: Machine horsepower (> ou < à 300 CV)

Do not forget you extraction tooling for a quicker replacement of your tips and to minimize machine downtime : please contact us.

WANT TO KNOW MORE

Download our KENNAMETAL brochures (click on the images to start downloading the document under pdf format) :

The vast majority of Kennametal parts are available on parts.cat.com, our 24/7 online ordering solution.

Any questions of our Kennametal range ? cannot find the part number you are looking for ?

- Visit www.kennametal.com

- Contact your usual Caterpillar branch

- Ask our teams to call you back on info@jadelmas.com