EL3000 LONGWALL SHEARER

The EL3000 Shearer has been developed for medium to high seams to meet the requirements of the most demanding longwall installations in the world. The EL3000 mines seams of up to 5.50 m (217 in). It offers 2 × 860 kW (2 × 1,380 hp @ 60 Hz) of cutting power combined with haulage motors of up to 2 × 150 kW (2 × 200 hp), with a 75 kW (120 hp @ 60 Hz) pump motor. With installed power of over 2000 kW (3,600 hp @ 60 Hz) it has a production capacity of more than 5000 tonnes (5,512 tons) per hour.

SPECIFICATIONS

Typical Machine Length15.2 m

Installed Power2295.0 kW

Haulage SystemAC inverter drive

BENEFITS AND FEATURES

specifications

Typical Machine Length15.2 m

Installed Power2295.0 kW

Haulage SystemAC inverter drive

mining height

Seam Range2.5-5.5 m (98-217 in)

power

Haulage Power2 × 150 kW (2 × 200 hp)

Maximum Cutting Power2 × 860 kW (2 × 1,380 hp @ 60 Hz)

Maximum Installed Power2295 kW (3,600 hp @ 60 Hz)

el3000 specifications

Machine @ 50 Hz - Available Cutting Power: RA750 Arms2 × 750 kW

Machine @ 50 Hz - Available Cutting Power: RA750 Arms2 × 620 kW

Machine @ 50 Hz - Available Cutting Power: RA860 Arms2 × 860 kW

Machine @ 50 Hz - Available Cutting Power: RA860 Arms2 × 750 kW

Machine @ 50 Hz - Body Height685 mm

Machine @ 50 Hz - Coal Sizer200 kW

Machine @ 50 Hz - Cutting Drum Diameter: RA750Up to 2500 mm

Machine @ 50 Hz - Cutting Drum Diameter: RA860Up to 2750 mm

Machine @ 50 Hz - Cutting Drum Speed: RA75032.8, 37.4 and 45.2 rpm

Machine @ 50 Hz - Cutting Drum Speed: RA86030.8, 35 and 43 rpm

Machine @ 50 Hz - Haulage Motor2 × 150 kW

Machine @ 50 Hz - Haulage PullUp to 1075 kN

Machine @ 50 Hz - Haulage SpeedUp to 31.1 m/min

Machine @ 50 Hz - Haulage SystemAC inverter drive

Machine @ 50 Hz - Installed PowerUp to 2295 kW

Machine @ 50 Hz - Machine Weight (approximate)105 tonnes

Machine @ 50 Hz - Minimum Pan Width1132 mm

Machine @ 50 Hz - Operating Voltage3,300V

Machine @ 50 Hz - Pump Motor75 kW

Machine @ 50 Hz - Seam Range2.5-5.5 m

Machine @ 50 Hz - Typical Machine Length (drum centers)15 200 mm

Machine @ 60 Hz - Available Cutting Power: RA750 Arms2 × 1,200 hp

Machine @ 60 Hz - Available Cutting Power: RA750 Arms2 × 1,000 hp

Machine @ 60 Hz - Available Cutting Power: RA860 Arms2 × 1,380 hp

Machine @ 60 Hz - Available Cutting Power: RA860 Arms2 × 1,200 hp

Machine @ 60 Hz - Body Height27 in

Machine @ 60 Hz - Coal Sizer320 hp

Machine @ 60 Hz - Cutting Drum Diameter: RA750Up to 98 in

Machine @ 60 Hz - Cutting Drum Diameter: RA860Up to 108 in

Machine @ 60 Hz - Cutting Drum Speed: RA75039.4, 44.9 and 54.3 rpm

Machine @ 60 Hz - Cutting Drum Speed: RA86037, 42 and 51.6 rpm

Machine @ 60 Hz - Haulage Motor2 × 240 hp

Machine @ 60 Hz - Haulage PullUp to 123 tons

Machine @ 60 Hz - Haulage SpeedUp to 98.7 ft/min

Machine @ 60 Hz - Haulage SystemAC inverter drive

Machine @ 60 Hz - Installed PowerUp to 3,680 hp

Machine @ 60 Hz - Machine Weight (approximate)116 tons

Machine @ 60 Hz - Minimum Pan Width44.6 in

Machine @ 60 Hz - Operating Voltage4,160V

Machine @ 60 Hz - Pump Motor120 hp

Machine @ 60 Hz - Seam Range98-217 in

Machine @ 60 Hz - Typical Machine Length (drum centers)49.9 ft

BENEFITS AND FEATURES

SERVICEABILITY

LEARN MOREEL3000 OPTIONS

- available for el3000

Multi-piece Mainframe

Cowl

Spall Guards

Coal Sizer 100 kW (134 hp)

Coal Sizer 200 kW (268 hp)

Trapping Shoe Ix (Standard)

Shearer Clearer

Spray Bars

Central Lubrication System (Standard)

PMC Evo-S (Standard)

Gate End Data Connection: - Powerline (Standard) - Fiber Optics - WLAN (Standard)

IPC

Zone-based Automation “Navigator 1”

State-based Automation “Navigator 2”

Integrated Longwall Automation with “Navigator 2 + 3” (only with Cat Longwall equipment)

“Longwall Navigator” for Improved Face Alignment and Horizon Control Incorp. LASC Tech. (only with Cat Longwall equipment)

VibraGuard

Cameras

Condition Monitoring - health monitoring

A comprehensive health monitoring system is available, including oil levels and temperatures, flows, pressures and vibration analysis. - vibraguardtm

VibraGuard allows trained personnel to predict machine component wear, avoid unplanned downtime and set alarms to warn the operator if monitored machine components run the risk of damage. This comprehensive protection backs long life and high availability of your valuable mining equipment. • Permanent online monitoring: - Replacing sporadic offline measurements, permanent online monitoring provides extensive protection and helps predict component wear. Alarms warn the operator if monitored components are at risk of damage. • Reduces unplanned downtime: - When utilized by trained personnel, VibraGuard makes repairs predictable and helps avoid unplanned downtime. This allows timely procurement of spare parts and stress-free repair. • Data analysis: - Data is transferred to a surface control center PC for detailed analysis and evaluation. - coal sizer

Cat shearers can be supplied with an optional rugged coal sizer, currently with up to 200 kW (268 hp) of installed power for maximum productivity in high seams or difficult mining conditions. The coal sizer can be ordered separately for installation during rebuild or overhaul.

Optional Machine Mounted Coal Sizer - CS200: • Transmission rating of 200 kW (320 hp @ 60 Hz) • Quillshaft transmission protection • Drum speed of 200 rpm (240 @ 60 Hz) • Drum diameter 900 mm (35.5 in) over picks • Integral water cooling for transmission and motor • Square drum hub drive for drum • Complete with anti-shock lift mechanism (unique to Caterpillar) • Available motor rating 200 kW @ 50 Hz (320 hp @ 60 Hz) - specialized shearers

Caterpillar also supplies shearers for specialized applications: • Single- and double-drum low-seam shearer • Three-drum shearer for selective mining These shearers utilize the key feature of modular mainframe construction and are proven for coal and non-coal applications.

MOTEUR

Made for Muscle

BENEFITS AND FEATURES

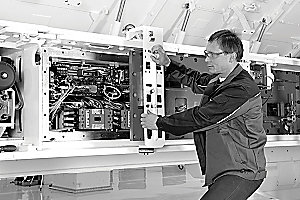

Robust One-piece Mainframe The unique mainframe of the Cat® shearer is one of its key features. The fabricated structure of the mainframe with cast ranging-arm hinge points results in an extremely robust design not only to meet the toughest mining conditions and ensure reliability and long service life, but also to handle even higher cutting and haulage forces in the future.

Retrofit-ready The mainframe of the EL3000 is designed to allow retrofit of 1200 kW (1,930 hp @ 60 Hz) ranging arms and 200 kW (268 hp) haulage units. A split mainframe is available in the event of transportation limitations.

Benefits:

- High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units.

- Maximum protection of electrical boxes, high level of flameproof integrity

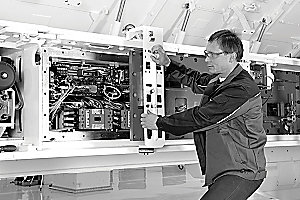

- Improved access for maintenance and ease of overhaul and repair

- Versatility of application due to fully modular construction

- Flexible and cost-effective equipment management

- Independent unit exchange and selective overhaul

- Long service life and low operational costs

Power for the Toughest Mining Conditions

BENEFITS AND FEATURES

With cutting power of 860 kW (1,380 hp @ 60 Hz), the EL3000 delivers world-class production in the toughest mining conditions.

Future-ready A new 1200 kW (1,930 hp @ 60 Hz) ranging arm is under development and can be retrofitted during rebuild.

- Cutting depth of 0.85 m (2.79 ft) and 1.0 m (3.28 ft)

- Compact design for optimum coal-loading performance

- Two-speed technology and more powerful lifting cylinder

- Modularity allows fast in-situ maintenance and repair

- Improved lubrication in lower operating temperatures

- New, more robust cowl drives

Packing More Punch

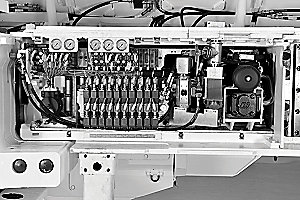

BENEFITS AND FEATURES

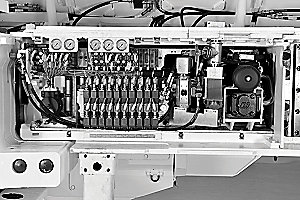

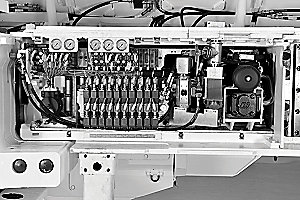

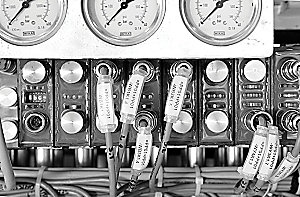

The power pack has been re-engineered to provide increased functionality, optimized performance and better access to filtration units via simplified layout.

Transformer Box • Features closed-loop control with measurement of speed, not power

Control Box • Plug and play/easy to maintain

Modular and Innovative

BENEFITS AND FEATURES

Caterpillar has further developed its modular haulage concept with increased power rating, gear rating, bearing life and redundancy, leading to longer overhaul intervals based on typical usage. The haulage system is a simple design capable of achieving cutting speeds of up to 32 m/min (105 ft/min), with improved reliability and longer service life. The haulage system offers:

- Simple construction, improved reliability and longer service life

- Fully proven load-sharing system

- Reduced cost

Modular Haulage The fully modular haulage gearbox is located in the shearer mainframe and does not form part of the shearer structure.

Separation of Structural and Wear Parts The patent-pending Trapping Shoe Ix Exchange continues the Caterpillar principle of designing products with separate structural and wear parts to allow quick and easy replacement of surfaces subject to wear.

Low Weight, Easy Replacement The new Trapping Shoe design cuts the weight that has to be handled during replacement from more than 500 kg (1,102 lb) to less than 50 kg (110 lb) per insert, and the time required for exchange to a fraction of the previous time. Because the weight is so much lower, change out can take place anywhere along the face. Previously this work had to be done at the gate ends, where heavy lifting equipment was available.

Innovative Trapping Shoe Trapping shoes attach the shearer to the haulage rack system, part of the armored face conveyor, allowing the shearer to be hauled up and down the face. The new Trapping Shoe Ix advantages:

- Greater safety and ease of handling during replacement

- Faster replacement and greater flexibility

- Longer service life and lower operating costs

Industry-leading Automation

BENEFITS AND FEATURES

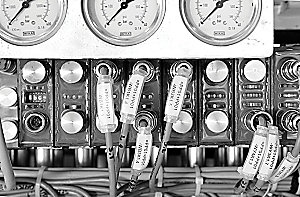

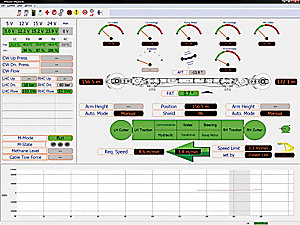

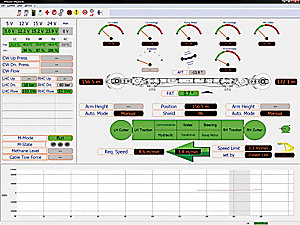

Advanced Automation Caterpillar has developed a state-of-the-art distributed automation system for the control, monitoring and protection of the shearer. Its modular design allows it to be configured to meet individual control needs, from basic monitoring and protection to advanced automation and data transmission.

Power and Flexibility With extensive computer power installed and simple upgrade to new features, Cat shearer automation is fit for the future. Components connect into the network rather than directly to a central computer, simplifying installation, wiring, maintenance, and troubleshooting.

Ethernet Bus The shearer control system uses a state-of-the-art Ethernet bus, resulting in a drastic reduction in wiring and a huge increase in flexibility. There are no interfacing problems, as equipment connected to the network only needs to be able to communicate via Internet Protocol.

Self-Configuring Commissioning, maintenance, upgrades and troubleshooting are much easier and faster, and equipment is self-configuring.

Simple Upgrade Changes to the system only require commissioning changes - such as mounting and connection of sensors. No replacement of control software is required.

Remote Control and Diagnosis Remote control and diagnosis are also possible down to I/O level.

Fault Tolerance Because of the Ethernet-based approach, the failure of one component does not impact the whole system. This allows the system to operate in the unique “fault- tolerant” mode, which allows the longwall to continue to operate when there is a problem with the overall automation system, while systematic isolation identifies faulty units while production continues.

Offers Flexibility and Power

BENEFITS AND FEATURES

Modular Control PMC Evo-S brings state-of-the art processor performance underground. Benefits include:

- Easily expandable based on modular design

- Ready for integration of highly sophisticated technologies and devices

- Equipped for XML-based interfaces to third- or fourth-party systems

Peak Performance Designed by the market leader in shearer automation, the advanced Cat automation package allows improved utilization of manpower in a safe environment; with increased yield from any given seam section, faster haulage speeds, improved face management and increased life of all longwall equipment, including AFC and shields.

Scalable Automation The degree of automation can be scaled to your needs - from basic to highly sophisticated - while remaining easy to install, operate and maintain.

Plug and Play New modules are based on standardized CIOS modules (configurable input output system), resulting in a plug and play approach to upgrades. No reprogramming is necessary.

Less Maintenance Effort Widespread use of intrinsically safe (IS) components in PMC Evo-S control system reduces time-consuming opening of flame-proof housings in the event faults. Quick and easy exchange of modules.

Making it Easy

BENEFITS AND FEATURES

PMC Evo-S offers Reliability from Day One

- Robust cables and plugs

- Minimized cabling due to network approach

- Vibration-tested components

- Designed for the working environment

Making it Easy

- Cat self-configuring controls and standard interfaces such as Ethernet allow quick and easy system configuration changes with no programming effort

- Ready for future technologies such as high-quality condition monitoring, including vibration monitoring

- Easy and flexible adaptation to existing data environments

- Greater use of Ethernet, standard connectorization and PMC control family mean greater simplicity, reduced spares inventories and shorter downtimes

- Standardization and modularization allow quick and easy customization of components and systems

Fast Troubleshooting

- Widespread use of intrinsically safe components allows large-scale fault diagnosis under power

- Remote access to most components down to I/O level

- Diagnosis from surface or by Cat Mine Control Center

- Managed switches and field bus coupler (FBC) allows selective routing:

Visualization Better Understanding of Operations - Visualization not only provides a graphical representation of current operating conditions, but can also display historical conditions and a graphic display of trends. Visualization gives operators a better understanding of the overall system, allowing them to further optimize operations. Dedicated Applications - VLongwall provides a system overview and access to the visualization modules VShield, VDrive, VPlow and VShearer. It gives access to VTrend for trend analysis and VGraph3D for waterfall plots of the entire longwall.

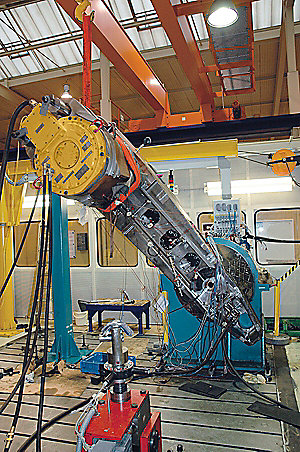

Stringent Testing to Assure Highest Quality

BENEFITS AND FEATURES

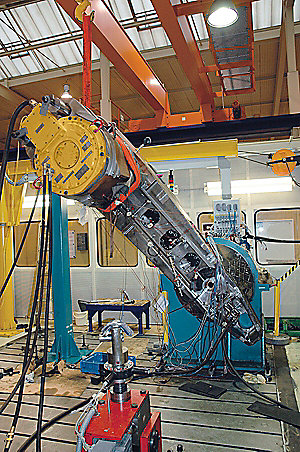

Lubrication Verification Ranging arms and haulage units are subjected to an intense test regime to establish the optimum oil-level requirements. Tests are performed with a range of different gradients and arm positions to represent even the most severe mining conditions. The units are operated until stable temperatures are achieved at all gradients to establish minimum, maximum and optimum oil quantities for all conditions.

Endurance Testing These tests apply loads far in excess of those encountered during normal mining operations, ensuring that the shearer can operate reliably at the installed power ratings. Loads of 100% to 175% ensure that the ranging arm design meets the requirements of the most demanding applications. Input torque, losses and output torque are monitored during the test, as are bearing, gear and shaft temperatures. Dedicated sensors monitor vibration. Oil samples are collected at intervals for analysis, as the presence of metal in the oil can indicate excessive component wear. Following the test, units are dismantled for a full internal and external inspection.

Production Load Testing After successful endurance block load testing, the same test rigs are used to carry out production load testing of all ranging arms and haulage units. The test gradually increases the load up to full load. All temperatures and vibration points are monitored during the test, and oil samples are again collected for analysis.

Proven Productivity This extensive range of tests ensures the highest possible availability of shearers in service and maximum return on investment for your longwall installation. Nothing is left to chance in ensuring that Cat shearers are unsurpassed in reliability.

Cat shearers: Safety is priority one

BENEFITS AND FEATURES

Product Safety Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and system designs.

Advanced Automation State-of-the-art automation reduces the number of operators required on the face.

Safe Maintenance Features to ease and make work underground safer are already considered in the design phase. Our unique trapping shoe with exchangeable inserts or the door handling system are engineered to make routine maintenance tasks easy and provide maximum safety.

Approvals and Safety Requirements Cat shearers are designed in accordance to meet the most challenging underground approvals and safety requirements all around the world.

BENEFITS AND FEATURES

Less Maintenance Effort

- Widespread use of intrinsically safe components in PMC Evo-S reduces time-consuming opening of flameproof housings in the event of faults.

- Quick and easy exchange of modules.

Extended Service Life Trapping Shoe inserts have the same wear area as conventional shoes and are articulated. This - combined with the fact that the shoe does not have to exert as much pressure, resulting in a lower point load - means less wear. Field tests of the Trapping Shoe Ix showed its service life to be 50 percent longer than conventional trapping shoes.

Downdrive An innovative downdrive design results in longer bearing life, increased gear rating and greater modularity for simplified maintenance. Height adjustment of the shearer is relatively easy and is achieved with replacement of the downdrive to allow adaption to changing seam conditions.