FACE CONVEYOR - PF5

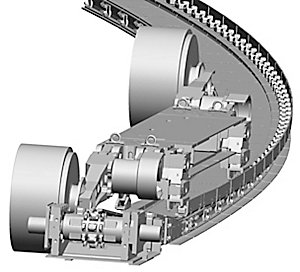

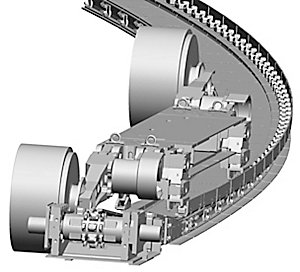

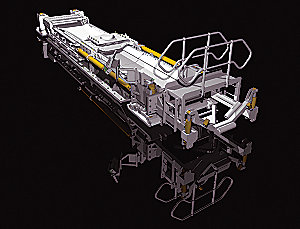

Moving Mountains - No matter how fast your shearer can cut, you can’t keep cutting until you move the coal away from the face. Cat® Armored Face Conveyors (AFCs) are designed to keep things moving and to carry the maximum possible amount of coal smoothly away from the coalface. They are designed for high availability and economy in operation. They are easy to maintain and offer long service life and a great return on investment to mine operators.

SPECIFICATIONS

Top Plate Thickness50 mm (1.96 in)

Bottom Plate Thickness30.0 mm

Dogbone Breaking Force4500.0 kN

BENEFITS AND FEATURES

engineered to perfection

There are many parts to an Armored Face Conveyor: shearer haulage system, drives, drive ...

LEARN MORE

shearer haulage system

Cat rackbar shearer haulage systems meet the demands of today’s high-performance ...

LEARN MORE

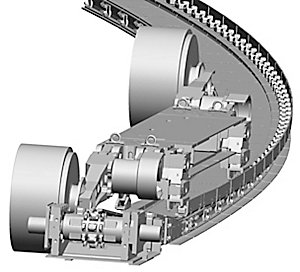

drive frames

Head-gate drive frames operated today are typical of the cross-frame design. Different ...

LEARN MOREtypical technical data afc line pan

Top Plate Thickness50 mm (1.96 in)

Bottom Plate Thickness30.0 mm

Dogbone Breaking Force4500.0 kN

technical data

Bottom Plate Thickness30.0 mm

Chain StrandsDKB 42×146; DKB 48×160/144

Conveying Capacity - PF5/11420.58 m2

Conveying Capacity - PF5/13420.85 m2

Deck Plate Thickness50.0 mm

Dogbone Breaking Strength4500 kN (505.82 tonf)

Dogbone Housing FoS1.5 times

Flightbar Width - PF5/1142988.0 mm

Flightbar Width - PF5/13421188.0 mm

Horizontal Articulation0.8°-1.2°

Line Pan Width - PF5/11421142.0 mm

Line Pan Width - PF5/13421342.0 mm

Profile Height318.0 mm

Shear Strength> 6000 kN (> 674.42 tonf)

Vertical Articulationup to ±6°

BENEFITS AND FEATURES

ENGINEERED TO PERFECTION

There are many parts to an Armored Face Conveyor: shearer haulage system, drives, drive ...

LEARN MORE

SHEARER HAULAGE SYSTEM

Cat rackbar shearer haulage systems meet the demands of today’s high-performance ...

LEARN MORE

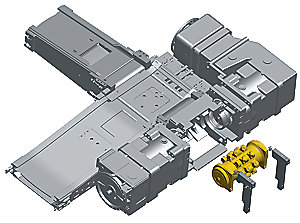

DRIVE FRAMES

Head-gate drive frames operated today are typical of the cross-frame design. Different ...

LEARN MORE

GR SPROCKET

In contrast to conventional sprockets, the Cat GR sprocket is specially designed to ...

LEARN MORE

TAIL DRIVES

Tail drives are normally the tensionable type, especially with long faces and/or high ...

LEARN MORE

GEARBOXES

Caterpillar offers gearbox solutions - simple planetary or bevel-spur gearboxes for ...

LEARN MORE

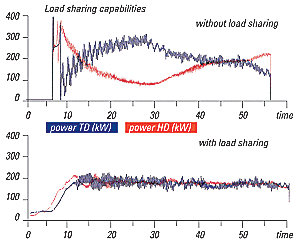

OVERLOAD PROTECTION

Overload protection is achieved by measuring the slip of each gearbox. In the event of a ...

LEARN MORE

CHAINS

For years, we have been matching chain and sprocket design in high-performance face ...

LEARN MORE

POWERCHAIN

The wide, arc-shaped cross-section of the vertical links allows a low-profile line pan ...

LEARN MORE

ENTRY CONVEYORS AND BELT ...

Entry conveyor or stageloader pans are normally of the same type as used in the face. ...

LEARN MORE

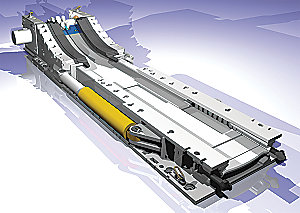

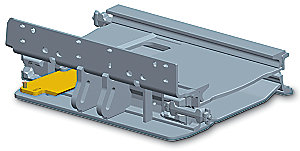

LINE PANS FOR EVERY NEED

Rolled steel is smoother, stronger and harder-wearing than a casting and generates less ...

LEARN MORE

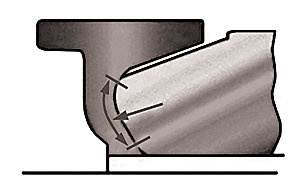

MAXIMUM CONTACT

The profiles are designed to maximize the contact area between the flight bar and the ...

LEARN MORE

ROLLED STEEL

Rolled material has a smoother surface than castings. The material shows maximum wear ...

LEARN MORE

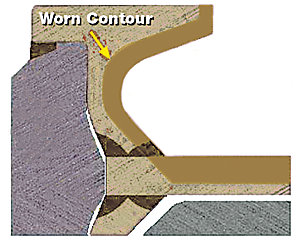

SAFE DOGBONE TECHNOLOGY

The forged dogbone pocket and the designed breaking force of up to 4500 kN guarantee safe ...

LEARN MORE

WELDS WITHOUT WEAR

Cat PF line pans have a rolled profile design. Each of the identical profiles are ...

LEARN MORE

FLEXIBILITY

The line pans are designed to allow deflection between individual line pans of ± 6° ...

LEARN MORE

INSPECTION DOORS

A sliding inspection door typically installed in every 6th pan and every special pan ...

LEARN MOREMOTEUR

There are many parts to an Armored Face Conveyor: shearer haulage system, drives, drive frames and sprockets, gearboxes, line pans, chain conveyors as well as entry conveyors and belt tailpieces. Each of these components has to be engineered to perfection, but also has to work together optimally with the other parts of the system.

BENEFITS AND FEATURES

Cat AFC components achieve this. Each is designed for powerful, reliable and economical operation with low maintenance over a long service life, promoting high productivity and delivering a great return on investment.

Cat rackbar shearer haulage systems meet the demands of today’s high-performance shearers. We use design and material selection aimed at achieving maximum system availability, longest possible shearer, sprocket and trapping shoe life and on-system suitability for seam undulations.

BENEFITS AND FEATURES

As with all Cat products, these systems are the result of extensive R

Drive Frames

BENEFITS AND FEATURES

18318830 Drive Modules

18318830 Benefits

18318832 GR Sprocket

18318834 Tail Drives

18318836 Gearboxes

18318837 Overload Protection

18318839 Chains

18318840 PowerChain

18318842 Entry Conveyors and Belt Tailpieces

18318844 Line Pans for Every Need

18318845 Maximum Contact

18318846 Rolled Steel

18318847 Safe Dogbone Technology

18318848 Convex/Concave Pan Ends

18318848

18318849 Welds without Wear

18318850 Wear-resistant Top Plate

18318850 Benefits

18318851 Flexibility

18318852 Safe Transfer of Transverse Forces

18318852 Benefits

18318853 Inspection Doors

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits

BENEFITS AND FEATURES

Benefits