AD60 UNDERGROUND ARTICULATED TRUCK

The AD60 Underground Articulated Truck is designed for high production, low cost-per-ton hauling in underground mining applications. Rugged construction and simplified maintenance guarantee long life with low operating costs. Engineered for performance, designed for comfort, built to last.

SPECIFICATIONS

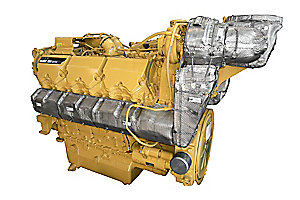

Engine ModelCat® C27 ACERT™

Gross Power - SAE J1995579.0 kW

Bore137.2 mm

BENEFITS AND FEATURES

engine

Engine ModelCat® C27 ACERT™

Gross Power - SAE J1995579.0 kW

Bore137.2 mm

Stroke152.4 mm

Displacement27.0 L

Gross Power - SAE J1995 (1st gear/2-7th gear)560/579 kW (751/776 hp)

operating specifications

Nominal Payload Capacity60000.0 kg

Gross Machine Operating Mass112000.0 kg

Body Capacities26.9-36.6 m3 (35.2-47.9 yd3)

body capacities

Dump Body - 1 (Standard)26.9 m3

Dump Body - 232.6 m3

Dump Body - 333.8 m3

Dump Body - 436.6 m3

Ejector Body - 126.9 m3

Ejector Body - 229.4 m3

weights

Empty51200.0 kg

Loaded112000.0 kg

Empty - Front Axle36096.0 kg

Empty - Rear Axle15104.0 kg

Loaded - Front Axle56000.0 kg

Loaded - Rear Axle56000.0 kg

weight distribution

Empty - Front Axle70.5%

Empty - Rear Axle29.5%

Loaded - Front Axle50.0%

Loaded - Rear Axle50.0%

body hoist

Raise12.0 Seconds

Lower24.0 Seconds

Total Cycle Time36.0 Seconds

turning dimensions

Outside Clearance Radius10005.0 mm

Articulation Angle42.5 Degrees

Frame Oscillation10°

Inside Turning Radius5540.0 mm

transmission

Forward 16.6 km/h

Forward 29.3 km/h

Forward 312.5 km/h

Forward 416.8 km/h

Forward 522.7 km/h

Forward 630.7 km/h

Forward 741.5 km/h

Reverse 18.7 km/h

service refill capacities

Engine Crankcase with Filter99.0 L

Transmission53.0 L

Hydraulic Tank258.0 L

Cooling System138.0 L

Front Differentials and Final Drives138.0 L

Rear Differentials and Final Drives138.0 L

Fuel Tank940.0 L

tires

Tire Size35 × 65 R33

standards

BrakesISO 3450-2011, AS2958.1, CAN‑CSA 424.30-M90

Cab/FOPSISO 3449-2005, SAE J231, AS2294.3, EN13627

Cab/ROPSISO 3471, SAE J1040, AS2294.2, EN13510

SteeringISO 5010-2007

final drives

Differential Ratio3.46:1

Final Drive Ratio5.5:1

Total Reduction Ratio19.04:1

BENEFITS AND FEATURES

TRUCK BODY SYSTEMS

Rugged performance and reliability in tough underground mining applications.

LEARN MORE

AD60 STANDARD EQUIPMENT

- electrical

12V Power Supply In Cab

Alternator, 95-amp

Auxiliary Start Receptacle

Battery Disconnect Switch, Ground Level

Circuit Breaker, 80-amp

Corrosive Protection Spray

Diagnostic Connector

Electric Starting, 24-volt

Engine Shutdown Switch, Ground Level: – Front Left Hand Side

Lighting: – Brake and Tail Light, LED – Headlights with Dimmer Switch, Halogen – Rear Work Light (Cab Mounted), Halogen – Reversing Lights, Halogen

Low Maintenance Batteries

Reversing Alarm

Starting and Charging System - operator environment

Cat Electronic Monitoring System (Cat EMS)

Electric Horns

Gauges: – Engine Coolant Temperature – Transmission Coolant Temperature – Hydraulic Oil Temperature – Fuel Level – Speedometer – Tachometer

Indicator Lights: – Alert Warning Light – Body Up Position Warning – Brake Drag Indicator – High Beam – Residual Brake Pressure Warning – Retarder Application – Turn Signal

Low Hydraulic Level Warning

Operators Station ROPS/FOPS Enclosed: – Air Conditioning and Heater – Cab Pressurizer and Filter – Dome Light – Radio Ready Compartment for Radio and Speakers – Storage Compartment – Window, Sliding Cab Door – Windshield Wiper and Washer

Operator Presence System (Auto Park Brake)

Rearview Mirrors

Suspension Seat Cat Comfort TLV2 Air with Retractable Seat Belt

Trainer/Passenger Seat and Seat Belt

Tilt/Telescopic Steering Wheel

Turn Signal Indicators - power train

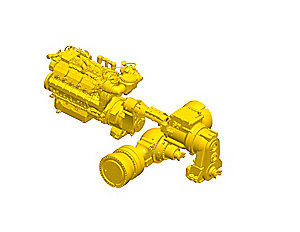

Cat C27 ATAAC Diesel Engine, 12 Cylinder

Automatic Brake Retarder Control

Auto Shift Transmission 7 Speed Forward/ 1 Speed Reverse

Control Throttle Shifting

Engine Air Intake Precleaner

Electric Fuel Priming Pump

Exhaust, Turbo Compartment Shielding

Four Wheel Drive

Long Life Coolant

Programmable Ground Speed Limiting

Programmable Gear Blockout with Tray Up

Radiator Cap Manual Release

Radiator, Cross Flow

Remote Transmission Hydraulic Oil Cooler

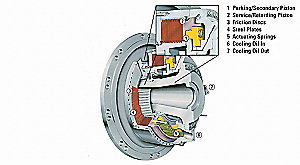

SAFR™ Full Hydraulic Enclosed Wet, Multiple-Disc Brakes, Oil Cooled

Torque Converter, Standard with Automatic Lockup - other standard equipment

Body, Dump (26.9 m3/35.2 yd3)

Catalytic Exhaust Purifier/Muffler Group

Centralized Lubrication Points

Decals, International Picto Graphics

Dual Fuel Tanks

Engine and Transmission Belly Guards

Fenders, Front, Rear Flaps

Fire Wall

Front Axle Suspension

Frame Lifting Lugs

Front and Rear Tow Pin

Front Rubber Bumpers

Fuel System Manual Shut Off Tap

Hand Hold (Access On/Off Top Deck)

Hitch, Articulated and Oscillated

Operator and Maintenance Manual, English

Secondary Steering System

S·O·S port: – Coolant – Engine Oil – Hydraulic Oil – Transmission Oil

Swing Out Radiator Grill

TPMS (Truck Payload Measurement System), Dump Body Only

Technology: – Vital Information Management System (VIMS) Gen 3

Ventilated Hood and Covers

Tires and Rims: A tire must be selected from the mandatory attachments section of the machine price list. Base machine price includes a standard tubeless rim allowance only.

AD60 OPTIONS

- battery shutdown

Ground Level Isolation, In Cab Isolation Switch

Ground Level Isolation, Engine Shutdown Switch

Ground Level Isolation, In Cab Isolation, Engine Shutdown Switch - body dump

Body, (32.6 m3/42.6 yd3)

Body, (33.8 m3/44.2 yd3)

Body, (36.6 m3/47.9 yd3) - body ejector

Ejector, (26.9 m3/35.2 yd3)

Ejector, (29.4 m3/38.5 yd3) - body liners impact andor wear

10 mm, Body, Dump (26.9 m3/35.2 yd3)

10 mm, Body, Dump (32.6 m3/42.6 yd3)

10 mm, Body, Dump (33.8 m3/44.2 yd3)

10 mm, Body, Dump (36.6 m3/47.9 yd3) - body wear plate external

8 mm, Body, Dump (26.9 m3/35.2 yd3)

8 mm, Body, Dump (32.6 m3/42.6 yd3)

8 mm, Body, Dump (33.8 m3/44.2 yd3)

8 mm, Body, Dump (36.6 m3/47.9 yd3) - brake pressure gauges

- camera color rear facing

- cover anti vandalism for shipping

- engine options

Diesel Particulate Filter - fast fill system

Coolant

Engine Oil

Fuel (Dual Tanks)

Hydraulic Oil

Transmission Oil - fire suppression system

Ansul, Dry Powder

Foam, Water Based - fluids

Arctic Fuel

Arctic Coolant - lighting

Headlights with Dimmer Switch, LED

Rear Work Light (Cab Mounted), LED

Reversing Lights, LED - lubrication system

Automatic, Dump or Ejector Body - operator station

Air Conditioner Diverter Duct

Sun Visor - operator and maintenance manual

Chinese

Indonesian

French

Portuguese

Russian

Spanish - park brake switch engagement

Push to Apply

Pull to Apply - payload

Remote Display for TPMS - reflective tape

- rims

Rim Identification Numbering

Spare, Tubeless - seat cover

Tee and Cat Comfort TLV2

Seat Cover, Companion - secondary steering system

- service tools

Collet Jacking Bolts, Dump or Ejector

Diagnostics Box

Hoist Cylinder Supports (for Body Removal)

Brake Wear Gauge

Reference Parts Manual for Additional Tooling Available - switches

Idle Timer - tire arrangements

Tire, 35/65 R33 VSNT Bridgestone

Tire, 35/65 R33 VSDL Bridgestone - note not all features are available in all regions

- see your cat dealer for more information

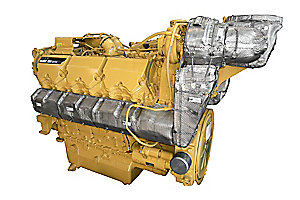

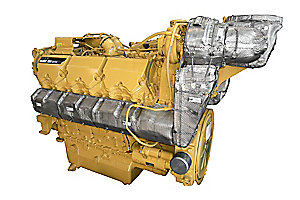

MOTEUR

The Cat C27 engine is built for power, reliability and efficiency.

BENEFITS AND FEATURES

ACERT Technology The Cat C27 achieves emissions equivalent to U.S. EPA Tier 2 and EU Stage ll standards. It delivers higher power and greater durability for maximum hauling performance in the most demanding mining applications. Complete system integration of the engine and transmission optimizes performance and efficiency.

Power Increase The 21.8% power increase over previous models provides unequalled lugging force during acceleration and less down-shifting on grade. Improved software and updates in engine technology further improve transmission shifting and decrease fuel consumption.

Watercooled Turbocharged and ATAAC Air-to-air aftercooling provides improved fuel economy by packing cooler, denser air into cylinders for more complete combustion of fuel and lower emissions.

Electronic Unit Injection (EUI) The electronically controlled unit injection fuel system senses operating conditions and regulates fuel delivery for optimum fuel efficiency. The proven high-pressure fuel system provides improved response times and more efficient fuel burn with lower emissions and less smoke.

Electronic Control Module (ECM) ECM utilizes advanced engine management software to monitor, control and protect the engine utilizing self-diagnosing electronic sensors. The computerized system senses operating conditions and power requirements and adjusts engine for peak performance and most efficient operation at all times.

Design Caterpillar designed one-piece cast iron block provides maximum strength and durability. Two-piece articulated pistons with forged steel crowns are designed to withstand higher cylinder pressure.

More power to the ground for greater productivity.

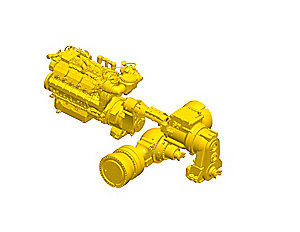

BENEFITS AND FEATURES

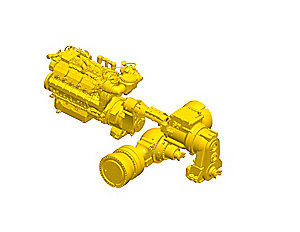

Mechanical Power Train The Cat mechanical drive power train and power shift transmission provide unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads and drives with high rolling resistance.

Transmission The Cat seven-speed planetary power shift transmission is matched with the direct-injection C27 engine with ACERT Technology to deliver constant power over a wide range of operating speeds. Individual clutch modulation provides smooth clutch engagements to optimize performance and extend clutch life.

Lock-Up Torque Converter Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. When engaged, lock-up provides superior power train efficiency by delivering more power to the wheels.

Lock-Up Clutch Quickly releases and re-engages to reduce power train torque loads for smoother shifting, long life and a more comfortable ride.

Remote Transmission Oil Cooler Increases cooling capacity in the transmission oil circuit to ensure optimal performance on long, uphill loaded hauls.

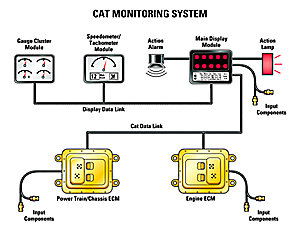

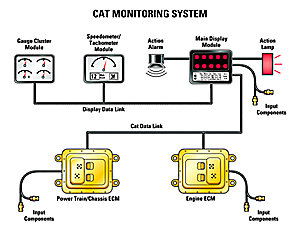

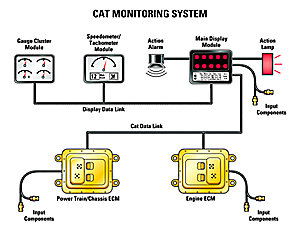

Intelligent electronics for overall optimal performance.

BENEFITS AND FEATURES

Cat Data Link Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs.

- Controlled Throttle Shifting - Regulates engine RPM, torque converter lock-up and transmission clutch engagement for smoother shifts and longer component life.

- Economy Shift Mode - Decreases fuel consumption, lowers noise levels and potentially longer engine life.

- Directional Shift Management - Regulates engine speed to prevent damage caused by high speed directional changes.

- Body-up Shift Inhibitor - Prevents the transmission from shifting above a pre-programmed gear without the body fully lowered.

Electronic Technician (Cat ET) Cat ET service tool provides service technicians with easy access to stored diagnostic data through Cat Data Link to simplify problem diagnosis and increase availability.

Overspeed Protection The Automatic Retarder Control (ARC) system provides engine overspeed protection. The ARC will engage the brakes if the following conditions exist at the same time:

- An unsafe engine speed is reached.

- The ARC on/off switch is in the ON position or the OFF position.

- The throttle is being depressed by the operator. If the transmission is in top gear, the lockup clutch is deactivated in order to protect the engine against an engine overspeed condition.

Superior control for operator confidence.

BENEFITS AND FEATURES

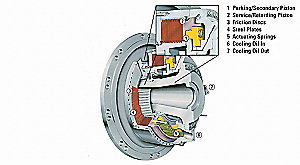

Integrated Braking System The Cat oil-cooled braking system delivers reliable performance and control in the most extreme underground mining conditions. The integrated system combines the service, secondary, parking brake and retarding functions in the same robust system for optimum braking efficiency.

Oil-Cooled Multiple Disc Brakes Four-wheel, forced oil-cooled, multiple disc service brakes are continuously cooled by a water-to-oil heat exchangers for non-fade braking and retarding performance. They are also completely enclosed to prevent contamination and reduce maintenance.

Automatic Retarder Control (ARC) Electronically controls retarding on grade to maintain optimum engine RPM and oil cooling. Additional braking may be applied using the manual retarder or the brake pedal. ARC also allows the operator to maintain optimum engine speeds for faster downhill hauls and greater productivity. The ARC automatically activates when engine speed exceeds factory preset levels.

Superior Control Automatic brake modulation offers a smoother ride and greater control, allowing the operator to concentrate on driving.

Ergonomically designed for all-day comfort, control and productivity.

BENEFITS AND FEATURES

The AD60 operator station is ergonomically designed for total machine control in a comfortable, productive and safe environment. All controls, levers, switches and gauges are positioned to maximize productivity and minimize operator fatigue.

Protective Structure Integral to the cab and frame, both the Rollover Protective Structure (ROPS) and Falling Objects Protective Structure (FOPS) are resiliently mounted to the mainframe to isolate the operator from vibration for a more comfortable ride.

Standard Enclosed Cab Standard sound-suppressed ROPS cab provides a quiet, secure and comfortable air-conditioned working environment with fresh, pressurized, temperature-controlled air circulation.

Cat Comfort Air Suspension Seat Ergonomic, fully adjustable suspension seat provides optimal operator comfort. Designed to minimize vertical and lateral motion of the operator. Thick cushions reduce pressure on lower back and thighs. Wide, retractable seat belts provide a secure, comfortable restraint.

Steering Column Comfort wheel with tilt steering provides a comfortable driving position, secure grip and greater control.

Monitoring System Cat Electronic Monitoring System (Cat EMS) continuously provides critical machine data to keep the machine performing at top production levels. Displays are backlit for easy viewing.

Rugged performance and reliability in tough underground mining applications.

BENEFITS AND FEATURES

Body Design Cat truck bodies are designed for optimal strength, capacity, durability and low cost per ton.

Cat Truck Bodies Caterpillar has two body styles to meet your application:

- Dump Body

- Ejector Body

Body Selection Selection of the right body depends on material, haul road, and dump conditions. The better the match of body to application, the greater the efficiency. Its diverging flow design gives clean load ejection, which maximizes production and avoids material carryback.

Body/Chassis Integration Cat truck bodies are designed and matched with the integrated chassis system for optimum structural reliability, durability and long life.

Fast Hoist Cycle Times Single-stage hoist cylinders provide fast dump cycle times of 12 seconds for raise and 24 seconds for lower.

Truck Payload Management System (TPMS) The standard TPMS system calculates the payload the truck is carrying and determines truck cycle times.

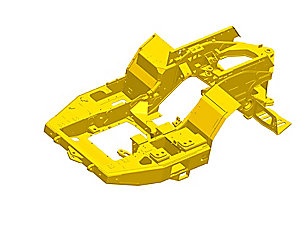

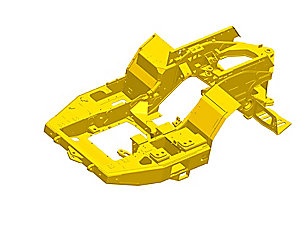

Rugged Cat structures - the backbone of the AD60’s durability.

BENEFITS AND FEATURES

Frame Design The frame uses box-section design with stiff frame beams to resist twisting forces giving it a longer structural life.

Articulating/Oscillating Hitch This system provides steering and oscillation and enables the truck to maintain all wheel ground contact in rough terrain.

More time for production.

BENEFITS AND FEATURES

Ground-Level Service Access Easy access to daily service points allows convenient servicing to tanks, filters, lubrication points, compartment drains and sight gauges for quick fluid level checks. Electric fuel priming capability and remote mounted fuel filters to save time during maintenance operations.

Diagnostics - Cat Electronic Technician Electronic control system enables quick diagnosis of engine conditions and effective maintenance and repairs utilizing the Cat ET Service Tool.

Scheduled Oil Sampling S·O·SSM helps avoid minor repairs becoming major ones. Sample point adaptors fitted standard to machine.

Sight Gauges Makes fluid level checks quick and easy. These include the hydraulic, transmission and coolant reservoirs.

Cat dealer services keep underground mining equipment productive.

BENEFITS AND FEATURES

Dealer Capability Cat dealers will provide the level of support you need, on a global scale. Dealer expert technicians have the knowledge, experience, training and tooling to handle your repair and maintenance needs. They offer 24/7 product support via a worldwide network of reliable and prompt parts distribution facilities, dealer service centers, and technical training facilities to keep your equipment up and running.

Service Support Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Cat dealers offer a wide range of service plans that will maximize return on your investment, including:

- Preventive Maintenance Programs

- Diagnostic Programs, such as Scheduled Oil Sampling and Technical Analysis

- Rebuild and Reman Options

- Customer Support Agreements

Technology Products Cat dealers offer a range of advanced technology products designed to improve efficiency, productivity and lower costs. The standard VIMS™ Gen 3 system enables your equipment to provide detailed data about its own health and working conditions by monitoring key temperatures, pressures, and more.

Operator Training Your Cat dealer can arrange operator training to improve productivity, decrease downtime, reduce operating costs and enhance safety.

Designed with safety as the first priority.

BENEFITS AND FEATURES

Product Safety Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and systems designs.

Engine Shutoff Switch A secondary engine shutoff switch is located at ground level.

Integral ROPS Cab Integral to the cab and frame, the ROPS is resiliently mounted to the frame to isolate the operator from vibration for a more comfortable ride.

Brake Systems Four corner oil-cooled braking system provides excellent control. The service brakes and retarding system are actuated by modulated hydraulic pressure, while the parking brake function is spring applied and hydraulic released. This system assures braking in the event of loss of hydraulic pressure.

Operator Present System The Operator Present System helps to protect the machine and operator from uncontrolled movements. The system automatically engages the parking brake, neutralizes the steering, implement and transmission control, and shuts down the engine in the event operator fails to apply the park brake prior to exiting the cab. The engine shutdown configuration can be changed by your Cat dealer using the Cat ET service tool.

Standard Safety Features Anti-skid upper deck surfaces, upper deck handrails, 3-point cabin and machine access, push out safety glass, excellent visibility, suspension seat, passenger/training seat, inertia reel retractable belts, steering frame lock, rear window guard, body retaining pins, automatic retarder control, exhaust heat shielding and firewall fitted standard, hitch hydraulic hoses - burst protection sleeves fitted, tailgate retaining pins (ejector body), alternate exit via windows, ground level compartment sight glasses, hot and cold side of engine.

SAFETY.CAT.COM™ For more complete information on safety, please visit http://safety.cat.com.