572R2 PIPELAYER

Cat Pipelayers have been the standard of the pipeline industry for decades. A worldwide network of Cat dealers, in tune with the special high production needs of pipeliners, supports these durable and dependable machines. Cat Pipelayers are purpose-built to meet the unique demands of pipeline customers. And like every Cat machine, pipelayers are designed for long life, serviceability and rebuild capability to help keep owning and operating costs low.

SPECIFICATIONS

Engine ModelCat® 3176C

Flywheel Power179.0 kW

Gross Power192.0 kW

BENEFITS AND FEATURES

engine

Engine ModelCat® 3176C

Flywheel Power179.0 kW

Gross Power192.0 kW

Net Power – EEC 80/1269179.0 kW

Net Power – SAE J1349177.0 kW

Bore125.0 mm

Stroke140.0 mm

Displacement10.3 L

Gross Power (Metric)192.0 kW

Gross Power – ISO 14396 (Metric)189.0 kW

Gross Power – ISO 14396189.0 kW

Net Power – EEC 80/1269 (Metric)179.0 kW

Net Power – ISO 9249179.0 kW

Net Power – ISO 9249 (Metric)179.0 kW

Net Power – SAE J1349 (Metric)177.0 kW

Rated Flywheel Power179.0 kW

Rated Flywheel Power (Metric)179.0 kW

pipelaying equipment

Lift Capacity40800.0 kg

Boom Length6.1 m

Hook Winch Drum Diameter254.0 mm

Rope Minimum Breaking Strength261.66 kN

Boom Winch Drum Diameter224.0 mm

Hook Winch Flange Diameter457.0 mm

Boom Winch Flange Diameter406.0 mm

Hook Winch Drum Length279.0 mm

Boom Winch Drum Length254.0 mm

Diameter – Wire Rope19.0 mm

Hook Winch Capacity – 19 mm (3/4 in) Diameter80.16 m

Boom Winch Capacity – 19 mm (3/4 in) Diameter51.82 m

Hook w/Wire Rope Installed – 19 mm (3/4 in) Diameter50.29 m

Boom w/Wire Rope Installed – 19 mm (3/4 in) Diameter40.23 m

Boom Line Speed73.0 m/min

4 Part Line Hook Speed (Lo)11.0 m/min

4 Part Line Hook Speed (Hi)22.0 m/min

Lift Capacity at Tipping Point40800.0 kg

Removable Counterweights – 4 Segments: 1 at1438.0 kg

Removable Counterweights – 4 Segments: 1 at1918.0 kg

Removable Counterweights – 4 Segments: 2 at370.0 kg

Removable Counterweights – Number of Segments4

Removable Counterweights – Total 4 Segments4096.0 kg

Total Weight Extendible5080.0 kg

weights

Shipping Weight31347.0 kg

Operating Weight32342.0 kg

transmission

1 Forward3.52 km/h

2 Forward6.1 km/h

3 Forward10.54 km/h

1 Reverse4.54 km/h

2 Reverse7.85 km/h

3 Reverse13.58 km/h

undercarriage

Track Gauge2235.0 mm

Track on Ground3176.0 mm

Ground Contact Area4.19 m2

Ground Pressure74.46 kPa

Number of Shoes (each side)43

Track Rollers (each side)7

Track Shoe Width660.0 mm

service capacities

Fuel Tank479.0 L

Crankcase (with Filter)31.0 L

Transmission, Bevel Gear, and Steering Clutch183.0 L

Final Drives (each)13.0 L

Cooling System77.4 L

Hydraulic Tank54.1 L

Recoil Spring Compartments (each)57.0 L

dimensions

Track Gauge2235.0 mm

Width of Tractor – Boom Removed3659.0 mm

Width of Tractor – Counterweight Extended5228.0 mm

Machine Height – Tip of Grouser to Top of Winch2895.0 mm

Drawbar Height (Center of Clevis)634.0 mm

Length of Track on Ground3176.0 mm

Operating Length (with Drawbar)4736.0 mm

Height to Top of Stack3387.0 mm

Grouser Height71.0 mm

Ground Clearance (SAE J1234)416.0 mm

Boom Height – Tip of Grouser at SAE 1.22 m (4 ft) Overhang6728.0 mm

Machine Height – Tip of Grouser to Top of ROPS3450.0 mm

Width of Tractor2895.0 mm

hydraulic controls

TypePressure compensating piston-type pump.

Output – Maximum281.0 L/min

Relief Valve Setting – Counterweight17240.0 kPa

Relief Valve Setting – Hook and Boom Winch33000.0 kPa

standards

BrakesBrakes meet the standard SAE J/ISO 10265:2008.

ROPSROPS offered by Caterpillar for the machine meets the criteria of ISO 3471:2008, ISO 3449:2005 Level II.

lift capacity

Lift Capacity at Tipping Point40800.0 kg

BENEFITS AND FEATURES

572R2 STANDARD EQUIPMENT

- electrical

• Alarm, back-up

• Alternator, 70-amp

• Converter, 10-amp/12-volt

• Diagnostic connector (starting and charging)

• Horn, forward warning

• Hour meter

• Lights, 2 forward, 2 rear

• Starting receptacle, 24-volt direct - operator environment

• Armrests, adjustable

• Brake pedal

• Decelerator pedal and switch

• Engine air cleaner service indicator

• Engine RPM display/gear display

• Foot pegs for slope work

• FTC control for Clutch and Brake steering

• Monitoring System, Electronic (EMS III) coolant temperature, power train oil, hydraulic and fuel gauge, tachometer, odometer, gear indicator diagnostic functions

• Power points, two 12-volt

• Pre-start coolant level monitoring system

• Product Link Ready

• ROPS, rollover protection system

• Seat, vinyl suspension

• Seat belt, retractable 76 mm (3 in)

• Storage and literature compartment

• Transmission shift points selection

• Travel speed and gear limiter, electronic - pipelayer

• Block and hook with latch

• Boom, 6.10 m (20 ft)

• Counterweight, extendible segmented 4096 kg (9,030 lb)

• Hydraulics, pipelayer system - undercarriage

• Adjuster, hydraulic track

• Carrier rollers

• Heavy-duty sealed and lubricated tracks

• Lifetime lubricated idlers and track rollers

• Master link, two-piece

• Sprockets, segmented

• Track frame, 7 rollers

• Track with single grouser track shoes: – 43-section, 660 mm (26 in) - power train

• 3176C EUI Caterpillar diesel engine with: – Advanced Modular Cooling System (AMOCS) – Brake system, service, parking and emergency – Coolant, extended life – Drains, ecology (engine oil, coolant, hydraulic oil, fuel tank, power train case) – Fan, blower – Final drives, 3-planet double reduction planetary – Fuel priming pump – Fuel/Water separator – Grid, radiator core sand blast – Muffler – Precleaner with strata tube dust ejector – Prescreener – Starting aide, ether – Shifting, auto-shift (2F/2R, 2F/1R, 1F/2R) – Shifting, auto-kickdown (auto downshift) – Shifting, controlled throttle – Steering system, FTC Clutch and Brake – Torque divider – Transmission, power shift, three-speed planetary with torque converter - other standard equipment

• Altitude operation capability, 2286 meter (7,500 ft) without derating

• Bumper, front with towing device

• Diagnostic pressure taps, centralized ecology drains

• Extended service intervals (500 hours)

• Guards: – Crankcase, normal service – End track-guide – Hinged bottom – Instrument panel – Radiator, hinged – Rear

• Hood, perforated

• Implement oil filter

• Keyed lockable enclosures

• Load sensing hydraulics

• Radiator doors, louvered, hinged

• Rigid drawbar

• S•O•S analysis taps for engine, transmission, and implement fluids

• Transmission remote pressure taps

• Vandalism protection

572R2 OPTIONS

- operator environment

• Product Link PL321, none

• Product Link PL321, Satellite - pipelayer

• Boom, 7.3 m (24 ft) - power train

• Drain, ecology (transmission, torque converter)

MOTEUR

Integrated, robust components

BENEFITS AND FEATURES

Winches Independent hydraulic winches drive boom and hook draw works. The oil-disc brakes give you smooth operation, as well as positive retention of the boom and hook positions. Infinitely variable speed controls give your operator precise control, and a free-fall function allows your operator to drop the load quickly in the event of an emergency.

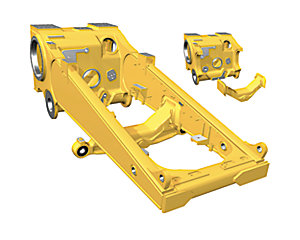

Counterweight A narrow profile of the counterweight design helps give your operators a better view around the machine. The box section frame, welded to a cast bevel gear case gives you a rugged mainframe design. The counterweight is extended hydraulically for better load balance and a service latch mechanically locks the counterweight in an extended position.

Boom The tubular cast steel boom is rugged to give you better fatigue life. Replaceable boom-mount bearings aid serviceability and long life. Your choice of a standard 6.10 m (20 ft) boom, or an optional 7.3 m (24 ft) boom, means you can equip the machine to best suit the demands of your operation.

Blocks and Hook The heavy-lifting, robust design is popular all around the pipeline industry. A counterweight latch gives you an added level of safety for servicing or inspection.

Drawbar A robust drawbar tows a wide range of attachments for maximum versatility.

Designed for Productive Comfort

BENEFITS AND FEATURES

Caterpillar designs operator stations for maximum productivity. Easy-to-use controls and operator comfort features, along with excellent visibility all around the machine not only help operators work more efficiently, but also contribute to enhanced job site safety.

- The standard Roll Over Protection Structure (ROPS) provides increased operator protection.

- Ergonomically designed seat is fully adjustable for maximum comfort. It is designed to give your operator excellent support, while still allowing unrestricted arm and leg movement. The position of the seat is well matched to key operator control levers and pedals. Foot pads help provide added stability when working on slopes.

- Finger Tip Controls put steering, machine direction, and gear selection into one easy-to-use control. Low-effort pipelayer controls give your operator simultaneous, precise positioning of the load line and boom in one hand.

- The instrument panel is easy to read, even in direct sunlight.

- An in-dash monitoring system provides the operator with instant feedback on fluid levels and temperatures, as well as the condition of key machine operating systems. The system performs a self-test at every start and provides fault codes for easy troubleshooting.

- A standard 12-volt converter supplies power for devices like cell phones and laptop computers.

- A convenient access ladder gives your operator direct access/egress to the operator station.

Powerful Efficiency

BENEFITS AND FEATURES

Engine The Cat 3176C engine gives you the large displacement and good cold start capabilities needed on challenging jobs. Its durable design has been proven in some of the world’s most challenging conditions and will provide years of dependable service.

Planetary Power Shift Transmission The electronically controlled planetary power shift transmission offers smooth shifting and agile speed and directional changes for maximum productivity. With three speeds forward and three speeds reverse, the transmission utilizes large diameter, high capacity, oil-cooled clutches for long life. Forced oil flow lubricates and cools clutch packs for long life.

Electronic Clutch and Brake Steering System Low-effort finger tip levers make steering easy and allow your operator to work more precisely in close areas and narrow right-of-ways.

Steering Clutch and Brakes Oil cooled, hydraulically actuated, large diameter plates and clutch discs provide higher torque capacity and increased service life.

Underlying Strength

BENEFITS AND FEATURES

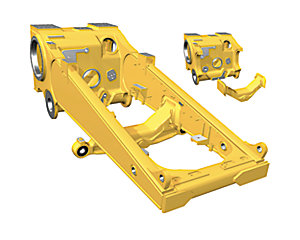

The Pipelayer main frame is engineered to handle the most demanding applications. The mainframe is built to absorb high impact shock loads and twisting forces. The one-piece all-welded chassis provides superior strength over bolted designs, as well as an optimum structure for pipelayer mounting. Heavy steel castings add strength to the main case, center saddle and front cross member for outstanding durability. The final drives are elevated well above the ground level work area to protect them from impact loads, abrasion and contaminants.Caterpillar uses robotic welding techniques in the assembly of the case and frames. The deep penetration and consistency of robotic welding insures quality for long life and durability.

Engineered for Performance

BENEFITS AND FEATURES

The 572R2 features a rigid Cat elevated sprocket undercarriage that isolates the final drives away from abrasive conditions. A long track roller frame and wide gauge give you more track contact area for a very stable working base.Undercarriage components are built for long life and ease of serviceability. Rollers and idlers feature Duo-Cone™ seals to help prevent oil loss and dirt entry. Tubular roller frames resist bending and twisting, with added reinforcement where operating loads are highest. Cat sprocket segments are precision machined after heat treat for proper fit. Segments can be removed or replaced without breaking the track.Pipelayer track is designed for high-impact and high load applications. The Heavy-Duty Sealed and Lubricated Track permanently coats the track pin with a sealed-in lubricant. This minimizes metal-to-metal contact and virtually eliminates internal pin and bushing wear.

Solutions to Make Work Easier and More Efficient

BENEFITS AND FEATURES

Cat Product Link™ * Remote monitoring with Product Link improves overall fleet management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink®. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more.*Product Link licensing not available in all areas.

Thinking Generations Ahead

BENEFITS AND FEATURES

- Technologies like Product Link help improve overall efficiency, save fuel and fluids, and reduce equipment wear and tear.

- Convenient access ladder, excellent visibility and easy-to-use controls enhance job site safety.

- Ecology drains make draining fluids more convenient and help prevent spills.

- Major components are built to be rebuilt, eliminating waste and saving customers money by giving the machine and/or major components a second – and even third – life.

More Productivity, Less Cost

BENEFITS AND FEATURES

Modular Design Major components are designed as modules and most can be removed without disturbing or removing other components. This means less service time and more working time for you.

Easy Diagnostics The machine monitoring system provides instant feedback on the condition of operating systems, utilizing a three level warning system. The system can easily be upgraded by flashing software.

Service Access Major service points are grouped to make your regular maintenance quicker and easier. Large service panel doors provide easier access to all maintenance locations.

Scheduled Oil Sampling (S∙O∙SSM) Analysis Monitor machine health and identify key maintenance needs before they lead to downtime through Cat Scheduled Oil Sampling. Cat machines feature live sampling ports for the engine oil, power train hydraulics and coolant. Cat oil sampling offers accurate analysis using tests designed by Caterpillar for Cat products, as well as knowledgeable interpretation of the results.

Ecology Drains Ecology drains provide a convenient method for draining fluids that saves time and helps prevent spills.

Designed with Protection in Mind

BENEFITS AND FEATURES

Job site safety is a key concern for pipeline customers, and Cat pipelayers are designed with features to help protect people in and around the machine.

- The standard Roll Over Protective Structure (ROPS) provides increased operator protection.

- The winch profile and overall machine design allow for excellent visibility around the machine.

- A long track roller frame and wide gauge give you more track contact area for a very stable working base.

- A left-side access ladder provides convenient access/egress to the operator station.

- A free-fall function allows your operator to drop the load quickly in the event of an emergency.

When Uptime Counts

BENEFITS AND FEATURES

Cat dealers excel at providing parts availability and equipment service to even the most remote areas. With more than 10,000 service technicians employed in over 3,000 Cat dealer locations around the world, Caterpillar parts and service resources and capabilities are beyond compare.From helping you choose the right machine to knowledgeable ongoing support, Cat dealers provide the best in sales and service. Manage costs with preventive maintenance programs like Custom Track Service, Scheduled Oil Sampling (S·O·S) analysis, and guaranteed maintenance contracts. Stay productive with best-in-class parts availability. Cat dealers can even help you with operator training to help you boost your profits.And when it’s time for machine replacement, your Cat dealer can help you save even more with Genuine Cat Reman parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent for power train and hydraulic components.