12M3 MOTOR GRADER

The hard working 12M3 gives you the muscle you need for everyday jobs like road maintenance and snow removal. Like all M Series 3 motor graders, this machine offers the best in productivity and operator comfort.

SPECIFICATIONS

Base Power (1st gear) - Net133.0 kW

Engine ModelCat® C9.3 ACERT™

Bore115.0 mm

BENEFITS AND FEATURES

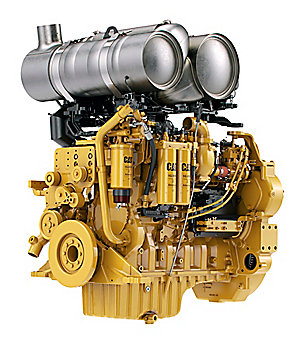

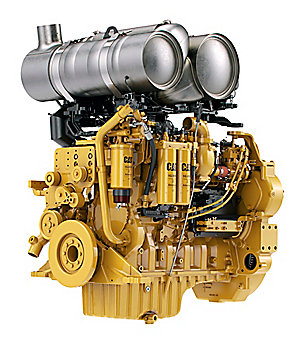

engine

Base Power (1st gear) - Net133.0 kW

Engine ModelCat® C9.3 ACERT™

Bore115.0 mm

Stroke149.0 mm

Speed @ Rated Power2,000 rpm

Base Power (1st gear) - Net (Metric)133.0 kW

EmissionsU.S. EPA Tier 4 Final/EU Stage IV

High Ambient - Fan Speed - Standard1,400 rpm

Maximum Torque (VHP Plus)1138.0 N·m

Standard Capability43.0 ° C

Torque Rise38%

VHP Plus Range - Net133-172 kW (179-231 hp)

VHP Plus Range - Net (Metric)133-172 kW (181-234 hp)

VHP Plus: Gear - Net Power - Forward - 1st133.0 kW

VHP Plus: Gear - Net Power - Forward - 2nd141.0 kW

VHP Plus: Gear - Net Power - Forward - 3rd149.0 kW

VHP Plus: Gear - Net Power - Forward - 4th156.0 kW

VHP Plus: Gear - Net Power - Forward - 5th160.0 kW

VHP Plus: Gear - Net Power - Forward - 6th164.0 kW

VHP Plus: Gear - Net Power - Forward - 7th168.0 kW

VHP Plus: Gear - Net Power - Forward - 8th172.0 kW

VHP Plus: Gear - Net Power - Reverse - 1st133.0 kW

VHP Plus: Gear - Net Power - Reverse - 2nd141.0 kW

VHP Plus: Gear - Net Power - Reverse - 3rd-6th149.0 kW

Displacement9.3 L

Number of Cylinders6

Derating Altitude3050.0 m

High Ambient - Fan Speed - Maximum1,550 rpm

High Ambient - Fan Speed - Minimum500 rpm

High Ambient Capability50.0 ° C

weights

Operating Weight - Typically Equipped19344.0 kg

Gross Vehicle Weight - Maximum - Front Axle7745.0 kg

Gross Vehicle Weight - Maximum - Rear Axle17268.0 kg

Operating Weight, Typically Equipped - Front Axle5468.0 kg

Operating Weight, Typically Equipped - Rear Axle13876.0 kg

Gross Vehicle Weight - Base - Front Axle4238.0 kg

Gross Vehicle Weight - Base - Rear Axle12736.0 kg

Gross Vehicle Weight - Maximum - Total25013.0 kg

Gross Vehicle Weight - Base - Total16974.0 kg

Operating Weight, Typically Equipped - Total19344.0 kg

moldboard

Blade Width3.7 m

Moldboard - Height610.0 mm

Moldboard - Thickness22.0 mm

Arc Radius413.0 mm

Throat Clearance166.0 mm

Cutting Edge - Width152.0 mm

Cutting Edge - Thickness16.0 mm

End Bit - Width152.0 mm

End Bit - Thickness16.0 mm

Blade Pull - Base GVW11462.0 kg

Blade Pull - Maximum GVW15541.0 kg

Blade Down Pressure - Base GVW7275.0 kg

Blade Down Pressure - Maximum GVW13294.0 kg

Moldboard - Blade Width3.7 m

dimensions

Height - Top of Cab3308.0 mm

Length - Counterweight to Ripper10136.0 mm

Width - Outside Front Tires2511.0 mm

Length - Front Axle to Mid Tandem6123.0 mm

Length - Front Tire to Rear of Machine8912.0 mm

Length - Front Axle to Moldboard2552.0 mm

Length - Between Tandem Axles1523.0 mm

Width - Outside Rear Tires2511.0 mm

Width - Tire Center Lines2140.0 mm

Height - Front Axle Center596.0 mm

Height to Exhaust Stack3256.0 mm

Height to Top of Cylinders3040.0 mm

Ground Clearance at Rear Axle339.0 mm

operating specifications

Top Speed - Forward46.6 km/h

Top Speed - Reverse36.8 km/h

Turning Radius, Outside Front Tires7.8 m

Steering Range - Left/Right50°

Articulation Angle - Left/Right20°

Forward - 1st4.1 km/h

Forward - 2nd5.5 km/h

Forward - 3rd8.0 km/h

Forward - 4th11.0 km/h

Forward - 5th17.1 km/h

Forward - 6th23.3 km/h

Forward - 7th32.0 km/h

Forward - 8th46.6 km/h

Reverse - 1st3.2 km/h

Reverse - 2nd6.0 km/h

Reverse - 3rd8.7 km/h

Reverse - 4th13.5 km/h

Reverse - 5th25.3 km/h

Reverse - 6th36.8 km/h

service refill

Fuel Capacity394.0 L

Cooling System57.0 L

Hydraulic System - Total100.0 L

Hydraulic System - Tank64.0 L

Diesel Exhaust Fluid22.0 L

Trans./Diff./Final Drives70.0 L

Engine Oil30.0 L

Tandem Housing (each)76.0 L

Front Wheel Spindle Bearing Housing0.5 L

Circle Drive Housing7.0 L

power train

Forward/Reverse Gears8 Forward/6 Reverse

TransmissionAPECS, Direct Drive, Powershift

Brakes - ServiceMultiple Oil Disc

Brakes - Service, Surface Area23000.0 cm2

Brakes - ParkingMultiple Oil Disc

Brakes - SecondaryDual Circuit

hydraulic system

Circuit TypeParallel

Pump TypeVariable Piston

Pump Output210.0 L/min

Maximum System Pressure24150.0 kPa

Reservoir Tank Capacity64.0 L

Standby Pressure6100.0 kPa

frame

Drawbar - Width76.2 mm

Circle - Diameter1530.0 mm

Circle - Blade Beam Thickness40.0 mm

Drawbar - Height152.0 mm

Circle - Height138.0 mm

Front Frame Structure - Height321.0 mm

Front Frame Structure - Width305.0 mm

Drawbar - Thickness12.7 mm

Front-Top/Bottom Plate - Width305.0 mm

Front-Top/Bottom Plate - Thickness22.0 mm

Front Axle - Height to Center596.0 mm

Front Axle - Wheel Lean, Left/Right18°

Front Axle - Total Oscillation per Side32°

blade range

Circle Centershift - Right728.0 mm

Circle Centershift - Left695.0 mm

Moldboard Sideshift - Right660.0 mm

Moldboard Sideshift - Left510.0 mm

Maximum Blade Position Angle90°

Blade Tip Range - Forward40°

Blade Tip Range - Backward5°

Maximum Shoulder Reach Outside of Tires - Right1978.0 mm

Maximum Shoulder Reach Outside of Tires - Left1790.0 mm

Maximum Lift above Ground480.0 mm

Maximum Depth of Cut715.0 mm

standards

BrakesISO 3450

ROPS/FOPSISO 3471/ISO 3499

SoundISO 6394; ISO 6395

SteeringISO 5010

scarifier

Front, V-Type, 5 or 11 Tooth - Scarifier Shank Holder Spacing116.0 mm

Front, V-Type, 5 or 11 Tooth - Scarifier Shank Holders5/11

Front, V-Type, 5 or 11 Tooth - Scarifying Depth, Maximum467.0 mm

Front, V-Type, 5 or 11 Tooth - Working Width1031.0 mm

Front, V-Type: Working Width1205.0 mm

Mid, V-Type - Scarifier Shank Holder Spacing116.0 mm

Mid, V-Type - Scarifier Shank Holders11

Mid, V-Type - Scarifying Depth, Maximum292.0 mm

Mid, V-Type - Working Width1184.0 mm

Rear - Scarifying Depth, Maximum426.0 mm

Rear - Working Width2133.0 mm

Rear - Scarifier Shank Holders9

Rear - Scarifier Shank Holder Spacing267.0 mm

ripper

Ripper Shank Holder Spacing533.0 mm

Ripping Depth - Maximum426.0 mm

Ripper Shank Holders5

Penetration Force9440.0 kg

Pryout Force12607.0 kg

Machine Length Increase, Beam Raised1031.0 mm

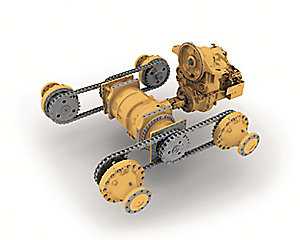

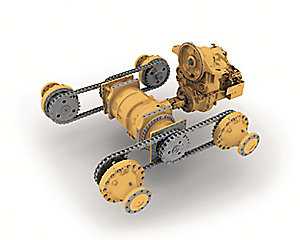

tandems

Height506.0 mm

Width201.0 mm

Sidewall Thickness - Inner16.0 mm

Sidewall Thickness - Outer18.0 mm

Drive Chain Pitch50.8 mm

Wheel Axle Spacing1523.0 mm

Tandem Oscillation - Front Up15°

Tandem Oscillation - Front Down25°

BENEFITS AND FEATURES

12M3 STANDARD EQUIPMENT

- power train

Air cleaner, dual stage, dry type, diesel, with automatic engine derate and automatic dust ejector, service indicator through Cat Messenger

Air-to-air after cooler (ATAAC)

Belt, serpentine, automatic tensioner

Brakes, oil disc, four-wheel, hydraulic

Demand fan, hydraulic, swing-out

Diesel exhaust fluid tank, 22.0 L (5.8 gal) ground level access, and sediment drain

Differential Lock/Unlock, Automatic

Drain, engine oil, ecology

Economy mode

Electronic over speed protection

Engine, C9.3 with ACERT Technology, U.S. EPA Tier 4 Final/EU Stage IV emission standards

Fuel tank, 394 L (104 gal), ground level access and sediment drain

Parking brake - multi-disc, sealed, oil-cooled

Priming pump, fuel

Rear axle, modular

Sediment drain, fuel tank

Tandem drive

Transmission, 8F/6R, powershift, direct drive, Advanced Productivity Electronic Control Strategy (APECS) - electrical

Alarm, back up

Alternator, 150 ampere, sealed

Batteries, maintenance free, heavy duty, 1125 CCA

Breaker panel, ground accessible

Cab harness and electrical hydraulic valves

Electrical system, 24V

Grade Control Ready - Cab harness, software, electrical hydraulic valves, bosses and brackets

Lights, roof-mounted roading, reversing, LED stop and tail

Product Link

Starter, electric - operator environment

Accelerator

Air conditioning with heater

Arm and wrist rest, electronically adjustable

Articulation, automatic Return-to-Center

Cat Messenger operator information system

Centershift pin indicator

Coat hook

Cup holder

Display, digital speed and gear

Doors, left and right side with wiper

Gauge, machine level

Gauge cluster (analog) - fuel, articulation, engine coolant temp, engine RPM, hydraulic oil temp, regen, DEF

Hour meter, digital

Joystick hydraulic controls right/left blade lift with float position, circle drive, blade sideshift and tip, centershift, front wheel lean, articulation and power steering

Joystick, adjustable armrests

Joystick gear selection

Joystick hydraulic power steering

Ladders, cab, left and right side

Lights, night time cab

Mirror, inside rearview, wide angle

Power port, 12V

Radio Ready, Entertainment

ROPS cab, sound suppressed 70 dB(A)

Seat, cloth-covered, comfort suspension

Seat belt, retractable 76 mm (3 in)

Storage area for cooler/lunchbox

Throttle control, electronic

Windows, laminated glass: - fixed front with intermittent wiper - door with intermittent wipers (3)

Windows: tempered: - left and right side wipers - rear and intermittent wiper - fluids

Antifreeze

Extended Life Coolant to -35° C (-30° F) - tires rims and wheels

Partial allowance for tires on 254 × 607 mm (10 × 24 in) multi-piece rims is included in the base machine price and weight - other standard equipment

Accumulators, brake, dual certified

Anti-glare paint

Bumper, rear, integrated with hitch

CD ROM Parts Book

Clutch, circle drive slip

Cutting edges: - 152 × 16 mm (6 × 5/8 in) - curved DH-2 steel - 19 mm (3/4 in) mounting bolts

Doors (3), engine compartment, locking

Drawbar - 6 shoes, replaceable wear strips

Electrical hydraulic valves, hydraulic lines for base 8 functions

Endbits: - 16 mm (5/8 in) DH-2 steel - 19 mm (3/4 in) mounting bolts

Fluid check, ground level

Frame, articulated, with safety lock

Ground level engine shutdown

Hammer (emergency exit)

Horn, electric

Hydraulic lines for base functions

Lockout, hydraulic implement (for roading and servicing)

Moldboard

Mounting, cab roof accessories

Pump, hydraulic, high capacity, 98 cm³ (6 in³)

Radiator, cleanout access (both sides with swing doors)

Secondary steering

Serviceability, LH side

S·O·SSM ports: engine, hydraulic, transmission, coolant, fuel

Tandem walkway/guards

Tool box

12M3 OPTIONS

- electrical

Alternator, 280 ampere

Batteries: extreme duty, 1,400 CCA

Lights: Headlights, high

Lights: Headlights, low

Lights: Working lights, basic

Lights: Working lights, plus

Lights: Warning: beacon or strobe

Lights: Mounting for warning light - guards

Articulation guard

Fenders, front

Fenders, rear

Front axle guard

Sound suppression (bottom)

Sound suppression (enclosure)

Transmission - operator environment

Mirrors, outside: heated 24V

Mirrors, outside: mounted

Comfort Plus Arrangement

Comfort Premium Arrangement - power train

All Wheel Drive

Precleaner, snow

Starter, extreme duty, 1,000 Amps

Transmission, autoshift - other attachments

AccuGrade ARO

Integrated cross slope

Accumulators, blade lift

Camera, rearview

Cat Product Link 321SR

Cat Product Link 522

Drain, ecology, engine Wiggins

Heater, engine coolant: 120V

Heater, engine coolant: 240V

Hydraulic arrangements with one or more additional hydraulic valves are available for rear ripper, dozer, snow plow and snow wing.

Snow wing mounting, frame ready

Starting aid, ether - work toolsget

Blade extension, left hand, 610 mm (2 ft)

Blade extension, right hand, 610 mm (2 ft)

Counterweight

Cutting edges, curved

Endbits, overlay

Front lift group, mounting

Front lift group, mechanical

Grader bit, narrow and super penetration

Mid-Mount Scarifier, Package

Moldboard: 4267 mm × 610 mm × 22 mm (14 ft × 24 in × 7/8 in)

Moldboard: 4267 mm × 686 mm × 25 mm (14 ft × 27 in × 1 in)

Push plate

Ripper, rear

Ripper tooth

Scarifier, front

Snow Arrangement

Snow Wing Ready Package

Tow hitch - machine arrangements

Canadian Arrangement

European Arrangement

TUV Roading Arrangement - optional tire arrangements

Rim Size - 9 × 24; Wheel Group - Single-Piece; Tires - 14.0R24

Rim Size - 13 × 25; Wheel Group - Single-Piece; Tires - 17.5R25

Rim Size - 10 × 24; Wheel Group - Multi-Piece; Tires - 14.0R24

Rim Size - 10 × 24; Wheel Group - Multi-Piece; Tires - 14.0-24

Rim Size - 14 × 25; Wheel Group - Multi-Piece; Tires - 17.5R25

Rim Size - 14 × 25; Wheel Group - Multi-Piece; Tires - 17.5-25

Note: Consult your dealer for individual tire width, size and brand.

MOTEUR

Comfort, productivity, advanced technology

BENEFITS AND FEATURES

Visibility Good visibility is key to your safety and efficiency. Angled cab doors, tapered engine enclosure and a sloped rear window make it easy to see the moldboard and tires, as well as behind the machine. An optional rear vision camera further enhances lines of sight all around the machine.

In-Dash Instrument Cluster A redesigned message display shows machine performance and diagnostic information, including DEF tank levels. Now located in the center console, it also displays Cat Grade Control Cross Slope readings conveniently in front of the operator.

Comfort and Control Experience the most comfortable cab in the industry. Joystick controls replace levers, so hand and arm movement is reduced by 78%, helping reduce operator fatigue for better productivity. Rocker and control switches are in easy reach. An updated seat with softer cushions and three-position cushion tilt adds to your overall comfort. You can even upgrade to a heated or heated/ventilated seat. An optional seat belt indicator feature is also available. Control pods can be adjusted electronically, making it easy to set your ideal operating position. Multiple isolation mounts significantly reduce sound and vibration for a more relaxed work environment. The high capacity Heating, Ventilation and Air Conditioning (HVAC) system dehumidifies and pressurizes the cab, seals out dust and helps keep windows clear. Pop-out louvers circulate fresh air. An optional deluxe radio with CD features MP3 and Bluetooth technology.

Unprecedented precision and ease of operation

BENEFITS AND FEATURES

Two electro-hydraulic joysticks with electronically adjustable control pods help position operators for optimal comfort, visibility and productive operation.

Joystick Functions The left joystick controls machine direction, steering, articulation, return-to-center, wheel lean, gear selection, left moldboard lift cylinder and float. The right joystick controls drawbar, circle and moldboard functions as well as electronic throttle control and manual differential lock/unlock. The steer tire angle matches the joystick position. A brake tensioning system holds the joystick in position until the operator moves it. The steering control automatically reduces steering sensitivity at higher ground speeds for predictable control. Infinitely variable roller switches control the rear ripper and/or front lift group (when equipped). Optional Programmable Auxiliary Hydraulic Pod controls up to six additional hydraulic circuits.

Electronic Throttle Control Electronic Throttle Control helps improve productivity by providing the best match of horsepower and torque for the demands of the application.

Articulation Return-to-Center Automatically returns the machine to a straight frame position from any angle with the touch of a button.

Selectable Blade Lift Modes Choose the blade lift modulation mode that best fits your application or operating style: Fine, Normal, or Coarse.

Power and reliability

BENEFITS AND FEATURES

A Cat C9.3 ACERT engine gives you the performance you need to maintain consistent grading speeds for maximum productivity. Every U.S. EPA Tier 4 Final/EU Stage IV ACERT engine is equipped with a combination of proven electronic, fuel, air and aftertreatment components. Applying proven technologies systematically and strategically helps meet your high expectations for productivity, fuel efficiency, reliability and service life.

Hydraulic Demand Fan The hydraulic demand fan automatically adjusts speed according to cooling requirements. When cooling demand is reduced, you benefit from more power to the ground and improved fuel efficiency.

Engine Idle Shutdown Timer This standard feature can be software-enabled by your Cat dealer to shut down the engine after a set period of time to save you fuel and help reduce emissions.

Proven, integrated solutions

BENEFITS AND FEATURES

Emissions reduction technology on the M Series 3 Motor Grader is designed to be transparent, with no action required from the operator. There is no need to stop. Regeneration runs automatically at cold start-up and, if needed, in the background while you work.

Aftertreatment Technologies Caterpillar designed Tier 4 Interim products with Tier 4 Final standards in mind. To meet the additional 80 percent reduction in NOx emissions required by EPA Tier 4 Final/EU Stage IV emission standards, Caterpillar engineers only needed to add one new system to the already proven aftertreatment solution in use, Selective Catalytic Reduction (SCR).

Diesel Exhaust Fluid Selective Catalytic Reduction utilizes Diesel Exhaust Fluid (DEF), which can be conveniently filled from ground level. Simply refill the DEF tank when you refuel. A gauge on the dash shows your fluid level. When you turn the machine off, a pump will automatically purge the DEF lines. A light located inside the rear engine compartment will turn off, telling you the purge is complete and that it is safe to turn off the electrical disconnect. If the engine/aftertreatment temperatures are high, a Delayed Engine Shutdown will activate automatically to cool the machine and then purge the lines. For complete aftertreatment information, please refer to your machine’s Operation and Maintenance Manual.

Maximum power to the ground

BENEFITS AND FEATURES

- Standard Automatic Differential Lock/Unlock monitors machine and application parameters to unlock/re-lock the differential during operation, improving production and enhancing comfort while protecting the power train.

- Full Electronic Clutch Pressure Control optimizes inching modulation for smooth shifts and directional changes.

- Programmable Autoshift option simplifies operation by allowing you to program the transmission to shift at optimal points to match your application.

- New standard Economy Mode can be turned on to help save fuel by reducing engine speed so the machine works in a more efficient range. The average fuel savings is up to 10 percent, depending on the application.

- Power Shift Countershaft Transmission maximizes power to the ground.

- Engine Over-Speed Protection prevents downshifting until an acceptable safe travel speed has been established.

Front and Rear Axles The sealed spindle keeps front axle bearings lubricated and protected from contaminants. The Cat “Live Spindle” design places the larger tapered roller bearing on the outside, where the load is greater, extending bearing life. A bolt-on modular rear axle improves serviceability and contamination control with easy access to differential components.

Hydraulic Brakes Oil-bathed multi-disc service brakes are hydraulically actuated for smooth, predictable braking and lower operating costs. Brakes are located at each tandem wheel and have a large total brake surface area to give you dependable stopping power and longer life.

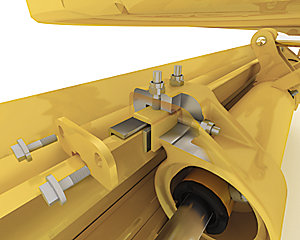

Service ease and precise blade control

BENEFITS AND FEATURES

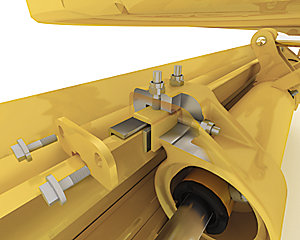

Caterpillar designs motor grader frame and drawbar components to give you performance and durability. The one-piece forged steel circle stands up to high stress loads, and a sacrificial wear system helps keep your service time and costs down. The articulation hitch features a large tapered roller bearing to carry loads evenly and smoothly. It is sealed to prevent contamination and a locking pin prevents articulation for safety during service or transport.

Easy Maintenance for More Uptime The drawbar, circle and moldboard are designed to make it easy to keep the components tight. One person can easily adjust or replace the patented top-adjust drawbar wear inserts from the top of the drawbar plate, reducing downtime to save you money. Durable nylon composite wear inserts maximize circle torque and component life. Sacrificial brass wears strips between the blade mounting group and moldboard can be easily adjusted and replaced. The Shimless Moldboard Retention System uses vertical and horizontal adjusting screws to keep moldboard wear strips aligned for reduced blade chatter and precise blade control.

Blade Angle and Moldboard An aggressive blade angle, optimized moldboard curvature and large throat clearance help you work more efficiently by allowing material to roll more freely along the blade. Heat-treated rails, hardened cutting edges and end bits, and heavy duty bolts to give you greater moldboard reliability and long service life. The link bar allows extreme moldboard positioning for easier bank sloping and ditch cutting/cleaning.

Advanced machine control

BENEFITS AND FEATURES

Responsive Hydraulics A proven load-sensing system and advanced electro-hydraulics give you superior implement control and responsive hydraulic performance that helps make your operator’s job easier. Continuously matching hydraulic flow/pressure to power demands creates less heat and reduces power consumption.

- Consistent, Predictable Movement - Proportional Priority Pressure-Compensating (PPP-C) valves have different flow rates for the head and rod ends of the cylinder, so you can count on consistent, predictable implement response.

- Balanced Flow - Hydraulic flow is proportioned to give you confidence that all implements will operate simultaneously without slowing the engine or speed of some implements.

Blade Float Allows the blade to move freely under its own weight. By floating both cylinders, the blade can follow the contours of the ground. Floating only one cylinder permits the toe of the blade to follow a hard surface while the operator controls the slope with the other lift cylinder.

Independent Oil Supply Large, separate hydraulic oil supplies prevent cross-contamination and provide proper oil cooling, which reduces heat build-up and extends component life. Cat XT™ hose allows high pressures for maximum power and reduced downtime.

Monitor, manage, and enhance job site operations

BENEFITS AND FEATURES

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you’ll get more information and insight into your equipment and operations than ever before. Cat Connect technologies offer improvements in these key areas: Equipment Management - increase uptime and reduce operating costs. Productivity - monitor production and manage job site efficiency. Safety - enhance job site awareness to keep your people and equipment safe. Featured Cat Connect technologies include:

Link Link technologies provide wireless capability to machines enabling two-way transfer of information collected by on-board sensors, control modules, and other Cat Connect technologies using off-board apps, such as our VisionLink software.

Product Link™/VisionLink® Product Link takes the guesswork out of equipment management. Track location, hours, fuel usage, productivity, idle time, diagnostic codes and more through the online VisionLink interface. Manage your fleet in real time so you can maximize efficiency, improve productivity, and lower operating costs.

Grade Grade technologies combine digital design data, in-cab guidance, and automatic blade controls to enhance grading accuracy, reduce rework, and lower costs related to production earthmoving and rough, fine and finish grade applications.

Cat Grade Control Cross Slope Cat Grade Control Cross Slope is an optional fully integrated, factory installed system that helps your operator improve grading efficiency and more easily maintain accurate cross slopes. The system automatically controls one side of the blade, reducing manual operator inputs by as much as 50 percent. Experienced operators can maintain peak efficiency levels throughout more of the work day, while less experienced operators can be more productive faster. The system is job-ready from day one, and scalable for the future with AccuGrade™ upgrade kits that provide additional 2D and/or 3D control.

Cat AccuGrade AccuGrade is an optional dealer-installed grade control system that provides higher accuracy capabilities to the Cat Cross Slope system by adding Sonic, Laser, GPS, and/or Universal Total Station (UTS) technology when the job requires. In-cab guidance helps operators work more confidently and get to grade faster, in fewer passes, using less material, improving productivity and accuracy by nearly 50 percent over conventional methods. Grade stakes and checkers are minimized, making the job site safer and more cost effective. An AccuGrade Attachment Ready Option can be ordered as a factory or dealer-installed option. It includes built-in mounting points and internal wiring for easy installation of the AccuGrade system.

Designed with protection in mind

BENEFITS AND FEATURES

Operator Presence Monitoring System Standard system keeps the parking brake engaged and hydraulic implements disabled until the operator is seated and the machine is ready for operation.

Speed Sensitive Steering Standard function makes steering less sensitive as ground speed increases for greater operator confidence and control.

Secondary Steering System Standard feature automatically engages an electric hydraulic pump in case of a drop in steering pressure so the operator can steer the machine to a stop.

Hydraulic Lockout Disables all implement functions while still providing machine steering control. This standard safety feature is especially useful while roading.

Brake Systems Brakes are located at each tandem wheel to eliminate braking loads on the power train. Redundant brake systems utilize accumulators to enable stopping in case of machine failure.

Walkways and Grab Rails Perforated steel tandem walkways and convenient grab rails give you a sturdy platform when moving on, off and around the machine.

Circle Drive Slip Clutch Protects the drawbar, circle and moldboard from shock loads when the blade encounters an immovable object. This standard feature also reduces the possibility of abrupt directional changes in poor traction conditions.

Blade Lift Accumulators Help absorb impact loads to the moldboard by allowing vertical blade travel. This optional feature helps reduce wear and aids operator safety.

M Series 3 Safety Features

- Optional rearview camera with in-cab monitor

- New optional seat belt indicator light reminds operator to fasten safety belt

- Grouped, ground level service points

- Laminated front window glass

- Optional LED Lighting

- Ground-level electrical disconnect switch

- Ground-level engine shutoff switch

- Anti-glare paint eases night operation

- Optional front and rear fenders

Equip your machine for the job

BENEFITS AND FEATURES

Moldboard Options The 12M3 motor grader comes equipped with a 3.7 m (12 ft) moldboard. An optional 4.3 m (14 ft) blade is also available.

Ground Engaging Tools (GET) A variety of tools are available from Cat Work Tools, including cutting edges, graderbits and end bits, all designed for maximum service life and productivity.

Front Mounted Groups A front mounted push plate or front lift group are available. The front lift group can be combined with a front dozer blade or front scarifier for added versatility.

Rear Ripper/Scarifier Made to penetrate tough material fast and rip thoroughly for easier movement with the moldboard. The ripper includes three shanks (with holders for five). Nine scarifier shanks can also be added for additional versatility.

Snow Removal Work Tools Snow plow, snow wing and mounting options increase machine versatility and utilization throughout the year.

Advanced Diagnostics

BENEFITS AND FEATURES

- Cat Messenger, combined with full systems integration, enhances diagnostic capability for quick analysis of critical data.

- Electronic Technician (Cat ET) lets service technicians access stored diagnostic data and configure machine parameters through the Cat Data Link.

- Low Battery Elevated Idle raises idle speed when low system voltage is detected, ensuring adequate system voltage and improving battery reliability.

- Automatic Engine Deration protects the engine by automatically lowering engine torque output and alerting the operator if critical conditions are detected.

When uptime counts

BENEFITS AND FEATURES

Cat motor graders are designed to help you increase uptime and reduce costs. Grouped service points and extended service intervals save maintenance time. New optional LED lights in the left hand compartment makes it more convenient to service the machine in low light.

Unparalleled Dealer Support When it comes to supporting you, Cat dealers are second to none. From machine selection and purchase to maintenance support and rebuilds, Cat dealers have the experience and capabilities to help keep you up and running.

Thinking generations ahead

BENEFITS AND FEATURES

Fuel Efficiency

- Integrated machine systems and technologies improve productivity for greater accuracy, allowing the machine to do more work per gallon of fuel.

- New Economy Mode feature allows the machine to work in the most efficient engine speed range to help reduce fuel use.

Green House Gas Emissions

- Reduced fuel consumption means reduced CO2 emissions.

- M Series 3 Motor Graders meet U.S. EPA Tier 4 Final/EU Stage IV emission standards.

Material Efficiency and Lifecycle Costs

- Replaceable wear parts save maintenance time and cost, and extend major component life.

- Major components are built to be rebuilt, eliminating waste and saving customers money by giving the machine and/or major components a second - and even third - life.

- Approximately 95% of machine materials can be recycled (ISO 16714) to conserve valuable natural resources and further enhance machine end-of-life value.

Sound • Reduced engine noise and quieter cabs mean lower operator and spectator sound levels.

Safety

- Ecology drains help make draining fluids more convenient and help prevent spills.

- Cartridge style hydraulic fluid filters provide safe clean draining of filters prior to replacement, helping to prevent fluid spills.

- A variety of safety features help safeguard operators and others on the job site.