6020B HYDRAULIC SHOVEL

You need a shovel that works. A simple, durable digger that gets the job done efficiently and safely. The Cat 6020B is engineered from the ground up with ease of use in mind. It’s easy to assemble, easy to learn, easy to operate and easy to maintain. So you can concentrate on running a safe, productive operation. The new Cat 6020B. It’s not complicated.

SPECIFICATIONS

Engine Output – SAE J1995778 kW (1,043 hp)

Standard Bucket CapacityBackhoe (heaped 1:1) 12.0 m3 (15.7 yd3)

Operating WeightBackhoe -- 224 tonnes (247 tons)

BENEFITS AND FEATURES

stateoftheart operator’s cab

Protecting and Supporting Your Most Important Asset: the Operator

LEARN MORE

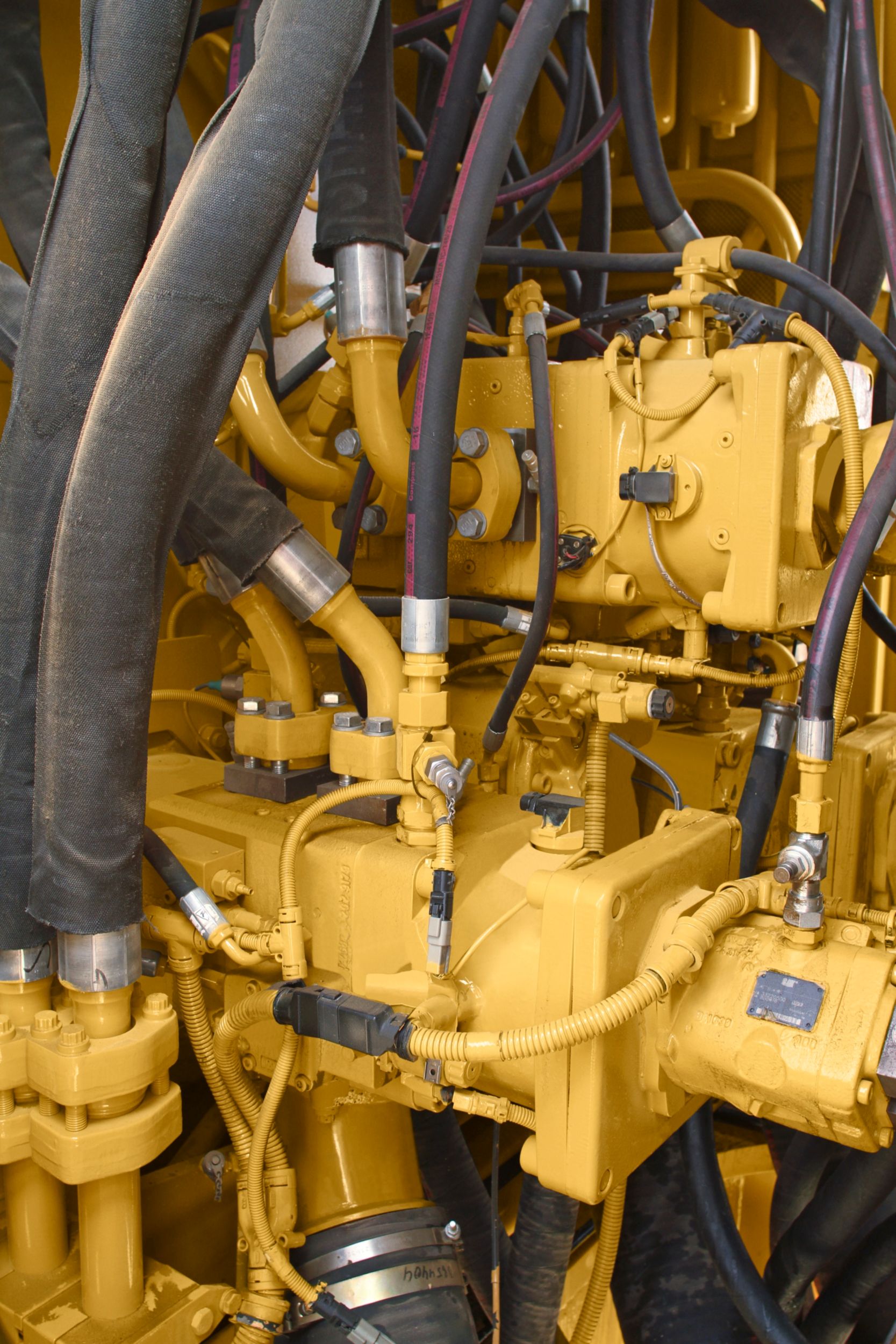

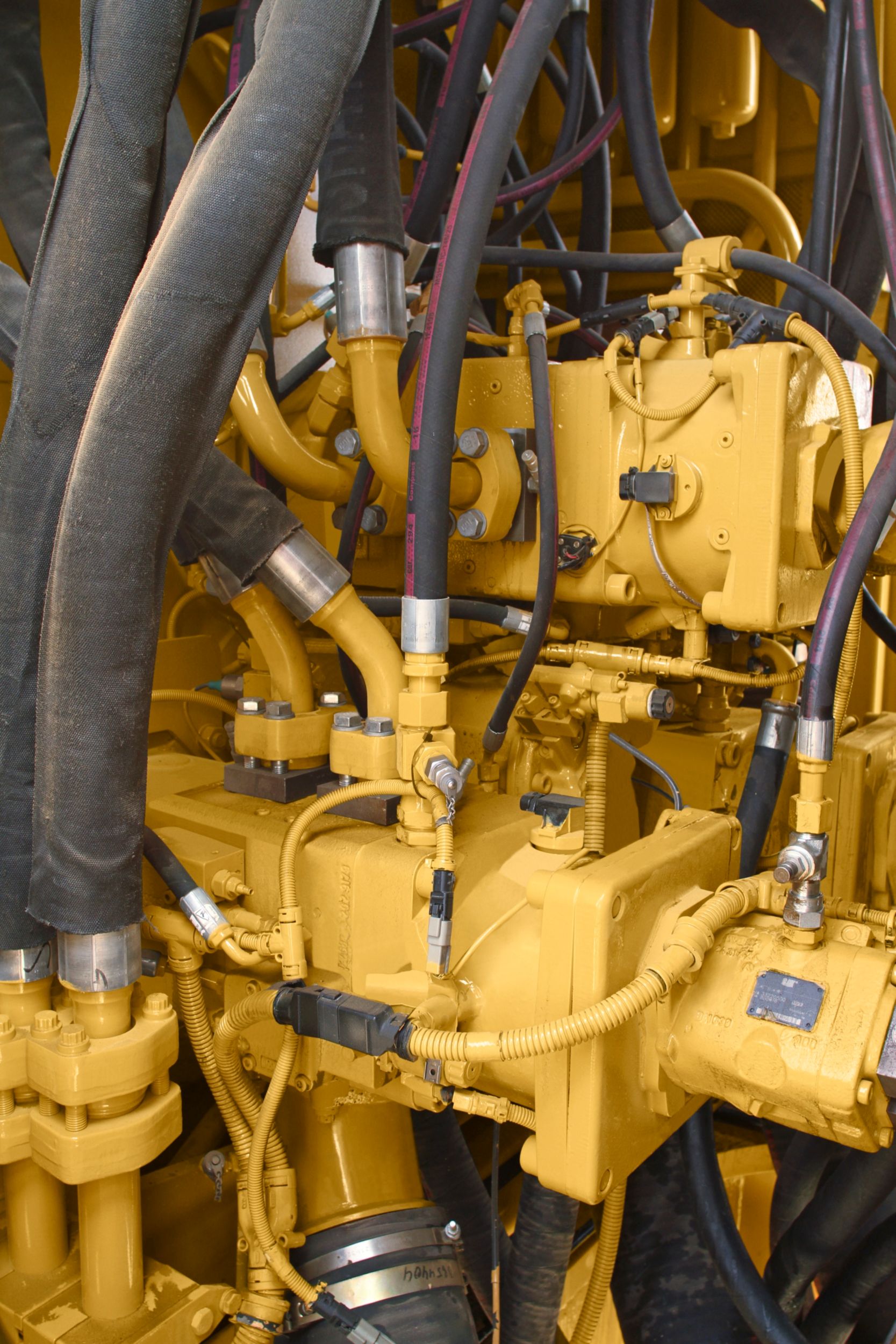

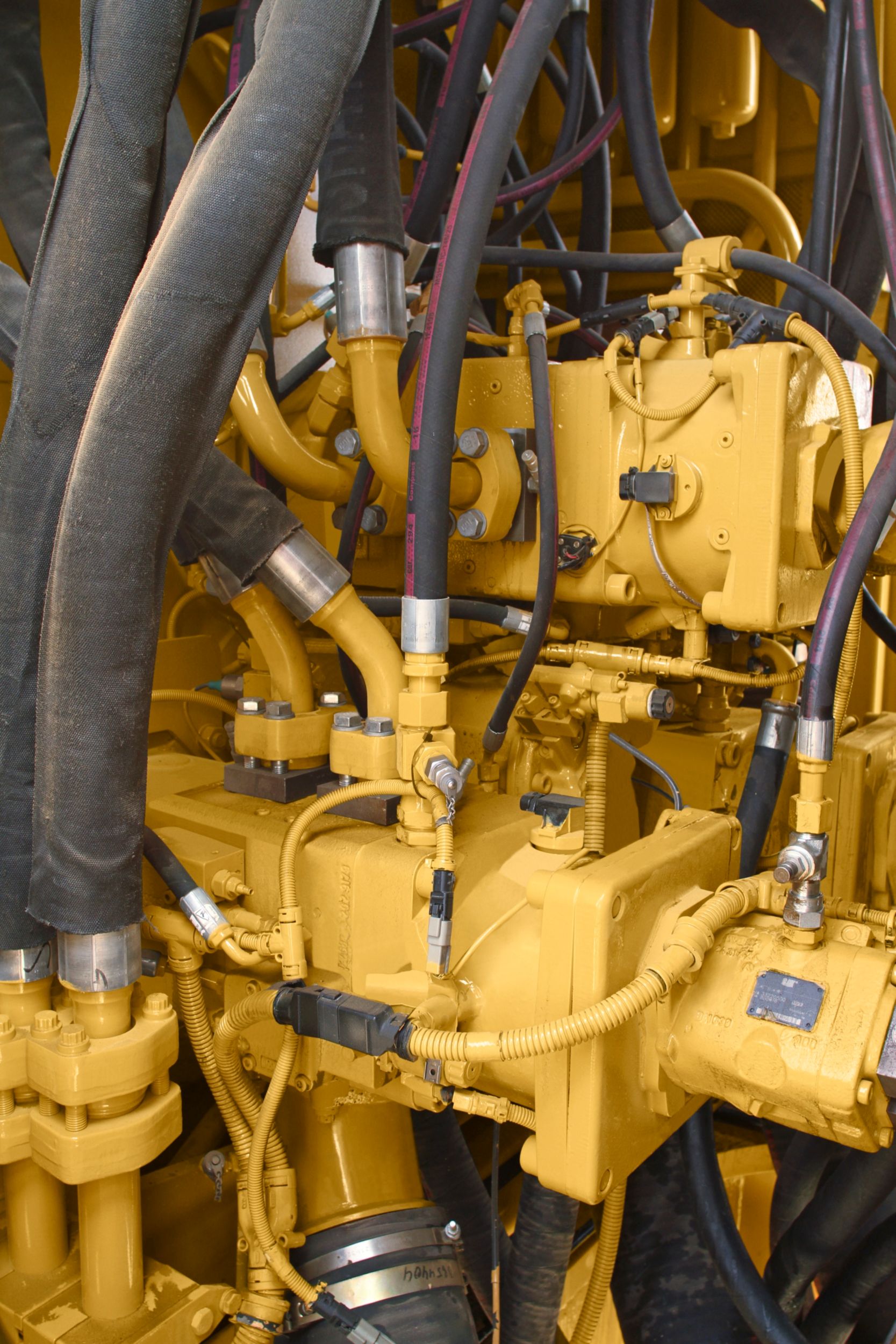

advanced hydraulic system

Reliable Performance from an Efficient, Clean, and Serviceable System

LEARN MORE

general data

Engine Output – SAE J1995778 kW (1,043 hp)

Standard Bucket CapacityBackhoe (heaped 1:1) 12.0 m3 (15.7 yd3)

Operating WeightBackhoe -- 224 tonnes (247 tons)

operating weight – backhoe

Ground Pressure21.7 N/cm2 (31.4 psi)

Operating Weight224000 kg

Standard Track Pads800.0 mm

centralized service area

Equipped with:Quick couplings for: – Diesel fuel – Engine coolant – Pump transmission gear oil – Engine oil (oil pan) – Hydraulic oil

Equipped with:Cat jump-start socket

Equipped with:Indicator light for hydraulic tank full

FeaturesCentralized service area accessible from ground level.

backhoes

Capacity 1:112.0 m3

Capacity 2:110.6 m3

Capacity Struck9.2 m3

Inner Width3000.0 mm

Maximum Material Density (loose)1.8 t/m³ (3,030 lb/yd³)

No. of Teeth6

Tooth SystemCat C85 system

Total Width3450 mm

TypeStandard rock bucket

Weight including standard wear package12800 kg

electrical system

System Voltage24V

Batteries (12V each)6 × 210 Ah

Batteries (12V each) – In Series/Parallel Installation630 Ah – 24V

Battery isolation relaysmanual lockable disconnect switch and automatic disconnect relay

ComponentsEmergency stop buttons inside cab, accessible from all seating locations, and engine module

ComponentsAdditional ground-level emergency stop

Components8 LED high-brightness working flood lights: – 6 for working area – 2 for rear end

Components2 LED high-brightness access flood lights

Components7 LED service lights

Components1 beacon lamp on cab roof

diesel engine

Alternator275A

AspirationTurbocharged and air-to-air aftercooled

Bore145.0 mm

ComponentsHydraulically driven radiator fan with variable electronically controlled fan speed

ComponentsReversible fan for self cleaning of engine radiator

ComponentsMicro processed engine management

ComponentsHeavy-duty air filters

ComponentsTwo-stage fuel filter

ComponentsAdditional high-capacity water separator including electric priming pump

ComponentsLarge fuel tank allows for 24 hour machine operation

Displacement32.0 L

Emission CertificationU.S. EPA Flex

Fuel Tank Capacity3600.0 L

Make and ModelCat C32 (Tier 2)

Maximum Altitude without Deration above sea level (a.s.l.)2000.0 m

No. of Cylinders12

Rated Gross Power SAE J1995778 kW (1,043 hp, 1,800 min-1)

Rated Net Power ISO 3046/1778 kW (1,043 hp, 1,800 min-1)

Rated Net Power SAE J1349778 kW (1,043 hp, 1,800 min-1)

Stroke162.0 mm

attachment

Buckets equipped with:– Special liner material covering main wear areas inside and outside – Lip shrouds – Wing shrouds – Heel shrouds

TypeBoom and stick torsion-resistant with welded box design

TypeHigh‑tensile steel with solid steel castings at pivot areas

TypeBoom and stick stress-relieved after welding

TypeCatwalks with rails at boom

TypeFloat valve for boom down function

hydraulic system with electronic pump management

Electronic pump management contains:Electronic load limit control

Electronic pump management contains:Dedicated circuit pump allocation

Electronic pump management contains:Automatic return of main pumps to zero flow

Electronic pump management contains:Automatic rpm reduction of engine speed during working breaks

Electronic pump management contains:Reduced oil flow of main pumps at high hydraulic oil temperature and at high engine temperature

FeaturesPressure cut-off function for all main pumps

FeaturesCooling of pump transmission gear oil

Filters:Full-flow high-pressure filters (100 μm) for main pumps, installed directly behind each pump

Filters:Full-flow filters (10 μm) for complete return circuit

Filters:Full-flow filters (10 μm) for cooling return circuit

Filters:Pressure filters (6 μm) for servo circuit

Filters:Transmission oil filter (40 μm)

Main Pumps6 × variable swash plate pumps

Maximum Pressure, Attachment310.0 bar

Maximum Pressure, Swing350.0 bar

Maximum Pressure, Travel310.0 bar

Maximum Swing Oil Flow783.0 L/min

Maximum Total Oil Flow2350.0 L/min

automatic lubrication system

Capacity of Grease Barrel205.0 L

TypeSingle-circuit progressive system with hydraulically driven heavy-duty pump and electronic time control

TypeGrease supplied to swing roller bearing, all pivot points of attachment, and swing gearbox bearing

TypeSystem condition and failures displayed by Board Control System

undercarriage

Bottom Rollers (each side)8

ComponentsForged double-grouser track pads

ComponentsChain links connected by hardened pins and bushings

ComponentsAll running surfaces of sprockets, idlers, rollers and track chain links hardened

ComponentsFully hydraulic self-adjusting track tensioning system with accumulator

ComponentsAutomatic hydraulic retarder valve to prevent overspeed on downhill travel

ComponentsAudible travel alarm

Gradeability of Travel DrivesApproximately 56%

Maximum Tractive Force1066 kN

Parking BrakesWet multiple disc brake, spring loaded/hydraulically released

Support Rollers (each side)2 plus slide

Track Pads (each side)49

Travel Drives (each side)1 planetary transmission with 2 two-stage axial piston motors

Travel Speed: 1st Stage (maximum)1.2 km/h

Travel Speed: 2nd Stage (maximum)2.7 km/h

operator’s cab

ComponentsLarge cab floor window with removable grating for easy cleaning

ComponentsPneumatically cushioned and multi-adjustable operator seat with lumbar support, safety belt, head- and armrests

ComponentsSafety switch in operator’s seat for automatic motion shutdown

ComponentsJoystick integrated in adjustable seat armrest

ComponentsFull sized trainer seat with safety belt and work table

ComponentsAuxiliary fold-away seat with safety belt for 3rd person

ComponentsFOPS (rock guard; approved according to ISO 3449) compliant

ComponentsWindshield with parallel intermittent wiper/washer

ComponentsRoller blinds

ComponentsMachine access via retractable access stairway, stairway angle approximately 45°, hydraulically operated

ComponentsAdditional emergency ladder in close proximity to emergency escape window

Internal Dimensions of Cab: Height2070.0 mm

Internal Dimensions of Cab: Length2230.0 mm

Internal Dimensions of Cab: Width1625.0 mm

New BCS Features:Robust instrument panel including large (254 mm/10 in) color touch screen

New BCS Features:On-screen PDF documentation (e.g. operating instructions, technical handbook, spare parts catalog, electric circuit diagram)

New BCS Features:On-screen troubleshooting assistance

New BCS Features:Graphical data logging

New BCS Features:Fault memory capabilities

New BCS Features:USB, Lan (TCP/IP) and CAN BUS interfaces for data export

New Board Control System (BCS) Features:Electronic monitoring, data logging and diagnostic system for vital signs

service data of engines hydraulic

lube systemOperator’s Cab

operator’s eye level approximate

5.5 mHydraulic Oil Cooling

diameter of fan

1500.0 mmHydraulic Oil Cooling

features

Cooling system fully independent of all main circuits, i.e. controlled cooling capacity available whenever engine is runningHydraulic Oil Cooling

Variable electronically controlled flow of oil through cooler and fan speedHydraulic Oil Cooling

Superior cooling efficiency to ensure optimum oil temperatureHydraulic Oil Cooling

Reversible fan for self cleaning of oil coolerHydraulic Oil Cooling

oil flow of cooling pumps

800.0 L/minSwing System

features

Open swing circuit with auto slow down when joysticks in neutralSwing System

All slew ring raceways and grease tub for internal gearing supplied by automatic, central lubrication systemSwing System

maximum swing speed

4.9 rpmSwing System

parking brake

Wet multiple-disc brake, spring-loaded/hydraulically releasedSwing System

swing drives

2 compact planetary transmissions with axial piston motorsSwing System

swing ring

Triple-race roller bearing with sealed internal gearingEngine

engine model

Cat® C32 ACERT™Engine

gross power – sae j1995

778 kWEngine

net power – sae j1349

778 kWBucket

standard bucket capacity – backhoe heaped 11

12.0 m3Operating Specifications

bucket payload

22 tonnesOperating Specifications

operating weight

224 tonnesWorking Range

maximum digging depth

8.1 mWorking Range

maximum digging reach

15.9 mWorking Range

maximum digging height

13.9 mDigging Forces

maximum tearout force

650 kNDigging Forces

maximum breakout force

730 kN

BENEFITS AND FEATURES

STATE-OF-THE-ART OPERATOR’S ...

Protecting and Supporting Your Most Important Asset: the Operator

LEARN MORE

ADVANCED HYDRAULIC SYSTEM

Reliable Performance from an Efficient, Clean, and Serviceable System

LEARN MORE

CAT BUCKETS AND GROUND ...

Improved Productivity, Operational Efficiency, and Serviceability

LEARN MORE

6020B OPTIONS

- superstructure

Cold-weather package - cab

Redundant HVAC system

Camera system

Cat MineStar ready (Health, Fleet, Terrain, and Detect) - undercarriage

Rough terrain undercarriage protection kit including belly plate and rear plumbing guard - attachment

Work lights on boom - buckets

12.0 m3 (15.7 yd3) backhoe with abrasive wear package for 1.8 t/m3 (3,030 lb/yd3) density

Additional buckets available, based on application, through your local Cat dealer

MOTEUR

Protecting and Supporting Your Most Important Asset: the Operator

BENEFITS AND FEATURES

Optimizing Operator Situational Awareness with Class-leading Cab Visibility

- Direct view of tracks, while seated in the operator’s station, via floor window for safe and easy machine repositioning and underfoot obstacle avoidance.

- Safe machine positioning and truck loading via large windshield and side windows.

- Multiple strategically positioned and high-powered LED lights for maximum illumination of the digging area in dark conditions.

- Heavy-duty wiper ensures good visibility in inclement weather conditions.

Supporting Peak Operator Performance with Enhanced Training Capability

- First in class and patented three-seat design with unobstructed view of digging environment from all seats.

- Elevated observer’s work station, positioned behind the operator seat, provides space for a laptop and great visibility of the operator station and the digging environment.

- Dual in-cab E-stop button easily accessible from both trainer seats and operator station.

Maximizing Operator Alertness and Effectiveness with Leading Comfort Features

- Extremely quiet and fully pressurized cab environment.

- Ergonomic operator seat and controls with armrest adaptable to operator preference.

- 10 inch touch-screen display includes troubleshooting aids and machine documentation.

- Extensive in-cab air distribution via powerful HVAC unit and multiple, optimally positioned, vents.

- Cab module supported with rubber mounts for shock absorption.

- Electro-servo control system ensures no hydraulic lines are present in the cab for a clean, quiet, and odorless environment.

Reliable Performance from an Efficient, Clean, and Serviceable System

BENEFITS AND FEATURES

Fuel Savings as a Result of Best-in-Class Energy Efficiency More efficient hydraulic pump utilization, reduced energy losses, and increased fuel savings are realized with our innovative, patent-pending dedicated pump-flow allocation technology. Additional fuel savings resulting from boom float feature, improving energy efficiency.

Straightforward and Safe System Maintenance Providing easier access for service and de-cluttering of the mainframe, the hydraulic valve block is mounted on the boom.

Consistent Oil Cleanliness for Dependable Hydraulic System Performance The hydraulic system design has been optimized for peak performance and reliability.

- Machine comes equipped with standard high-pressure and return oil filtration.

- A separate kidney loop provides continuous filtration and optimum oil cleanliness at all times, supporting the hydraulic system.

Efficient Oil Cooling for Extended Component Life

BENEFITS AND FEATURES

Protect and Extend the Life of Your Hydraulic Components and Seals Providing an efficient means of cooling, particularly in demanding applications, our unique independent oil cooling system will extend the life of your hydraulic shovel’s components.

More Efficient Oil Cooling Our system is independent of return oil, achieving efficiency through the utilization of dedicated pumps that provide cooling capacity as needed, whether the engine is idling or under load. That means optimum oil temperature is being maintained, even while your operator waits for the next truck to load. Competitive hydraulic shovels only provide cooling when the machine is working and the engine is under load. Additional efficiency is achieved via:

- Variable oil flow

- Variable fan speed

- Auto-reversible fan feature for self-cleaning

Optimal Oil Temperature Maintained Our unique independent oil cooling system ensures that system operating temperatures remain within the optimal operating viscosity range at all times.

Operate with Confidence

BENEFITS AND FEATURES

Enhanced Control Response and Optimized Hydraulic Engine Load Management Help your team meet productivity and performance standards with our intuitive, informative on-board electronics.

Electro-hydraulic Servo Control

- Enhanced Control Response Resulting in Increased Operator Comfort – The system relays actuating signals from the joysticks, delivering load independent and precise machine reactions that reduce operator fatigue.

- Increased Up-time – Up-time is increased as a result of simplified troubleshooting and advanced diagnostic capabilities.

- Clean and Quiet Cab Environment – No hydraulic lines are present in the cab or the cab module, ensuring a clean, odorless arrangement with less noise.

Control and Monitoring Platform (CAMP)

- Reduced Control System Inventory – Streamlined system requires only two controllers for all functions (i.e., drive train and servo).

- Less Fuel Consumption – Both engine and hydraulic pumps work in optimal range of performance during the entire digging cycle, reducing fuel burn.

Designed with Your Safety as Our Top Priority

BENEFITS AND FEATURES

Sharing your commitment to safety, and driven by our commitment to Zero Harm, we work tirelessly to design the safest machines possible to protect your most important asset; your employees. Some examples of the safety-enhancing features of the Cat 6020B Hydraulic Mining Shovel include the following:

Operator Environment

- Optimized operator situational awareness and safe machine positioning/truck-loading via class leading cab visibility.

- Safe training environment facilitated by unobstructed view of digging environment and accessibility of E-stop button from both seat belt equipped trainer seats.

- Enhanced operator safety with fuel and hydraulic oil tanks positioned away from the cab.

- FOPS certified cab with safety glass windshield.

- Cab equipped with emergency hammer for quick escape and ready access to emergency ladder.

Machine Access

- Safe access to power module components from machine platform and counterweight.

- Safe movement about the machine via wide and slip-resistant walkways, limited walkway elevation changes (steps up/down), and minimized trip hazards.

- Quick exit from machine during emergency facilitated by three means of egress.

Sound Suppression

- Excellent power module and cab sound suppression system to protect operators and service personnel.

Electrical System

- Safe electrical maintenance facilitated by lockable battery isolation and starter lockout switch.

Emergency Shut-offs

- Multiple emergency stop buttons strategically located around machine for immediate engine shut-down, including a pull switch accessible from the ground.

Service Friendly for Greater Uptime

BENEFITS AND FEATURES

Designed to Start Producing Almost Immediately Upon Arrival on Site The modular design of the 6020B facilitates quick field assembly. The average assembly time in typical conditions is 14 days; however, similar assembly times were achieved with pilot machines assembled at –30° C (–22° F).

Reduced Downtime Due to Exchangeable Power Module Our exchangeable power module, which contains the most vital machine operating systems, can be quickly removed and replaced with a spare power module to increase machine uptime. This capability also allows for transporting of the power module away from the production area to allow service and repair in a safe, convenient, and clean environment.

Service Friendly, with Unparalleled In-class Component Accessibility The 6020B was designed to be easily serviced and maintained:

- Exceptional component accessibility and weather protection via first-in-class and spacious walk-through power module.

- Superior swing system component accessibility via boom-mounted hydraulic valve block.

- Ground-level accessible service fluid fill points and jump start receptacle.

- Automatic centralized lubrication system.

- 24 hour non-stop machine operation capability.

- Extensive troubleshooting capability via hydraulic service ports.

- Streamlined maintenance and parts availability with integrated Cat components.

Seamless Dealer Support

BENEFITS AND FEATURES

A Single Source for All Service and Maintenance Needs With the use of Cat components throughout, you can rest assured that your local Cat dealer is your most knowledgeable and trusted single source for your 6020B service and maintenance needs. Cat dealer expert technicians have the unique knowledge, experience, training, and tooling necessary to fully support your 6020B hydraulic shovel, no matter the need or where your site is located.

Continued Support throughout the Life of Your 6020B Consistent with any piece of Cat equipment, the 6020B is designed and built to provide maximum productivity, capability and operating economy throughout its working life. To help you meet these performance levels with your 6020B, Cat dealers offer a wide range of service plans that maximize uptime and return on your investment, including:

- Preventative maintenance programs

- Diagnostic programs, such as scheduled oil sampling and technical analysis

- Rebuild and reman options

- Customer support agreements

No One Knows Your 6020B Hydraulic Shovel Better The vast majority of Cat dealers across the globe have supported our line of hydraulic shovels for over a decade, so they are uniquely equipped to optimize the performance of your 6020B with their unmatched Cat hydraulic shovel expertise. This expertise includes a deep understanding of how the 6020B is best applied and utilized in all types of applications, so they can take your site-specific factors into account to help lower your operating and maintenance costs.

Parts Available When You Want Them Receiving 6020B parts from your local Cat dealer is streamlined through the optimized use of Cat components, integrated part numbers, and stocking of parts in local Caterpillar warehouses. Your 6020B will be supported 24 hours a day, 7 days a week, by a worldwide network of parts distribution facilities, dealer service centers, and technical training facilities to keep it up and running at peak performance levels.

Move More Material with Optimal Pass Match Pairings

BENEFITS AND FEATURES

Achieve Targeted Loading/Hauling Production with Perfectly Paired Cat Hydraulic Shovels and Mining Trucks For full truck payloads with minimum loading time, an efficient loading/hauling system begins with an optimized equipment match. Cat hydraulic shovels are matched with Cat mining trucks to maximize volume of material moved at the lowest operating cost per ton. The 6020B was designed to be an optimal pass-match with our popular 777 Series off-highway truck. It is also capable of pairing with the 785 Series mining truck, where applicable.

Simple and Reliable System Supported Seamlessly

BENEFITS AND FEATURES

Simple and Cost-effective Single Engine Concept When we asked you what design features you desired most from a 200 metric ton (220 short ton) size class hydraulic backhoe, a single-engine platform was a top request. We listened by designing the 6020B with a single C32 engine for reliable performance and simple and cost effective service when needed.

Reliable Cat C32 ACERT Tier 2 Engine Delivering durable, reliable power that will keep your 6020B producing, the C32 has proven its ability to perform in harsh mining conditions throughout the world. Offering low operating costs, and supported 24/7 by your local Cat dealer, the C32 will help you achieve your production and profitability targets, reliably.

ACERT Technology The development of ACERT Technology began with the search for a better way to reduce diesel engine emissions, and culminated in a revolutionary engine design breakthrough that burns fuel more precisely than ever before. Lower combustion temperatures reduce emissions and prolong the life of lighter, more power-dense engine platforms. It also varies the injection timing based on factors like engine load and speed for optimum performance under a wide range of operating conditions, including mining.

Worldwide Cat Engine Support Our engines are only as good as the service and support that stand behind them. Highly trained and experienced service technicians at your local Cat dealership are ready with whatever you need, wherever and whenever you need it. They know the Cat C32 engine inside and out, so they can promptly diagnose issues and keep your 6020B running at peak performance.

Evolving Your Mine for Greater Safety and Productivity

BENEFITS AND FEATURES

Helping You Enhance Safety and Productivity through Technology Aimed at enhancing the productivity and profitability of your 6020B hydraulic mining shovel, we currently offer a combination of Cat MineStar System offerings and Cat hydraulic mining shovel technology solutions.

Cat MineStar System Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more. The Cat 6020B is “MineStar ready”, capable of utilizing four of the Cat MineStar System capability sets:

- Health – Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities with a wide range of diagnostic, analytic and reporting tools.

- Fleet – Fleet provides real-time machine tracking, assignment and productivity management, providing a comprehensive overview of all your asset operations from anywhere in the world.

- Terrain – Terrain enables high-precision management of drilling, dragline, grading and loading operations through the use of guidance technology. It increases machine productivity and provides you real-time feedback for improved efficiency.

- Detect – Detect provides equipment operators with enhanced awareness for increased site safety, using a combination of radars, an in-cab display, and multiple cameras.

Hydraulic Shovel Technology Solutions

- Monitoring and Diagnostic System – Enhancing diagnostic capabilities and providing detailed troubleshooting functions, our Board Control System uses sensors throughout the machine to monitor operating data, record faults, and notify the operator audibly and visually. This promotes the earliest possible detection of faults and allows for timely maintenance planning and assistance for speedy repair.

Efficiency Enabling and Simplified Design

BENEFITS AND FEATURES

Enabling the Use of Advanced Hydraulics with an Open-loop Swing Circuit The 6020B includes an open-loop swing circuit that interacts well with its newly designed advanced hydraulics. Utilizing patent-pending dedicated pump flow allocation technology, hydraulic pumps are allocated to individual circuits on demand, allowing all produced oil flow to be translated into cylinder motion, optimizing hydraulic efficiencies and reducing heat generation. To fully leverage the advantages of this innovative technology, the open-loop swing system was incorporated for its use of a common set of pumps to serve all functions and the flexibility it offers for utilization of hydraulic flow.

More Reliable Swing Component Life Extending component life and ultimately improving machine uptime, our swing system includes a triple-race swing roller bearing with internal gearing connected to an automatic lubrication system. For added reliability, all lube lines supplying the swing roller bearing are located inside the superstructure for maximum protection.

Extended Component Life and Superior Serviceability

BENEFITS AND FEATURES

Better wear of undercarriage components

- Even idler slide wear and extended component life result from the floating push tube.

- Low wear drive system via induction hardened and high quantity of sprocket teeth.

- Optional rough terrain undercarriage protection kit available to further protect undercarriage components from harsh ground conditions.

Superior serviceability

- The 6020B’s automatic track tensioning system is a simplified design that requires no manual adjustment.

- Service simplified by externally serviceable break.

Reliable crawler performance

- Exceptional track guidance via standard track guides the entire length of the crawler.

- Usage of a skid plate, instead of a third support roller in the center, helps to prevent build-up of material and jamming of rollers.

- Travel motors and gearboxes are well protected by robust steel covers.

Improved Productivity, Operational Efficiency, and Serviceability

BENEFITS AND FEATURES

Cat Buckets Increase Productivity Cat buckets are designed to match your Cat 6020B mining shovel, providing optimum payload and machine efficiency while protecting your investment. Bucket wear surfaces are armored with replaceable wear materials to extend the life of your bucket. Cat buckets are easy to rebuild, with all parts available through your Cat dealer. Trust Cat to give you long service life without adding excessive weight. Key Features:

- Sized to match the 6020B mining shovel and your application.

- Protected with high abrasion materials matched to the wear characteristics of your application.

- Rebuildable, with all wear components (shown below in red) available as mechanically attached service parts.

MultiPlus Rock Buckets Cat MultiPlus rock buckets are suited for standard rock and soil applications, which constitutes the vast majority of mining and quarry/aggregate applications.

High Abrasion Rock Buckets High abrasion rock buckets are more heavily guarded for use in dense rock and aggressive digging conditions.

G.E.T. Quality and Performance Made Easy Increase your operational efficiency and productivity with hammerless Cat G.E.T. designed specifically for the 6020B hydraulic mining shovel. By designing our own G.E.T., we are able to take a production focus, rather than a component focus, to optimize performance across the entire machine. And like all Cat G.E.T., it is fully supported by your local Cat dealer.

- Simple: No special tools required for Removal

Machine Structures

BENEFITS AND FEATURES

1416578472 Reliable Front Attachment Structures

1416578472 Fully Tested and Validated

1416579064 Sustainability

1416579064 Cat 6020B Sustainability

Large and Robust Structures Designed and Fabricated to Withstand Your Toughest Digging Conditions