320D/D L SERIES 2 HYDRAULIC EXCAVATORS

The 320D/D L Series 2 incorporates innovations to improve your job site efficiency through low owning and operating costs, excellent performance, and high versatility.

SPECIFICATIONS

Engine ModelCat® C7.1

Net Flywheel Power106 kW

Bore105.0 mm

BENEFITS AND FEATURES

operator station

Enhance your comfort, operation, and visibility. The 320D/D L Series 2 allows you to ...

LEARN MORE

engine

A powerful engine with excellent reliability and low fuel consumption delivering more ...

LEARN MORE

hydraulics

Efficient hydraulic system with low effort joysticks provides precise control regardless ...

LEARN MOREengine

Engine ModelCat® C7.1

Net Flywheel Power106 kW

Bore105.0 mm

Stroke135.0 mm

Displacement7.01 L

Engine Power - ISO 14396112.5 kW

Net Power - SAE J1349106 kW

weights

Operating Weight22390.0 kg

Operating Weight (ISO 6016): Long Undercarriage - Maximum Operating Weight22390.0 kg

Operating Weight (ISO 6016): Long Undercarriage - Minimum Operating Weight21680.0 kg

Operating Weight (ISO 6016): Standard Undercarriage - Maximum Operating Weight21690.0 kg

Operating Weight (ISO 6016): Standard Undercarriage - Minimum Operating Weight21040.0 kg

Operating Weight - Long Undercarriage21 680 kg-22 390 kg (47,800 lb-49,360 lb)

Operating Weight - Std. Undercarriage21 040 kg-21 690 kg (46,390 lb-47,820 lb)

drive

Maximum Drawbar Pull205.0 kN

Maximum Travel Speed5.4 km/h

hydraulic system

Pilot System - Maximum Pressure3900.0 kPa

Boom Cylinder - Bore120.0 mm

Boom Cylinder - Stroke1260.0 mm

Stick Cylinder - Bore140.0 mm

Stick Cylinder - Stroke1504.0 mm

B1 Bucket Cylinder - Bore120.0 mm

B1 Bucket Cylinder - Stroke1104.0 mm

Main System - Maximum Flow (Total)404.0 L/min

Maximum Pressure - Equipment35000.0 kPa

Maximum Pressure - Equipment (Lift mode ON)36000.0 kPa

Maximum Pressure - Swing25000.0 kPa

Maximum Pressure - Travel35000.0 kPa

Pilot System - Maximum Flow32.4 L/min (1,977 in3/min)

Swing System - Maximum Flow202.0 L/min

service refill capacities

Fuel Tank Capacity410.0 L

Cooling System25.0 L

Engine Oil22.0 L

Final Drive (each)8.0 L

Hydraulic System (including tank)260.0 L

Hydraulic Oil138.0 L

Swing Drive (each)8.0 L

swing mechanism

Swing Speed10.9 RPM

Swing Torque61.8 kN·m

BENEFITS AND FEATURES

OPERATOR STATION

Enhance your comfort, operation, and visibility. The 320D/D L Series 2 allows you to ...

LEARN MORE

ENGINE

A powerful engine with excellent reliability and low fuel consumption delivering more ...

LEARN MORE

HYDRAULICS

Efficient hydraulic system with low effort joysticks provides precise control regardless ...

LEARN MORE

SERVICE AND MAINTENANCE

Simplified service and maintenance features save you time and money.

LEARN MORE

COMPLETE CUSTOMER SUPPORT

Cat dealer services offer a wide range of personalized solutions.

LEARN MORE

320D/D L Series 2 STANDARD EQUIPMENT

- engine

C7.1 Mechanical engine

Meets U.S. EPA Tier 2, EU Stage II and China Tier 2 emission regulations

4000 m altitude capability

Radial seal air filters (primary and secondary filter)

Glow plugs (for cold weather start)

Automatic engine speed control with one touch low idle

High ambient cooling package 52° C (125° F)

Water separator with water level indicator sensor

Waved fin radiator with space for cleaning

Two speed travel

Electric priming pump

Fuel pressure differential gauge

Power modes (Eco and Standard) - hydraulic system

Regeneration circuits for boom and stick

Auxiliary hydraulic valve

Reverse swing damping valve

Automatic swing parking brake

Boom drift reducing valve

Boom lowering device for back-up

Stick drift reducing valve

Straight travel hydraulic circuit

High performance hydraulic return filters - cab

Pressurized cab

Fully adjustable mechanical suspension seat

Adjustable armrest

Seat belt, retractable (51 mm [2 in] width)

70/30 split front windshield

Laminated upper front windshield and tempered other windows

Sliding upper door window

Openable front windshield with assist device

Pillar mounted upper windshield wiper and washer

Bi-level air conditioner (automatic) with defroster (pressurized function)

Color LCD display with warning, filter/fluid change, and working hour information

Control lever joysticks

Hydraulic activation control lever (lock out for all controls)

Travel control pedals with removable hand levers

Radio mounting (DIN size)

Radio ready

12V - 2× maximum 10A power supply

Two stereo speakers

Beverage holder

Coat hook

Openable roof hatch

Washable floor mat - undercarriage

Idler and center section track guiding guard

Towing eye on base frame

Grease lubricated track - electrical

Batteries (2 × 750 CCA)

115 amp alternator

8 kW starter motor - lights

Left boom working light

Right working light mounted in the storage box

Interior lighting - safety

SECURITY - cat one key security system###door and compartment locks###signalingwarning horn###rearview mirrors###fire wall between engine and pump compartment###emergency engine shutoff switch###rear window emergency exit###battery disconnect switch

COUNTERWEIGHT - 37 mt counterweight

TECHNOLOGY - product link™###cat data link receptacle

320D/D L Series 2 OPTIONS

- engine

Starting kit, cold weather, -32° C (-25.6° F), ether or block heater

Air prefilter - hydraulic system

Auxiliary hydraulics options

Hammer circuit, foot pedal operated

Two way combined circuit, foot pedal operated

Two way combined circuit, joystick operated

Two way combined circuit with medium pressure, joystick operated

Auxiliary hydraulic lines for booms and sticks - undercarriage and guards

600 mm (24") double grouser shoes

600 mm (24") triple grouser shoes

700 mm (28") triple grouser shoes

790 mm (31") triple grouser shoes

Full length track guiding guard (2 pieces)

Guard package includes (HD) bottom, (HD) travel motor, swivel guard - lights

Cab mounted working lights

Right mounted boom light for reach boom - technology

AccuGrade™ Ready Option (ARO) - front linkage

Heavy Duty 5.7 m (18'8") reach boom with left side light: - R2.9B1 (9'6") HD stick - R2.5B1 (8'2") HD stick

Mass boom 5.2 m (17'1") with left side light: - M2.4CB2 (7'11") stick

Super long reach (SLR): - (SLR) Boom 8.85 m (29'0") - (SLR) Stick 6.28 m (20'7") - buckets

General duty buckets from 0.46 m3 (0.60 yd3) to 1.43 m3 (1.87 yd3)

Heavy duty buckets from 1.00 m3 (1.3 yd3) to 1.40 m3 (1.8 yd3)

Severe duty buckets from 1.00 m3 (1.3 yd3) to 1.20 m3 (1.6 yd3)

Extreme duty buckets from 1.00 m3 (1.3 yd3) to 1.20 m3 (1.6 yd3)

Ditch cleaning 0.9 m3 (1.2 yd3) for super long reach arrangement

Ditch cleaning 0.45 m3 (0.6 yd3) for super long reach arrangement

MOTEUR

Enhance your comfort, operation, and visibility. The 320D/D L Series 2 allows you to focus on your job.

BENEFITS AND FEATURES

Operator Station The ergonomically designed operator station is spacious, quiet, and comfortable, assuring high productivity during a long work day. All switches are located in front of the operator for convenient access.

Monitor The monitor is a full-color Liquid Crystal Display (LCD) that has the capability of displaying information in 42 languages.

Joystick Control Low-effort pilot-operated joystick controls are designed to match your natural wrist and arm position for maximum comfort and minimum fatigue.

Seat The suspension seat provides a variety of adjustments to accommodate a wide range of operators. All seats include a reclining back, upper and lower seat slide adjustments, and height and tilt adjustments, to meet operator needs for comfort and productivity.

Console The right and left joystick console can be adjusted to meet individual preferences, improving operator comfort and productivity during the course of a day.

Climate Control Positive filtered ventilation with a pressurized cab is standard. Fresh air or re-circulated air can be selected with a switch on the left console.

Cab Structure and Mounts The cab shell features a thick steel tubing. This improves resistance to fatigue and vibration. The cab is attached to the frame with viscous rubber cab mounts, which dampen vibrations and sound levels while enhancing operator comfort.

Windows To maximize visibility, all glass is affixed directly to the cab, eliminating window frames. The upper front windshield opens, closes, and stores on the roof above the operator with a one-touch action release system.

Wipers Pillar-mounted wipers increase your operator’s viewing area and offer continuous and intermittent modes.

A powerful engine with excellent reliability and low fuel consumption delivering more while boosting your bottom line.

BENEFITS AND FEATURES

The Cat C7.1 engine has been designed to meet U.S. EPA Tier 2, EU Stage II and China Tier 2 emission regulations. The engine is powerful, strong, and durable to meet all of your application needs. An ECO-mode feature helps to reduce fuel consumption by up to 15 percent for fuel-conscious customers. The C7.1 engines incorporate proven, robust components and precision manufacturing you can count on for reliable and efficient operation. This is a proven engine that boasts improved reliability, as it’s less sensitive to low quality fuel and also delivers better fuel consumption.

Automatic Engine Speed Control Automatic engine speed control is activated during no-load or light-load conditions which reduces engine speed to minimize fuel consumption.

Air Cleaner Radial seal air filters feature a double-layered filter core for more efficient filtration and is located in a compartment behind the cab. A warning is displayed on the monitor when dust accumulates above a preset level.

Filtration System The C7.1 engine features an improved filtration system to ensure good reliability to fuel injection system components. Intervals have been extended and the number of filters reduced to maximize your profit potential.

Low Sound, Low Vibration The Cat C7.1 improves operator comfort by reducing sound and vibration.

Efficient hydraulic system with low effort joysticks provides precise control regardless of your application.

BENEFITS AND FEATURES

Hydraulic System Hydraulic system pressure is 35 000 kPa (5,076 psi) with 202 L/min (53.36 gal/min) flow from each of the two hydraulic pumps for increased digging performance and productivity.

Pilot System An independent pilot pump enables smooth precise control for the front linkage, swing, and travel operations.

Component Layout The 320D/D L Series 2 hydraulic system and component locations have been designed to provide a high level of system efficiency. The main pumps, control valves, and hydraulic tank are located close together to allow for shorter tubes and lines between components, which reduce friction loss and pressure drops.

Hydraulic Cross-Sensing System The hydraulic cross-sensing system utilizes each of two hydraulic pumps to 100 percent of engine power under all operating conditions. This improves productivity with faster implement speeds and quicker, stronger pivot turns.

Auxiliary Hydraulic Valve Control circuits are available as attachments to improve versatility. They allow operation of high- and medium-pressure tools such as shears, grapples, hammers, pulverizers, multi-processors, and vibratory plate compactors.

Boom and Stick Regeneration Circuit Boom and stick regeneration circuits save energy during boom-down and stick-in operation which increases efficiency, reduces cycle times and pressure loss for higher productivity, lower operating costs, and increased fuel efficiency.

Hydraulic Cylinder Snubbers Snubbers are located at the rod-end of the boom cylinders and both ends of the stick cylinders to cushion shocks while reducing sound levels and extending component life.

Hydraulic Activation Control Lever With the hydraulic activation lever in the neutral position all front linkage, swing, and travel functions are isolated.

Strong and durable, all you expect from Cat excavators.

BENEFITS AND FEATURES

Carbody Design and Track Roller Frames The X-shaped, box-section carbody provides excellent resistance to torsional bending. Robot-welded track roller frames are press-formed, pentagonal units to deliver exceptional strength and service life.

Main Frame The upper frame is designed using inverse “T” shaped beams made out of high-tensile-strength steel providing excellent durability whatever your application. The 320D/D L Series 2 incorporates a one-piece upper frame table which improves strength and reliability. Both the boom tower and the main frame are constructed of solid plates and the areas adjacent to the boom foot are reinforced, adding to overall durability.

Lower Structure The 320D/D L Series 2 carbody features a box section “X” structure which is designed with the carbody welded close to the ends of the track roller frame. As a result, overall rigidity is high and resistance to torsional rigidity between the track roller frames and the carbody is also high. The standard undercarriage is well suited for applications that require frequent repositioning of the machine, restricted work space, or uneven rocky terrain. The long (L) undercarriage maximizes stability and lift capacity. This long, wide, and sturdy undercarriage offers a very stable work platform.

Rollers and Idlers Sealed and lubricated track rollers, carrier rollers, and idlers provide excellent service life to keep your machine in the field and working longer.

Undercarriage The 320D/D L Series 2 uses a grease-lubricated type track link with grease being sealed between the pin and the bushing. These seals deliver longer wear life by preventing dirt and debris from entering into the space between the pin and the bushing. The master link incorporates a split type pin which helps make routine service and maintenance quick and easy.

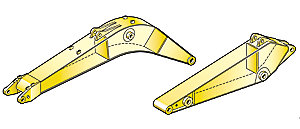

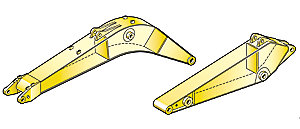

Reliable, durable, and versatile to meet all your application needs.

BENEFITS AND FEATURES

Cat front linkages are designed for maximum versatility, productivity, and high efficiency whatever the application.

Heavy Duty Front Linkage The 5.7 m (18'8") heavy duty (HD) reach boom is reinforced to be used in the severest applications and provide maximum digging capability. They are made of high-tensile-strength steel using a large box-section design with interior baffle plates and an additional bottom guard for long life and durability. The HD reach boom has two stick options available to meet all your application requirements. The 2.9 m (9'6") heavy duty (HD) stick is the most versatile option and a very good fit for truck loading and trenching applications where you need additional working range. The 2.5 m (8'2") heavy duty (HD) stick is ideally suited to applications requiring larger bucket sizes. It maximizes digging forces and enables you to get your jobs completed faster.

Mass Boom Front Linkage The mass excavation (ME) front linkage is designed to maximize machine performance through superior digging forces and a larger bucket capacity. The 5.2 m (17'1") mass excavation boom is reinforced with a geometry designed to maximize machine productivity. It also incorporates a large cross-section and internal baffle plates for long life and durability. The 2.4 m (7'11") mass excavation stick was designed mainly for large earth moving and is made of high-tensile-strength steel in a box section to make it strong and durable.

Super Long Reach This super long reach option provides up to 15.2 m (49'10") of reach and is designed for light-duty applications requiring an extra-large working envelope.

Simplified service and maintenance features save you time and money.

BENEFITS AND FEATURES

Ground-Level Service The design and layout of the 320D/D L Series 2 was made with the service technician in mind. Most service locations are easily accessible at ground level to allow service and maintenance to get completed quickly and efficiently.

Air Filter Compartment The air filters feature a double-element construction for superior cleaning efficiency. When the air filter plugs, a warning is displayed on the cab monitor. Maintenance free batteries are standard along with a battery disconnect switch.

Pump Compartment A service door on the right side of the upper structure allows ground-level access to the hydraulic pumps, hydraulic filters, engine oil filter, and fuel filters.

Radiator Compartment The left rear service door allows easy access to the engine radiator, hydraulic oil cooler, air-to-air aftercooler, and AC condenser. A reserve tank and drain cock are attached to the radiator for ground level maintenance.

Greasing Points A concentrated remote greasing block on the boom allows the greasing of hard-to-reach locations. A remote mounted greasing point on the swing bearing allows ease of service.

Fan Guard The engine radiator fan is enclosed by a steel guard that provides maximum protection when carrying out routine service and maintenance.

Anti-Skid Plate Anti-skid plating covers the entire upper structure and storage box to prevent slipping during maintenance. Safety is further enhanced with the addition of countersunk bolts to reduce trip hazards.

Diagnostics and Monitoring The 320D/D L Series 2 is equipped with Scheduled Oil Sampling (S∙O∙SSM) ports for the hydraulic system, engine oil, and coolant. Standard hydraulic test ports enable a service technician to quickly and easily fault find in the event of service issue.

Cat dealer services offer a wide range of personalized solutions.

BENEFITS AND FEATURES

Product Support Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. You can also save money with our line of remanufactured components.

Machine Selection Your Cat dealers can provide specific recommendations with detailed comparisons of the Cat machines you are considering before you buy. This ensures you get the right size machine and appropriate work tools to meet all of your application needs.

Maintenance Services Repair option programs guarantee the cost of repairs up front. Condition monitoring services and diagnostic programs such as scheduled oil sampling, coolant sampling, and technical analysis help you avoid unscheduled repairs.

Customer Support Agreements Cat dealers offer a variety of product support agreements which can be tailored to meet your specific needs. These plans can cover the entire machine - including attachments - to help protect your investment.

Replacement Repair, rebuild, or replace? Your Cat dealers can help you evaluate the costs involved so you can make the right choice.

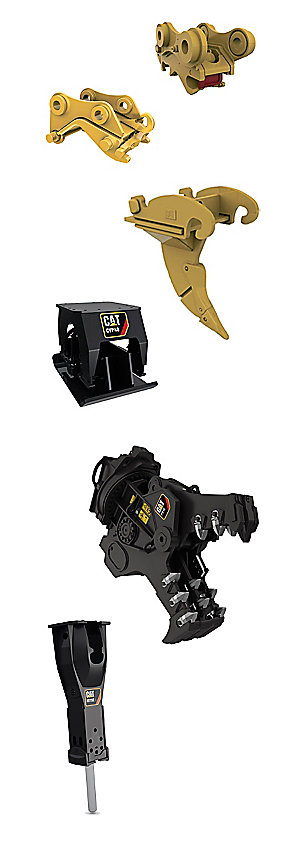

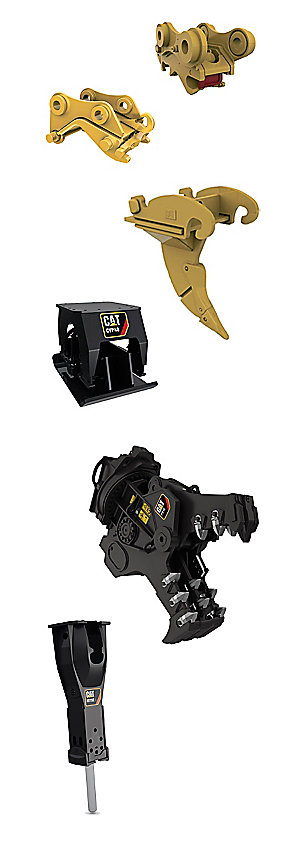

Dig, hammer, rip, and cut with confidence.

BENEFITS AND FEATURES

Each Cat work tool is designed to optimize the versatility and performance of your machine. An extensive range of buckets, compactors, grapples, multi-processors, rippers, crushers, pulverizers, hammers, and shears is available for your 320D/D L Series 2.

Buckets Cat buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine to ensure optimal performance and fuel efficiency.

Utility Buckets (UD) These buckets are for digging in low-impact, low-abrasive material such as dirt, loam, and clay.

General Duty Buckets (GD) These buckets are designed for digging in low-impact, moderately abrasive materials such as dirt, loam, gravel, and clay.

Heavy Duty Buckets (HD) HD buckets are a good starting point when application conditions vary. Especially when conditions include mixed dirt, clay, sand, and gravel.

Severe Duty Buckets (SD) These buckets are best suited to highly abrasive applications such as shot rock, sand stone, and granite.

Extreme Duty Buckets (XD) These buckets are for very high abrasion conditions including high quartzite granite. Example: Digging conditions where tip life is less than or equal to 200 hours with Extra Duty tips.

Couplers Quick couplers allow one person to change work tools in seconds for maximum performance and flexibility on a job site. One machine can move rapidly from task to task, and a fleet of similarly equipped machines can share a common work tool inventory.

Center-Lock™ Pin Grabber Coupler Center-Lock is the pin grabber style coupler and features a patent-pending locking system. A highly visible secondary lock clearly shows the operator when the coupler is engaged or disengaged from the bucket or work tool.

E Series Hammers E series hammers bring together customer expectations of performance, quality, and serviceability along with Caterpillar manufacturing and logistics experience. E series hammers are quiet, and noise suppression is valuable in urban and restricted work areas.

Pin-on Rippers, Rip and Load Package Constructed from high-strength steels and built to last, Cat rippers endure in the toughest conditions. The box-section structure is reinforced for maximum rigidity, transmitting the full machine power to the material being ripped. Rippers feature a replaceable wear tip, and most models also come equipped with a replaceable shank protector.

Grapples Cat grapples replace the bucket on Cat excavators, converting them to the ideal machine for handling loose material, sorting trash, and demolition site cleanup. An array of styles and sizes are available to match excavators to the task at hand.

Multi-Processors Multi-processors do the work of many types of demolition tools by use of interchangeable jaw sets. Changing jaws allows a single unit to crush, pulverize, and perform a variety of specialized cutting tasks such as cutting steel rebar and tanks.

Shear Cat shears are designed for Cat machines - taking full advantage of the hydraulic flows and pressures to enhance productivity without compromising safety or causing premature wear of the shear and carrier.

Pulverizer The excavator mounted mechanical pulverizer is a cost-effective tool for recycling demolished concrete debris. The bucket cylinder on the excavator powers the mechanical pulverizer. This eliminates the need for a dedicated cylinder and associated hydraulics and additional installation cost.

Vibratory Plate Compactor Compactors enhance the versatility of your excavator and makes compacting faster, more efficient, and cost-effective. Cat compactors are the superior choice for any job site’s compaction tasks.

Crusher The hydraulic concrete crusher has taken modern demolition technology a step further. It is well suited for concrete demolition in residential areas. The hydraulic concrete crusher combines several concrete demolition operations in one piece of equipment:

- breaking out concrete from fixed structures

- pulverizing concrete

- cutting reinforcement rods and small steel profiles