326D2 L HYDRAULIC EXCAVATOR

The 326D2 L OEM incorporates innovations to improve your job site efficiency through low owning and operating costs, excellent performance, and high versatility. Fuel consumption is reduced by 13% compared to 324D with meeting Tier 3 regulations on High Power mode.

SPECIFICATIONS

Engine ModelCat® C7.1

TypeDirect Injection

Engine Gross Power (ISO 14396)147 kW

BENEFITS AND FEATURES

key features

A world class design combining excellent performance with low fuel consumption and top ...

LEARN MORE

operator station

Ergonomically designed to keep you comfortable and productive all day long.

LEARN MOREengine

Engine ModelCat® C7.1

TypeDirect Injection

Engine Gross Power (ISO 14396)147 kW

Net Flywheel Power144 kW

Engine Net Power (SAE J1349/ISO 9249)144 kW

Displacement7.01 L

Bore105 mm

Stroke135 mm

Rated Speed (engine)1900 rpm

Hi-Idle Speed1700 rpm

Low-Idle Speed950 rpm

Maximum Torque (torque peak) @ 1,400 rpm900 N·m

Maximum Altitude (without derate)3000 m

Maximum Altitude (with derate)5000 m

weights

Maximum Frontless Machine Weight21090 kg

Maximum Operating Weight*26375 kg

*NoteDependent on application, Review

swing mechanism

Swing Speed9.6 rpm

Swing Torque73.4 kN·m

drive

Travel Speed – High Load5.8 km/h

Travel Speed – Low Load5.4 km/h

Drawbar Pull227 kN

service refill capacities

Fuel Tank Capacity520 L

Cooling System31 L

Engine Oil22 L

Swing Drive10 L

Final Drive (each)6 L

Hydraulic System (including tank)285 L

Hydraulic Tank257 L

hydraulic system

Main System – Maximum Flow at travel H/L (1,800 rpm)247 × 2 L/min (494 total) [65.2 × 2 gal/min (130.4 total)]

Main System – Maximum Flow at travel L/L (1,700 rpm)233 × 2 L/min (466 total) [61.6 × 2 gal/min (123.2 total)]

Main System – Maximum Flow at operation (1,700 rpm)233 × 2 L/min (466 total) [61.6 × 2 gal/min (123.2 total)]

Swing System – Maximum Flow233 L/min

Maximum Pressure – Equipment35 MPa

Maximum Pressure – Travel35 MPa

Maximum Pressure – Swing24.5 MPa

Pilot System – Maximum Flow23.4 L/min

Pilot System – Maximum Pressure3920 kPa

exterior sound

Spectator Sound Power LevelLabeled spectator sound power level measured according to test procedures and conditions specified in 2005/88/EC is 103 dB(A).

standards

BrakesSAE J1026/APR90

Cab/FOGSSAE J1356 FEB88; ISO 10262

Cab/ROPSISO 12117-2:2008

engine

NoteThe C7.1 engine meets U.S. EPA Tier 3 and EU Stage III emission regulations.

BENEFITS AND FEATURES

KEY FEATURES

A world class design combining excellent performance with low fuel consumption and top ...

LEARN MORE

OPERATOR STATION

Ergonomically designed to keep you comfortable and productive all day long.

LEARN MORE

SERVICE AND MAINTENANCE

Simplified service and maintenance features save you time and money.

LEARN MORE

326D2 L OEM STANDARD EQUIPMENT

- engine

C7.1 electronic control engine

Meets U.S. EPA Tier 3 and EU Stage III emission regulations

3000 m (9,842 ft) altitude capability without derating (Maximum 5000 m (16,404 ft) with derate from 3000 m [9,842 ft])

Air prefilter

Radial seal air filters (primary and secondary filter)

Glow plugs

Automatic engine speed control with one touch low idle

High ambient cooling package 52° C (126° F)

Starting kit, cold weather, Water separator with water level indicator sensor

Radiator and oil cooler side by side with enough space for cleaning

Two speed travel

Electric fuel (Priming) pump

Power modes (Eco and High Power)

Variable fan with viscous clutch

New fuel filtration system (primary ×1, secondary and third filter ×1)

B20 biodiesel fuel capability

Air-to-air-aftercooler - hydraulic system

Automatic swing parking brake

High performance hydraulic return filters

Hydraulic main pump

Fine swing control

Cat bio-oil capability

Capability of installing additional valves, pumps, circuits

Stick drift reducing valve*

Boom drift reducing valve*

Auxiliary hydraulic valve*

Reverse swing damping valve* - cab

Pressurized cab

Mechanical or air suspension seat

Positive filtered ventilation

Adjustable armrest

Seat belt, retractable

70/30 split front windshield

Laminated upper front windshield and tempered other windows

Sliding upper door window

Openable front windshield with assist device

Openable roof hatch

Removable lower windshield, within cab storage bracket

Pillar mounted upper windshield wiper and washer

Bi-level air conditioner (automatic) with defroster (pressurized function)

Full color and full graphic LCD display with warning, filter/fluid change, and working hour information

Seat integrated control lever joystick

Neutral lever (lock out) for all controls

Travel control pedals with removable hand levers

Two stereo speakers

Radio mounting

Beverage holder

Coat hook

Interior lighting

Ashtray and lighter

Rear window, emergency exit

Capability to install two additional pedals

Bolt-on FOGS (Falling Objects Guarding System) capability - undercarriage

Idler and center section track guiding guards

Towing eyes on base frame

Grease lubricated track GLT2, resin - electrical

Batteries (2 – 900 CCA)

Capability to connect a beacon - lights

Working light, storage box mounted

Interior lighting - safety and security

Cat one key security system

Door and compartment locks

Signaling/warning horn

Rearview mirrors

Rearview camera ready

Fire wall between engine and pump compartment

Emergency engine shutoff switch

Rear window, emergency exit

Battery disconnect switch

Cap locks on fuel and hydraulic tanks

Lockable tool box - counterweight

4750 kg (10,470 lb) counterweight - technology

Product Link

326D2 L OEM OPTIONS

- hydraulic system

Tool control system

Hammer circuit, foot pedal operated

Two way combined circuit, joystick modulation operated

Two way combined circuit with medium pressure, joystick modulation operated - cab

12V-10A power supply

Sun screen

Radio 24V

Travel alarm

Falling Objects Guarding System (FOGS)

Rearview camera and mirrors - undercarriage and guards

Long undercarriage: – 600 mm (24") double grouser shoes – 600 mm (24") triple grouser shoes – 790 mm (31") triple grouser shoes

Segmented track guiding guard (two pieces)

Swing frame with bumper capability: – (HD) bottom – (HD) travel motor – Swivel guard - lights

Cab mounted working lights - technology

AccuGrade

MOTEUR

A world class design combining excellent performance with low fuel consumption and top reliability.

BENEFITS AND FEATURES

Performance/Efficiency

- Fuel consumption is reduced by 13% compared to 324D with meeting U.S. EPA Tier 3 and EU Stage III emission regulations

- Isochronous engine speed control

- Electrical Fuel Priming Pump replaces hand priming pump

- Pressure sensor measures Negative Flow Control pressure to improve the hydraulic efficiency

Ease of Operation

- Ergonomically designed cab with easy to operate controls

- Multiple seat and joystick adjustment options enhance comfort

- Excellent work site visibility from the cab enhances productivity

- Optimized low effort joystick controls reduce operator fatigue

- New monitor with 40% larger viewing screen, 4× higher resolution and 42 language options available

Reliability/Serviceability

- The strong and durable carbody has been designed to work in the toughest operating conditions

- All electrical wires are colored, numbered and protected with thick navy braiding for ease of identification and long life

- Heavy duty stress-relieved booms and heavy duty sticks are standard

- Grease and Lubricated Tracks (GLT) provides longer service life

- New fuel injection system for improved reliability

Reduced Costs

- Service intervals 500 hours

- There are two different power modes; High Horse Power (HHP) and ECO Mode. 13% fuel consumption reduction vs. 324D is with HHP mode.

Technology

- Integrated Cat technology solutions increase production and minimize operating costs

- Product Link™ reports key information from the machine to any location

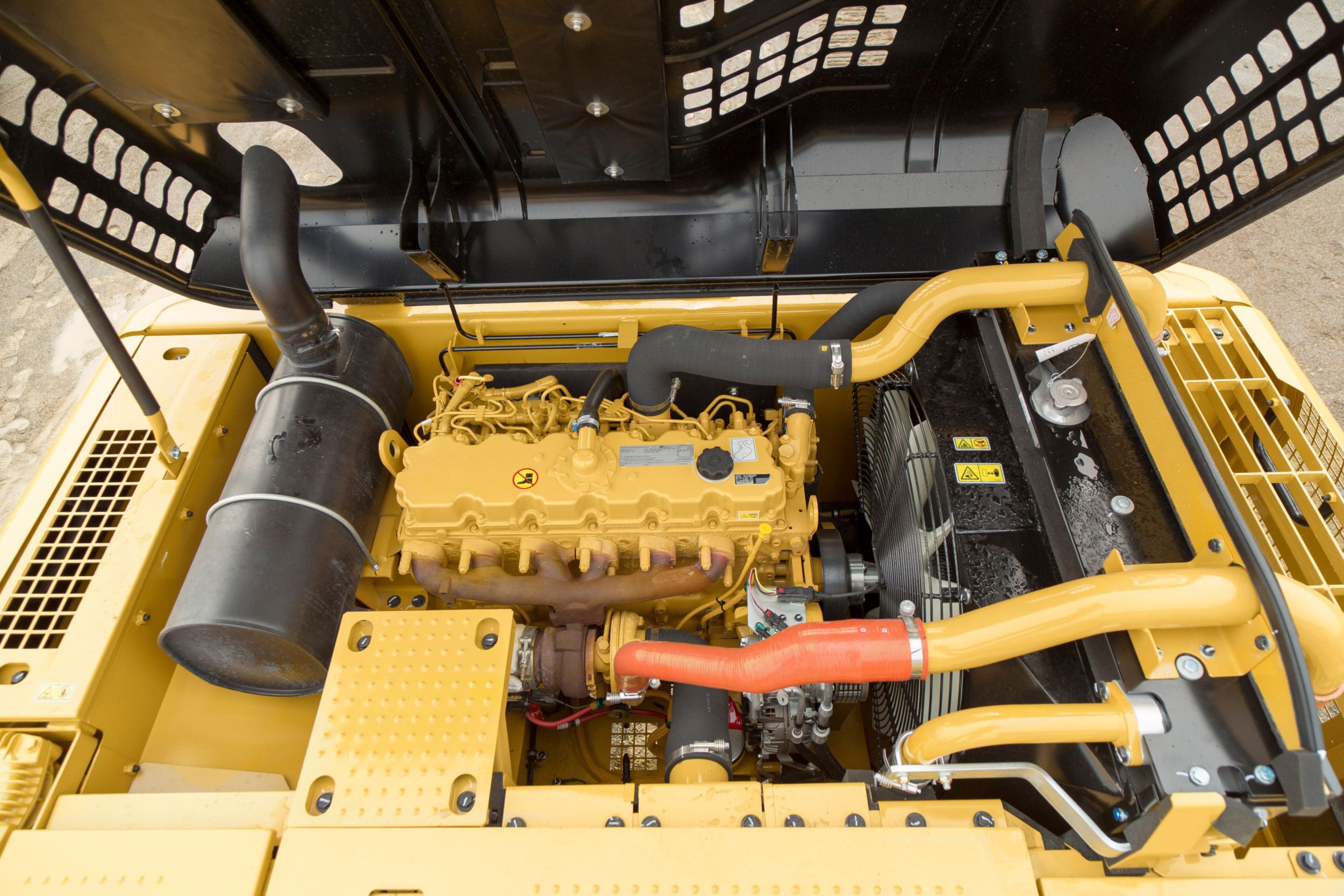

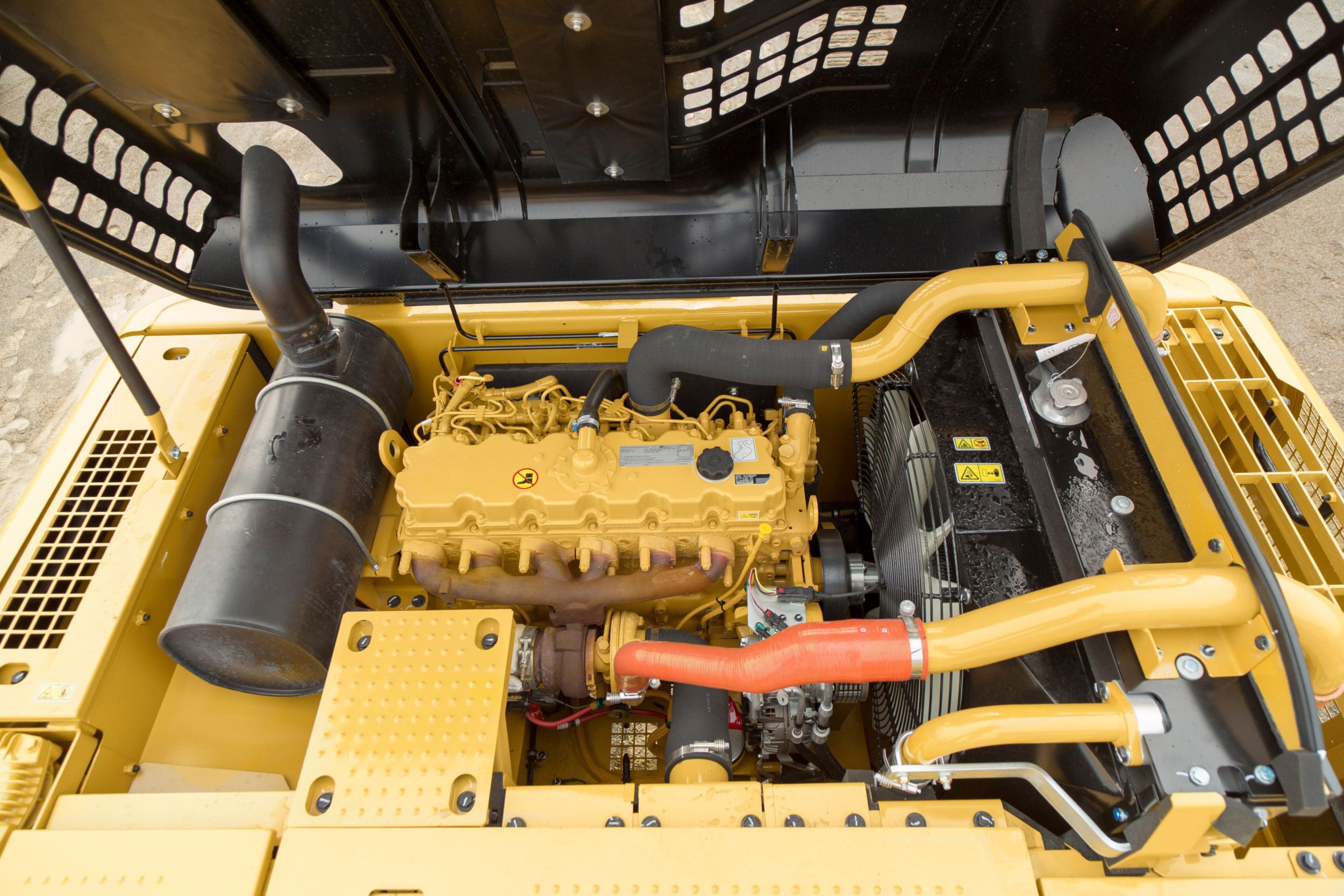

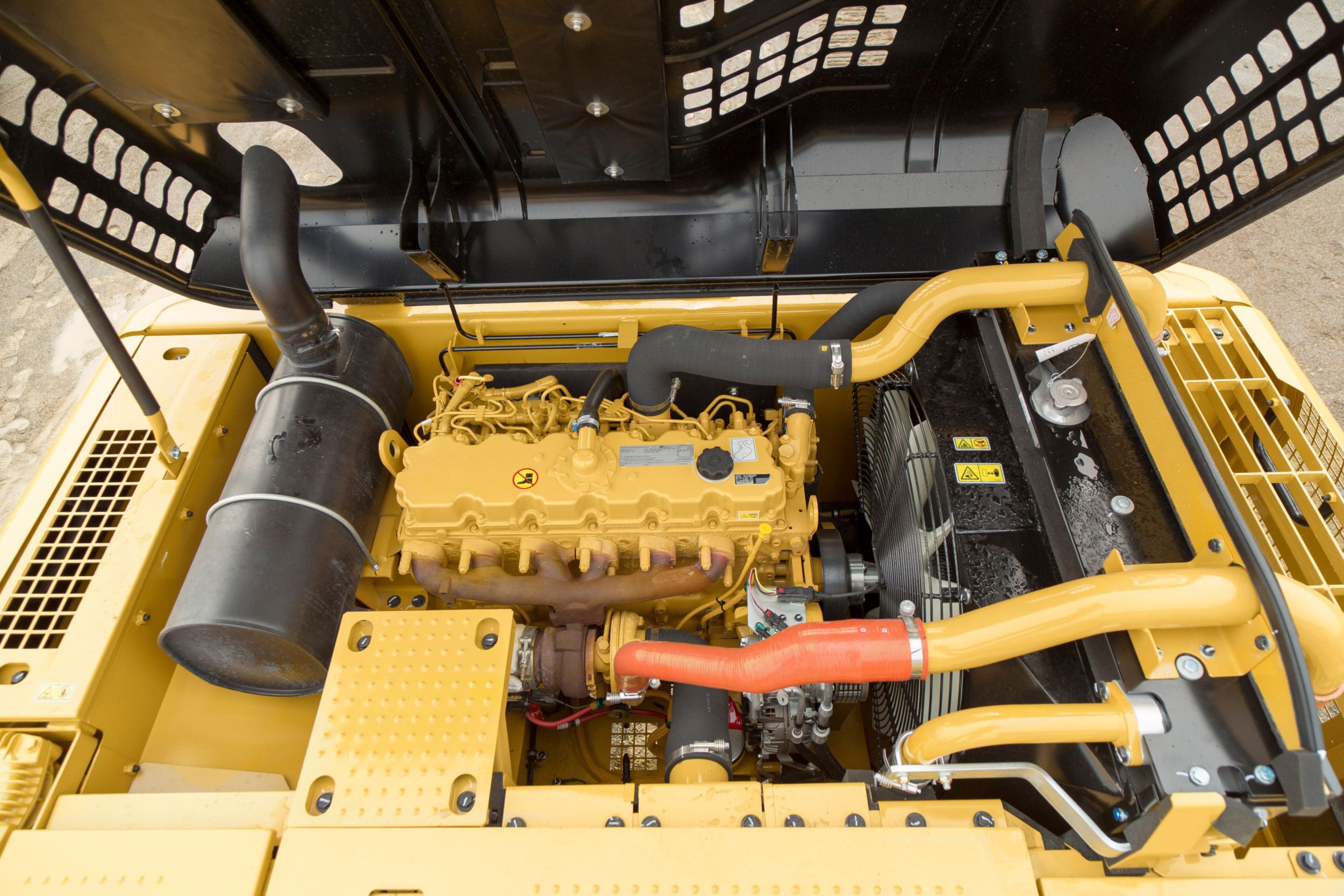

Built for power, reliability and economy.

BENEFITS AND FEATURES

Reliable Cat C7.1 Engine The Cat C7.1 engine has been designed to meet U.S. EPA Tier 3 and EU Stage III emission regulations. The C7.1 engine incorporates proven, robust components and precision manufacturing you can count on for reliable and efficient operation. This is a proven engine that boasts improved reliability, as it’s less sensitive to low quality fuel and also delivers reduced fuel consumption. 13% fuel consumption reduction vs. 324D is with HHP mode.

Automatic Engine Control Automatic engine control is activated during no-load or light-load conditions which reduces engine speed to minimize fuel consumption.

Air Cleaner The radially sealed air filter features a double-layered filter core for more efficient filtration and is located in a compartment behind the cab. A warning is displayed on the monitor when dust accumulates above a preset level.

Filtration System The C7.1 engine features an improved filtration system to ensure reliability to the fuel injection system components. The primary filter and the secondary twin filters improve filtration efficiency and machine robustness.

Ergonomically designed to keep you comfortable and productive all day long.

BENEFITS AND FEATURES

ROPS Certified Operator Station The 326D2 L features a ROPS (Roll Over Protective Structure) compliant cab structure as standard which meets OSHA and MSHA sound requirements. This design also allows for a Falling Object Guard System (FOGS) or front windshield guard to be bolted directly to the cab, either at the factory or in the field, enabling the machine to meet all job site requirements.

- More glass versus previous non-ROPS cab to improve visibility

- More interior head room space

- Improved cab pressurization

- ROPS cab air filter accessible at ground level

Monitor The new monitor on the 326D2 L features a 40 percent larger screen with four times increased resolution display. The LCD monitor is equipped with a warning lamp and buzzer for critical engine oil pressure, coolant temperature and oil temperature. Programmable in up to 42 languages to meet today’s diverse workforce, the monitor clearly displays critical information needed to operate efficiently and effectively. Filters and fluid change intervals are available in the main menu which also projects the image from the optional rearview camera, further enhancing your job site safety and productivity.

Seat The suspension seat provides a variety of adjustments to accommodate a wide range of operators. All seats include a reclining back, upper and lower seat slide adjustments, and height and tilt adjustments.

Controls Operators can adjust the right and left joysticks for individual preferences, helping them become more comfortable, more productive, and more alert. Low‑effort pilot-operated joystick controls are designed to match your natural wrist and arm position for maximum comfort and minimum fatigue.

Climate Control The 326D2 L offers positive filtered ventilation with a pressurized cab. Fresh air or recirculated air can be selected which makes working in the heat and cold much more pleasant.

Cab Structure and Mounts The cab shell is attached to the frame with viscous rubber cab mounts which dampen vibrations and sound levels while enhancing operator comfort. Thick steel tubing along the bottom perimeter of the cab improves resistance to fatigue and vibration.

Cat hydraulics deliver power and precise control to keep material moving.

BENEFITS AND FEATURES

Hydraulic System Hydraulic system pressure from the two-hydraulic pump system delivers the best in class digging performance and productivity.

Pilot System An independent pilot pump enables smooth, precise control for the front linkage, swing, and travel operations.

Hydraulic Activation Control Lever With the hydraulic activation lever in the neutral position, all front linkage, swing, and travel functions are isolated.

Component Layout The hydraulic system and component locations have been designed to provide a high level of system efficiency. The main pumps, control valves, and hydraulic tank are located close together to allow for shorter tubes and lines between components, reducing friction loss and pressure drops.

Hydraulic Cross-Sensing System The hydraulic cross-sensing system utilizes each of two hydraulic pumps to 100 percent of engine power under all operating conditions. This improves productivity with faster implement speeds and quicker, stronger pivot turns.

Auxiliary Hydraulic Valve Control circuits are available as attachments to improve versatility. They allow operation of high- and medium-pressure tools such as shears, grapples, hammers, pulverizers, multi-processors, and vibratory plate compactors.

Strong and durable, all you expect from Cat excavators.

BENEFITS AND FEATURES

Robotic Welding Up to 95% of the structural welds on a Cat Excavator are completed by robots. Robotic welds achieve over three times the penetration of manual welds.

Carbody Design and Track Roller Frames X-shaped, box-section carbody provides excellent resistance to torsional bending. Robot-welded track roller frames are press-formed, pentagonal units which deliver exceptional strength and service life.

Rollers and Idlers Sealed and lubricated track rollers, carrier rollers, and idlers provide excellent service life to keep the machine in the field longer.

Long Undercarriage The long undercarriage (L) maximizes stability and lift capacity. This long, wide and sturdy undercarriage offers a very stable work platform.

Frame The upper frame includes reinforced mountings to support the ROPS cab, the lower frame is reinforced to increase component durability.

Tracks The 326D2 L track links are assembled and sealed with grease to decrease internal bushing wear, reduce travel noise and extend service life lowering operating costs.

Counterweight The 4.8 mt (5.2 t) standard counterweight makes a better choice for heavy lifting with long undercarriage. Counterweights are bolted directly to the main frame for extra rigidity.

Simplified service and maintenance features save you time and money.

BENEFITS AND FEATURES

Ground-Level Service The design and layout of the 326D2 L was made with the service technician in mind. Most service locations are easily accessible at ground level to allow service and maintenance to get completed quickly and efficiently.

Air Filter Compartment The left side service compartment features the battery disconnect switch, electrical circuit breakers, air conditioning condenser core. The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Pump Compartment A service door on the right side of the upper structure allows ground‑level access to the pump, pilot filter, and water separator with primary fuel filter.

Radiator Compartment The left rear service door allows easy access to the engine radiator, hydraulic oil cooler, air-to-air-aftercooler, second and third fuel filters, and fuel cooler. A reserve tank and drain cock are attached to the radiator for simplified maintenance.

Greasing Points Conveniently located grease blocks help you get lube in hard-to-reach places, making routine boom, stick, and bucket linkage maintenance quick and easy.

Fan Guard The engine radiator fan is completely enclosed by fine wire mesh, reducing the risk of an accident.

Anti-Skid Plate Anti-skid plate with countersunk bolts reduce trip hazards which covers top of storage box and upper structure to prevent accidents during maintenance.

Diagnostics and Monitoring The 326D2 L is equipped with S∙O∙SSM ports to easily sample hydraulic and engine oil quality. Test ports are also conveniently located so you can test coolant and hydraulic pressure.

Monitor, manage, and enhance your job site operations.

BENEFITS AND FEATURES

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you’ll get more information and insight into your equipment and operations than ever before. Cat Connect technologies offers improvements in these key areas: Equipment Management – increase uptime and reduce operating costs. Productivity – monitor production and manage job site efficiency. Safety – enhance job site awareness to keep your people and equipment safe.

LINK Technologies LINK technologies like Product Link wirelessly connect you to your equipment, giving you valuable insight into how your machine or fleet is performing. Track location, hours, fuel usage, idle time, and event codes through the online VisionLink® interface so you can make timely, fact-based decisions that can boost job site efficiency and productivity, and lower operating costs.

DETECT Technologies DETECT technologies like the rear-vision camera enhance operator awareness by expanding your view of the environment around working equipment. Work with greater confidence and at peak potential while keeping people and assets safe.

Cat dealer services help you operate longer with lower costs.

BENEFITS AND FEATURES

Product Support You can maximize your machines’ uptime with the Cat worldwide dealer network. You can also decrease your repair costs by utilizing Cat remanufactured components while contributing to sustainable development.

Machine Selection What are the job requirements and machine attachments? What production do you need? Your Cat dealer can provide recommendations to help you make the right machine configuration.

Purchase You can ensure lower owning and operating costs by utilizing unique Cat dealer services and financing options.

Customer Support Agreements Cat dealers offer a variety of customer support agreements and work with you to develop a plan to meet your specific needs. These plans can cover the entire machine, including attachments, to help protect your investment.

Operation You can boost your profits by improving your operators’ techniques. Your Cat dealer has videos, literature, and other ideas to help increase productivity. Caterpillar also offers simulators and certified operator training to help maximize the return on your investment.

Replacement Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the best choice for your business.