PM102 TRACK UNDERCARRIAGE COLD PLANER

The new PM102 with a track undercarriage combines enhanced production capabilities, optimized performance and simplified service to complete tough milling applications with productive results. The Cat® C7 Engine with ACERT Technology provides ample power while meeting U.S. EPA Tier 3 and European EU Stage IIIa compliancy. Designed for high production and long life, the PM102 rotor has quick release conical tool holders for quick and easy tool replacement. And the conveyor can be folded to reduce machine dimensions during transport.

SPECIFICATIONS

Cutting Width1000.0 mm

Maximum Cutting Depth305.0 mm

Number of Cutting Tools97

BENEFITS AND FEATURES

cat® c7 engine with acert ...

The Cat® C7 Engine with ACERT Technology combines proven systems with innovative new ...

LEARN MORE

propel system

Hydrostatic drive with hydraulic flow provided by a variable displacement axial piston ...

LEARN MORE

rotor assembly

Cutting Width1000.0 mm

Maximum Cutting Depth305.0 mm

Number of Cutting Tools97

engine

Engine ModelC7 with ACERT

Gross Power168.0 kW

service refill capacities

Fuel Tank Capacity400.0 L

Water Spray System1060.0 L

weights

Operating Weight with full water tank17600.0 kg

Shipping Weight with empty water tank17100.0 kg

conveyor system

Collecting Conveyor Speed252.0 m/min

Collecting Conveyor Width550.0 mm

Discharge Conveyor Length6.3 m

Discharge Conveyor Width600.0 mm

Discharge Conveyor Maximum Speed252.0 m/min

Discharge Conveyor Swing (from center)41.0 Degrees

dimensions

Operating Length (conveyor up)10.7 m

Operating Width1.98 m

Maximum Operating Height3.4 m

Minimum Operating Height2.38 m

Maximum Truck Clearance4.8 m

Shipping Length - base machine5.33 m

Shipping Maximum Height3.1 m

Shipping Width2.5 m

Shipping Length - with conveyor folded8.5 m

operating specifications

Inside Turning Radius3.45 m

Maximum Travel Speed4.1 km/h

Operating Speed27.0 m/min

BENEFITS AND FEATURES

CAT® C7 ENGINE WITH ACERT ...

The Cat® C7 Engine with ACERT Technology combines proven systems with innovative new ...

LEARN MORE

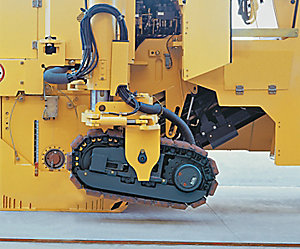

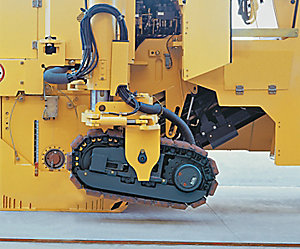

PROPEL SYSTEM

Hydrostatic drive with hydraulic flow provided by a variable displacement axial piston ...

LEARN MORE

ROTOR

Designed for high production and long service life. Quick release conical tool holders ...

LEARN MORE

PRIMARY COLLECTING CONVEYOR

The collecting conveyor belt efficiently clears out the cutter box fast. Water spray ...

LEARN MORE

FOLDING FRONT LOADING CONVEYOR

High capacity and versatility add to increased job site productivity. Conveyor can be ...

LEARN MORE

OPERATOR’S STATION

Designed for efficiency, productivity and simple operation. Easy to reach controls ...

LEARN MORE

FLUSH CUTTING FEATURE

Full flush cutting operation with hydraulic control of the right rear leg, allows the ...

LEARN MORE

AUTOMATIC GRADE AND SLOPE ...

The optional grade controls provide precise control of rotor to a preset cutting depth. ...

LEARN MORE

RELIABILITY AND SERVICEABILITY

Reliability and serviceability are integrated into every Cat machine. These important ...

LEARN MOREPM102 - Track OPTIONS

- automatic grade and slope system

- hydraulically operated canopy

- high pressure washdown system

- water tank high capacity refilling pump

- roading light package

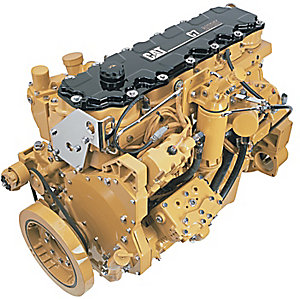

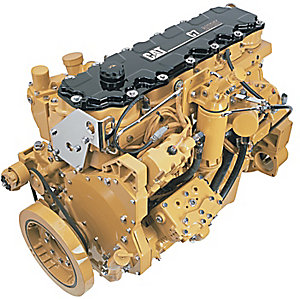

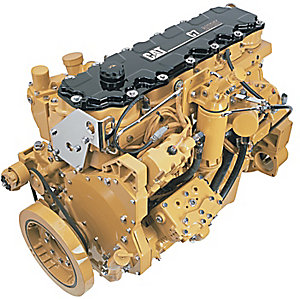

MOTEUR

The Cat® C7 Engine with ACERT Technology combines proven systems with innovative new technologies to precisely deliver fuel to the combustion chamber. Powerful and efficient, the C7 is US Tier 3 and EU Stage IIIa emissions compliant.

BENEFITS AND FEATURES

Cat Diesel Engine The engine offers outstanding value by combining industry leading electronic capabilities, performance and reliability with optimum fuel economy.

Optimized Power Curve Engine power curve is optimized for milling applications providing optimum power while keeping the engine operating at peak efficiency.

Turbocharged and Air-to-air Aftercooling (ATAAC) High horsepower with increased response time is assured while keeping exhaust temperatures low and in concert with the tight tolerance combustion chamber components, maximizing fuel efficiency and minimizing emissions.

Hydraulic Electronic Unit Injection This feature provides reduced engine noise, improved fuel economy, faster hot and/or cold starts and better high altitude performance.

Hydrostatic drive with hydraulic flow provided by a variable displacement axial piston pump. Dual displacement drive motors on each track provides balanced tractive effort.

BENEFITS AND FEATURES

Load Control System (Anti-Stall) The electronically controlled system matches propel speed to load on engine for maximum production.

Two Speed Ranges The machine operates at either maximum torque throughout the entire milling speed range or at a faster travel speed for moving around the job site.

Positive Traction Control (Flow Divider) Equal hydraulic oil flow to each drive motor increases tractive effort in hard cutting applications. The positive traction control is actuated from the operator’s console.

Polyurethane Track Pads Track pads in polyurethane provide long service life and positive traction on all pavement surfaces.

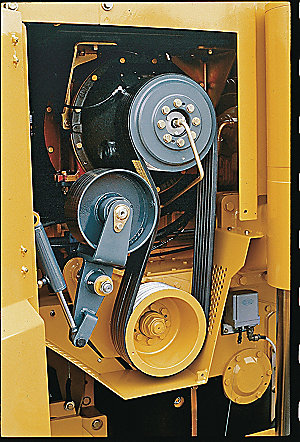

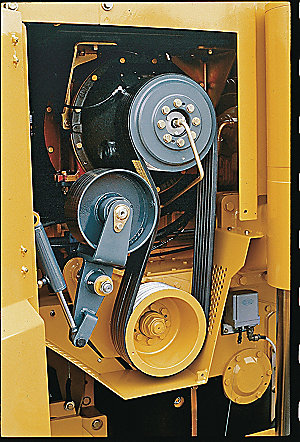

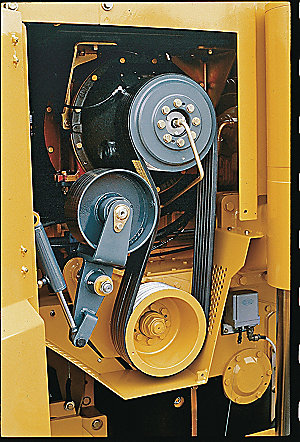

Delivers maximum available horsepower to each cutting tool.

BENEFITS AND FEATURES

Mechanical Dry Clutch The rotor drive consists of trapezoid pulleys, molded high-strength belt and a hydrauliccoupling dry clutch. The field-proven drive system delivers reliability and long service life.

Drive Train Protection A drive train protection device protects rotor drive system, rotor and tools by instantly disengaging rotor drive whenever an abrupt drop in rotor rpm occurs.

Two Cutting Speeds Upper and lower sheaves are easily interchangeable for maximum torque with the toughest materials and different material sizing requirements.

Molded Six-Rib High Tensile Belt High tensile belt provides efficient transmission and long service life.

Automatic Belt Tension Adjustment The hydraulically powered automatic drive belt tensioner prevents rotor drive belt slippage and reduces maintenance.

Designed for high production and long service life. Quick release conical tool holders for quick and easy tool replacement.

BENEFITS AND FEATURES

98 Carbide-Tipped Tools Tools are mounted in durable three-piece, quick release patented tool holders and arranged in a triple wrap flighting pattern for maximum breakout force.

Quick Release Conical Tool Holders A tapered fit maintains tightness in holder base. Fast and effortless tool removal is provided by the quick release conical tool holder tool removing system.

Large Replaceable Carbide Faced Loading Paddles Loading paddles effectively move milled material onto collecting conveyor resulting in higher production and less wear on inside of rotor chamber and cutting tools.

Optimum Tool Spacing Triple-tree tool placement on rotor ends provides optimum tool spacing to clean up loose material and reduces wear on drum when maneuvering in the cut.

The collecting conveyor belt efficiently clears out the cutter box fast. Water spray system for lubrication, cooling and dust reduction.

BENEFITS AND FEATURES

Optimum Material Sizing and Gradation The hydraulically operated anti-slab device prevents slabbing of the road surface, protects the collecting conveyor and ensures an optimum discharge opening to the rotor chamber.

Maximum Efficiency The collecting conveyor's width measures in at 550 mm (21.6") and is driven by a high torque hydraulic motor for maximum efficiency.

Variable Belt Speed The collecting conveyor features variable belt speed for optimum production in all applications. Reversible belt rotation control is also provided.

Optimum Dust Reduction Standard pressurized water spray lubricates and controls dust on collecting belt. Water spray nozzles are easily removed for inspection and replacement without the need for tools.

High capacity and versatility add to increased job site productivity. Conveyor can be folded to reduce machine dimensions during transport.

BENEFITS AND FEATURES

Folding Conveyor Machine transportation is made easier by the folding front conveyor that reduces the machine dimensions.

Hydrualically Controlled Height Adjustment The upper conveyor's width measures in at 600 mm (23.6") and its height adjustment is hydraulically controlled while two cylinders provide a 41 degree swing to the left and right.

Variable Loading Belt Speed and Reversible Rotation The front loading conveyor also includes variable belt speed and reversible belt rotation control. The loading belt speed is infinitely variable and provides optimum discharge capability for uniformly loading the haul truck.

Simplified Conveyor Removal Quick-fitting hydraulics and mechanical conveyor components allow the front conveyor to be easily detached from the machine.

Designed for efficiency, productivity and simple operation. Easy to reach controls minimize operator fatigue.

BENEFITS AND FEATURES

Ergonomic Operator's Station The full width operator’s station provides a view of the front loading conveyor and side plates for precise and rapid positioning.

Suspension Seat Durable suspension seat with armrest provides optimum operator comfort.

Warning Horns and Shut Down Buttons Located on the operator’s station and at ground level control stations.

Hydrualically Operated Canopy Option Full width canopy with two extending side wings and front windshield and rear window provides optimum operator comfort and protection. Canopy can be hydraulically lowered during transportation.

Operating Controls The distribution and clear instrumentation layout on the front and side control consoles have been designed to ensure minimum operator effort and maximum automation. All gauges and displays are easily visible even in direct sunlight.

Graphic Disply A large display, easily visible in direct sunlight, provides operating parameters for machine and engine diagnostics. The display presents a single interface for service diagnostics and calibration.

Computerized Monitoring System (CMS) The system constantly monitors system pressures and engine condition with multiple modes of operation. Alerts the operator if a problem does occur with three levels of event information.

Standby Control A single switch control allows the operator to engage or disengage main operating functions including propel, water spray system, leveling system and conveyor rotation for maximum automation.

Full flush cutting operation with hydraulic control of the right rear leg, allows the PM102 to be used up close to a curb, wall or guard rail.

BENEFITS AND FEATURES

Flush Cutting The right rear leg can be swung in within the machine’s cutting width for full flush cutting applications. With the right rear leg swung in, the machine can cut close to a wall, barrier or other vertical obstruction.

Exclusive Caterpillar Single-Peice Swing-Arm Design The swing-in arm mechanism ensures increased rigidity eliminating excessive wear for increased component life.

Automatic Control The rear leg swing-in system is automatic and controlled from the operator’s station. The operator is not required to leave the seat while positioning the right rear leg within the machine’s cutting width.

Optimum machine handling for precise control and production.

BENEFITS AND FEATURES

Precise Control A microprocessor electronically controls the steering angle of the right rear track. The rear track steering angle is automatically adjusted in relation to the position of the front tracks.

Enhanced Steering Ability The machine's rear track steering feature facilitates operation in confined areas and ensures a close cut around cul-de-sacs or turns. The right rear track steers in both positions, whether positioned within or outside the cutting width.

The optional grade controls provide precise control of rotor to a preset cutting depth. System can be configured to control grade or cross slope.

BENEFITS AND FEATURES

Contacting Wire Rope Grade Sensors Wire rope grade sensor measures side plate movement that enables the entire length of the side plate to become an averaging device for extremely accurate grade matching. Cross slope sensor adds to system versatility.

Leveling Control Boxes Two control boxes located at the operator’s station allow manual or automatic leveling adjustment. Constant read-out for rotor depth and cross slope are displayed on each control box and is easily visible even in direct sunlight or low light conditions.

Reliability and serviceability are integrated into every Cat machine. These important features keep your machine investment profitable.

BENEFITS AND FEATURES

Large Service Doors Large service doors provide access to engine and hydraulic components. Engine side covers swing wide to allow ground level access to engine. Rear cover swings up for access to radiator and oil cooler.

Hydrualic Rotor Service Door The rotor service door opens wide for easy access to rotor for inspection and tool maintenance.

Electronic Control Module (ECM) The ECM monitors machine systems and provides self-diagnostics for operator or service personnel.

All-Weather Connectors Nylon braided wrap ensure electrical system integrity.

Visual Indicators Visual indicators allow easy check of water spray tank level and hydraulic oil tank level.