AP1000E PAVER

Based upon the industry-proven reputation of the Cat® AP1000D Asphalt Pavers, the AP1000E establishes new industry standards for productivity and reliability. The AP1000E Paver offers cleaner power, fuel efficiency and high performance in a mobile and versatile platform.

SPECIFICATIONS

Maximum Operating Weight19508.0 kg

Standard Paving Width3.05-5.94 m (10-19.5 ft)

Hopper Capacity7.1 m3

BENEFITS AND FEATURES

cat c71 engine with acert™ ...

ACERT Technology utilizes a series of Caterpillar engineered innovations that provide ...

LEARN MORE

fumes management system

The ventilation system draws fumes from the conveyor tunnel as well as the auger chamber ...

LEARN MORE

high capacity cooling system

The high capacity cooling system allows the fan to run slower, reducing power demand ...

LEARN MOREweights

Maximum Operating Weight19508.0 kg

operating specifications

Standard Paving Width3.05-5.94 m (10-19.5 ft)

Hopper Capacity7.1 m3

Inside Turning Radius0.5 m

Maximum Paving Speed with Tamper Bar Screed25.0 m/min

Maximum Paving Speed with Vibratory Screed61.0 m/min

Maximum Travel Speed20.0 km/h

Paving Width Maximum8.0 m

Paving Width Minimum2.44 m

Truck Dump Height585.0 mm

Truck Entry Width3.52 m

engine

Gross Power168.0 kW

Engine ModelCat C7.1 with ACERT

dimensions

Length with Push Roller and Largest Screed6.63 m

Maximum Height3.72 m

Tractor Operating Width3.6 m

Transport Height2.87 m

Transport Width, Hoppers Raised, Screed End Gates Attached3.24 m

Transport Width, Hoppers Raised, Screed End Gates Removed3.0 m

service refill capacities

Fuel Tank Capacity348.0 L

BENEFITS AND FEATURES

CAT C7.1 ENGINE WITH ACERT™ ...

ACERT Technology utilizes a series of Caterpillar engineered innovations that provide ...

LEARN MORE

FUMES MANAGEMENT SYSTEM

The ventilation system draws fumes from the conveyor tunnel as well as the auger chamber ...

LEARN MORE

HIGH CAPACITY COOLING SYSTEM

The high capacity cooling system allows the fan to run slower, reducing power demand ...

LEARN MORE

DUAL OPERATOR STATIONS

The dual operator stations provide complete control and good visibility from either side ...

LEARN MORE

WHEEL UNDERCARRIAGE SYSTEM

The wheel undercarriage system provides excellent mobility and maneuverability along with ...

LEARN MORE

OPERATOR CONSOLES

The operator consoles are designed for productivity and accessibility. All gauges and ...

LEARN MORE

EXCLUSIVE MATERIAL DELIVERY ...

Productivity and quality enhancements are built-in features.

LEARN MORE

GATELESS FEEDERS

Variable speed feeders precisely control mix delivery while reducing wear and segregation.

LEARN MORE

GENERATOR SYSTEM (OPTIONAL)

The high capacity, integrated generator ensures peak performance and high reliability.

LEARN MORE

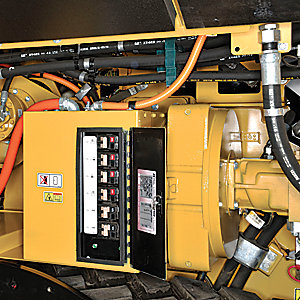

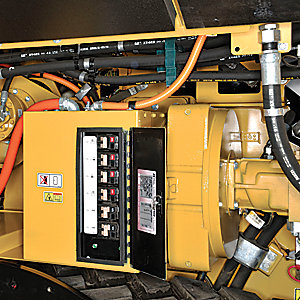

AUXILIARY POWER PANEL ...

The auxiliary power panel provides efficient power for night-time lighting and other job ...

LEARN MORE

ELECTRIC HEAT SCREEDS

The AS3301C and AS2301C vibratory screeds, as well as the AS4251C and AS4252C tamper bar ...

LEARN MORE

SERVICEABILITY

Simplified service means more paving time and less maintenance time. Large swing-open ...

LEARN MORE

CATERPILLAR CUSTOMER SUPPORT ...

Caterpillar offers “Solutions and Services” and around-the-clock support that meets ...

LEARN MOREAP1000E OPTIONS

- tractor options

Auger and Mainframe Extensions

Oscillating Push Rollers

Truck Hitch

Generator

Auxiliary Power Panel

Ventilation System

Decelerator Pedals

Sonic Feeder Sensor or Proportional Paddle Sensor

Steering Guide

Warning Beacon

Umbrella

Uptime Kit

Washdown System

Front Wheel Assist - controls and grade references

Automatic Grade and Slope Control

Non-Contacting Sonic Grade Sensor

Contacting Grade Sensor

Outboard Leveler, 9.15 m (30') and 12.2 m (40')

Inboard Leveler

Mobile Stringline

Fore ‘N Aft Leveler

Sonic Averaging Beam

Rigid Ski, 9.15 m (30') and 12.2 m (40') - screed choices

Extend-A-Mat™ 10-20B (electric or diesel)

Extend-A-Mat 10-20WB (diesel only)

AS2301 (electric or diesel)

MOTEUR

ACERT Technology utilizes a series of Caterpillar engineered innovations that provide advanced electronic control, precise fuel delivery and refined air management.

BENEFITS AND FEATURES

Cat C7.1 Engine with ACERT Technology The C7.1 engine provides 168 kW (225 hp) at 2200 rpm with a torque of 872 N-m. The combination of large displacement and high torque allow the AP1000E to perform under the toughest conditions.

Cat C6.6 Engine with ACERT Technology The C6.6 engine provides 168 kW (225 hp) at 2200 rpm with a torque of 1028 N-m. The combination of large displacement and high torque allow the AP1000E to perform under the toughest conditions.

Emissions Reduction Technology The Cat C7.1 engine is equipped with a Diesel Particulate Filter (DPF) that traps soot from the exhaust stream. The soot is removed through a process called regeneration, while the ash remains in the filter and must be removed at a required service interval of 5000 hours. The C7.1 engine utilizes two types of regeneration, passive and active.

Regeneration Regeneration occurs during normal idle periods. The C7.1 utilizes two types of regeneration: active and passive. Neither active nor passive regeneration require operator intervention.

Meets U.S. EPA Tier 4 Interim and E.U. Stage IIIB Emissions Standards Reduces oxides of nitrogen by 50 percent from Tier 3/Stage IIIA levels. Reduces particulate matter by 90 percent from Tier 3/Stage IIIA levels. Ultra Low Sulfur Diesel (ULSD) fuel is required. Engine oil must meet Caterpillar ECF-3, API CJ-4/ACEA E9 specifications.

Service, Maintenance and Repair Easier service, maintenance and repair is accomplished by monitoring key functions and logging critical indicators. Advanced electronic diagnostic capabilities are possible using Cat Electronic Technician.

Eco-mode increases fuel efficiency Once activated, Eco-mode reduces engine rpm from 2200 rpm to 1650 rpm, which is suitable for most normal paving applications. The reduction of engine rpm during operation will reduce fuel burn compared with normal engine rpm. If an application demands more power, Eco-mode can be deactivated to return to 2200 rpm.

The ventilation system draws fumes from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

BENEFITS AND FEATURES

The high capacity cooling system allows the fan to run slower, reducing power demand while extending component life.

BENEFITS AND FEATURES

Variable Speed Fan The variable speed fan is electronically controlled and hydraulically driven providing on-demand cooling, reduced engine power demand and quiet operation.

The dual operator stations provide complete control and good visibility from either side of the operating platform.

BENEFITS AND FEATURES

Dual Operator Stations The dual operator stations incorporate fully equipped consoles with adjustable suspension seats, armrests and retractable seat belts.

Operator Visibility The dual operator stations can be positioned in one of four different locations to provide optimum visibility. The stations can extend beyond the machine frame for good visibility when joint matching or while paving other applications where precise control is required.

The wheel undercarriage system provides excellent mobility and maneuverability along with a smooth ride for optimum performance.

BENEFITS AND FEATURES

Excellent Mobility The sharp turning radius and high speeds allow the paver to move quickly around the job site.

Three Propel Modes Pave, travel and maneuver modes provide good control and versatility. The maneuver mode provides less than a 0.5 m (1.5') inside turning radius for excellent maneuverability in tight quarters.

Large Drive Tires The 18.00 R25 sand-rib drive tires provide good tractive effort and a smooth ride.

Large Steering Tires The 16" x 22", solid rubber steering tires provide maximum ground contact and smooth operation.

Front Suspension Four, front solid rubber steering wheels are mounted on pairs of oscillating bogies, providing a smooth ride.

Steering Assist Steering assist feature improves maneuverability and enhances component life by adjusting the drive speed of one side of the propel system according to the steering angle of the front wheels which allows the machine to turn while maintaining the same speed.

Front Wheel Assist (Optional) The front wheel assist feature provides power to the rear bogey wheels for additional tractive effort.

Long Wheel Base The long wheel base provides good tractive effort and stability on soft base materials.

The operator consoles are designed for productivity and accessibility. All gauges and displays are grouped for convenient and simple operation.

BENEFITS AND FEATURES

Operator Consoles Each operator’s station includes ground speed indicators, material handling controls, propel controls and screed extender controls. The controls for each station are in the same relative position providing easy control from either console.

Speed Control Dial A speed control dial located on each operator station allows the operator to set a maximum travel speed which is important for producing a smooth, high-quality mat.

Machine Controller The machine controller integrates performance functions and allows the feeder and auger speeds to be set independently which extends component life.

Advisor Display The Advisor display provides visual references, self diagnostics, and planning tools that keep the operator informed for better overall job site performance.

Productivity and quality enhancements are built-in features.

BENEFITS AND FEATURES

Mix Delivery The AP1000E provides precise mix delivery with minimal operator monitoring through the most advanced material handling system.

Feeders Controlled Independently Left and right feeders in addition to the left and right augers are controlled independently. The ability to control these four components separately, through a machine controller, eliminates the need for feeder gates.

Mix Delivery Control In order to control mix delivery, the operator sets a speed rate for each feeder that will maintain the desired mix level in the left and right auger chambers. Once the feeder speeds are set, the ratio of feeder speed to the maximum auger speed is automatically maintained by the machine controller, even though the propel rate may change as the job progresses.

Ratio Control This ratio control capability is particularly helpful when paving wider on one side of the machine than on the other. Each feeder can be set at a specified speed to deliver the proper amount of mix that is needed.

Increased live tunnel area provides easy servicing.

BENEFITS AND FEATURES

Variable speed feeders precisely control mix delivery while reducing wear and segregation.

BENEFITS AND FEATURES

Gateless Feeders Run Full of Mix The gateless feeders on the AP1000E always run full of mix regardless of the speed required to fill the auger chamber. This is typically a slower speed than would be experienced with a paver utilizing feeder gates to control mix delivery rates. By not always having to run at full speed, feeder component wear is significantly reduced.

Changes in Feeder Speed When changes in feeder speed are required, delivery of mix to the augers is immediate. This is in contrast to pavers with gates, where any delivery rate change is delayed for the length of time it takes to clear the tunnel of mix from the previous gate setting.

Running at Lower Speeds Running at slower speeds can also help reduce the opportunity for segregation, especially when working with larger stone mixes that have more of a tendency to segregate.

Tunnel construction improves mix flow.

BENEFITS AND FEATURES

Provides mat consistency while minimizing segregation.

BENEFITS AND FEATURES

The high capacity, integrated generator ensures peak performance and high reliability.

BENEFITS AND FEATURES

Single Control Switch A single switch on the tractor’s operating console activates the generator. The generator operates at 1800 rpm and includes GFCI protection.

The auxiliary power panel provides efficient power for night-time lighting and other job site power needs.

BENEFITS AND FEATURES

The AS3301C and AS2301C vibratory screeds, as well as the AS4251C and AS4252C tamper bar screeds feature multi-zone electric heating, easy-to-use touch pad interface, and even-heat distribution.

BENEFITS AND FEATURES

Operator-Friendly Environment The electric screed plate heating system eliminates the use of diesel fuel burners, creating a user-friendly environment.

Fast Warm-Up Time The electric screed provides a warm-up time in 30 minutes or less to 122° C (220° F) when ambient temperatures are at or above 22° C (40° F).

Proven and Reliable Whether you are paving interstates, highways, residential streets or commercial sites, the electric screed heat system performs under the toughest conditions.

Simple Operation The screed control panel incorporates touch-pad technology with high intensity LEDs that promote simplified use and diagnostic capability with minimal operator training.

Multi-Zone Heating Elements The heating elements are mounted to the screed plates in a multi-zone configuration to provide even heat distribution.

Thermostatically Controlled The screed plates incorporate thermostatically controlled temperature sensors in each screed section including the extenders. The temperature sensors provide inputs to the screed controller.

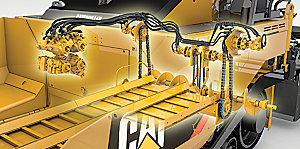

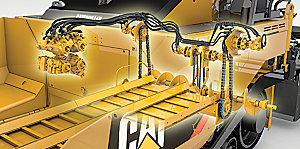

Simplified service means more paving time and less maintenance time. Large swing-open doors and panels provide convenient access to service areas. Transverse engine mounting provides ground-level access to hydraulic pumps and the engine cooling system. Color-coded and numbered wiring simplifies troubleshooting of the electrical systems. The standard 500-hour engine oil change interval increases machine up-time.

BENEFITS AND FEATURES

Advisor Display The Advisor display provides visual references, self diagnostics, and planning tools that keep the operator informed for better overall job site performance.

Large Access Doors and Panels Preventative maintenance points can be accessed through the large swing-open access doors and panels.

Remote Lubrication Points Grease fittings are grouped to provide quick, routine service of bearings.

Quick-Connect Sampling Ports The quick-connect ports simplify retrieval of critical fluids for diagnosis.

Color-Coded and Numbered Electrical System Troubleshooting is efficient and simplified with the color-coded and numbered electrical system.

Electronic Control Modules (ECMs) The multiple ECMs communicate with the Advisor display. The display lists service codes, providing quick reference. The ECMs are compatible with Cat Electronic Technician and easily connect to a laptop computer for fast technical support.

The closed-loop system automatically compensates for component wear, hydraulic oil temperature and oil viscosity changes to ensure complete, low-effort, operator control.

BENEFITS AND FEATURES

Propulsion Control The machine controller provides accurate control of steering and propulsion systems and ensures straight-line tracking.

Caterpillar offers “Solutions and Services” and around-the-clock support that meets your everyday needs.

BENEFITS AND FEATURES

Project Consulting Project consulting provides a service for improving smoothness, density, and productivity.

Technical Training Technical training offers in-depth hands-on training to mechanics at Caterpillar training centers or customer locations.

Application Training Paving Operations Training (POT) is a hands-on methodical approach to the process of paving. The process of “Paving by the Numbers” guides the crew when setting up to pull off the joint.

Machine Support Parts for asphalt pavers and screeds are available at the Cat Dealer parts counter. Cat Dealers also utilize a world-wide computer network to find in-stock parts to minimize machine downtime.