740B BARE CHASSIS ARTICULATED TRUCK

The new Cat® 740B with 39.5 tonnes (43.5 tons) rated payload offers proven reliability and durability, high productivity, superior operator comfort and lower operating costs. The spacious two-person cab with forward facing passenger seat and off road oil/nitrogen front suspension cylinders keep the operator comfortable through out the working day. The true “on-the-go” Automatic Traction Control (ATC) automatically modulates the correct level of Inter-Axle and Cross-Axle differential lock engagement which will improve cycle times and productivity. No operator interaction. Strong, durable Cat ACERT™ engines with the Tier 4 Interim/EU Stage IIIB exhaust emission solution and electronically controlled smooth shifting transmissions deliver high productivity with low fuel consumption. There are significant changes/improvements to the engine/transmission software that result in smoother gear changes.

SPECIFICATIONS

Engine ModelCat® C15 ACERT™

Gross Power - SAE J1995365.0 kW

Net Power - SAE J1349354.0 kW

BENEFITS AND FEATURES

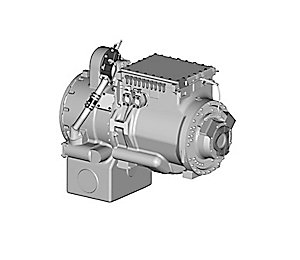

engine

Engine ModelCat® C15 ACERT™

Gross Power - SAE J1995365.0 kW

Net Power - SAE J1349354.0 kW

Bore137.0 mm

Stroke171.5 mm

Displacement15.2 L

Engine Model Tier 4 Interim/EU Stage IIIBCat® C15 ACERT™

Net Power - ISO 14396361.0 kW

weights

Rated Payload39.5 tonnes

body capacities

Heaped SAE 2:124.0 m3

Struck18.5 m3

Tailgate Heaped SAE 2:125.5 m3

Tailgate Struck19.5 m3

transmission

Forward 18.9 km/h

Forward 212.1 km/h

Forward 316.4 km/h

Forward 422.0 km/h

Forward 530.0 km/h

Forward 640.0 km/h

Forward 754.7 km/h

Reverse 18.4 km/h

Reverse 211.6 km/h

operating weights

Front Axle - Empty20746.0 kg

Center Axle - Empty7196.0 kg

Rear Axle - Empty6466.0 kg

Total - Empty34408.0 kg

Front Axle - Rated Load5211.0 kg

Center Axle - Rated Load17186.0 kg

Rear Axle - Rated Load17186.0 kg

Total - Rated Load39582.0 kg

Front Axle - Loaded25956.0 kg

Center Axle - Loaded24382.0 kg

Rear Axle - Loaded23652.0 kg

Total - Loaded73990.0 kg

body plate thickness

Front8.0 mm

Scow16.0 mm

Side12.0 mm

Base16.0 mm

service refill capacities

Fuel Tank565.0 L

Cooling System80.0 L

Hydraulic System322.0 L

Engine Crankcase34.0 L

Transmission72.0 L

Final Drives/Differential230.0 L

Output Transfer Gear Box18.0 L

sound levels

Interior Cab79.0 dB(A)

body hoist

Raise Time12.0 Seconds

Lower Time7.0 Seconds

standards

BrakesISO 3450 - 1996

Cab/FOPSISO 3449 Level II - 2005

Cab/ROPSISO 3471 - 2008

SteeringISO 5010 - 2007

steering

Lock to Lock4.6 seconds @ 60 rpm

turning circle

NoteDimensions are for machines equipped with 29.5R25 tires.

Turning Dimensions - Aisle width5694.0 mm

Turning Dimensions - Clearance radius8595.0 mm

Turning Dimensions - Inside radius4101.0 mm

Turning Dimensions - SAE turning radius8138.0 mm

Turning Dimensions - Steer angle - left/right45.0 Degrees

BENEFITS AND FEATURES

DURABILITY AND RELIABILITY

High machine availability maximizes productivity and lowers costs.

LEARN MORE

740B Bare Chassis STANDARD EQUIPMENT

- air conditioning with r134a refrigerant

- air vents adjustable

- automatic traction control atc

- auto shift sevenspeed forward and twospeed reverse transmission

- back up alarm

- body adapted for exhaust heat

- cat® c15 engine with acert™ technology

- cat clean emission module cem an exhaust aftertreatment package

- color multipurpose display cmpd incorporating the cycle counter and rearview camera screen

- cdradio heavy duty ready

- differentials standard with automatic clutched crossaxle and interaxle differential locks for all axles

- electrical system 24 volt 5a 24 to 12volt converter

- electro hydraulic hoist control

- ether starting aid

- glass windows laminated and tinted front

- glass windows toughened and tinted sides and rear

- guards rear window radiator crankcase and axle

- headlights four

- heater and defroster with fourspeed fan

- horn electric

- lights cab interior front side rear two reversingworking lights two stoptail lights side width marker front and rear direction indicators

- mirrors main and auxiliary left and right

- mud flaps wheel arch and body mounted with transportation tie backs

- oilcooled brakes enclosed

- operator and passenger grab hand rails

- product link where applicable

- retarder engine compression brake

- ropsfops cab with full instrumentation including

Instrument cluster display module

Indicator lamps: left turn, secondary steering, primary steering loss, front and center axle brake temp (735B/740B and 740B Ejector only), brake oil pressure, action lamp, transmission fault, park brake, charging system status, differential lock fault, body not in float, right turn, high beam, transmission hold, machine filter warning, retarder, retarder up shift warning

Gauges: engine oil pressure, engine coolant temperature, torque converter oil temperature, fuel level, fuel tank level gauge

LCD warnings/indicators: Gear, Alert, Speed, Soot, DPF Regeneration, Engine hours, Primary Steer, 2nd Steer, Machine Security (MSS), Retarder

Meters: service hour meter, speedometer, tachometer - seat fully adjustable air suspension

- seat padded passenger

- secondary steering electronic

- s∙o∙ssm sampling valves

- spill guard front integral part of fabricated body

- starting receptacle electric remote

- storage two cup holders flask receptacle under seat storage door pocket behind seat storage coat hook

- sun visor

- threeaxle six wheel drive

- tilt and telescopic steering wheel

- tires 295r25 radial

- towing eyes front and rear tow pin

- two seat belts retractable

- vandalism protection lockable caps for fuel tank and hydraulic oil tank

- windows opening side tinted

- windshield wiper and washer two speed intermittent front

- windshield wiper and washer two speed rear

740B Bare Chassis OPTIONS

- autolube installation for automatic greasing of bearings

- body liners

- cdradio heavy duty with auxiliary input

- cold weather coolant 51° c598° f

- cold weather start attachment

- engine block heater

- exhaust heated body

- fast fuel fill

- flashing led beacon

- fuel additive antiwaxing

- heated rearview motorized mirrors

- heated seats

- product link pl 321 pl 522 and pl 523 where available

- roof mounted work lights

- long wheel base rear chassis oem

- machine security system mss

- tailgate

Scissor-type

MOTEUR

Innovative technologies optimize performance.

BENEFITS AND FEATURES

ACERT Technology The Cat® C15 ACERT™ engine continues the evolutionary, incremental improvements that provide breakthrough engine technology built on systems and components developed by Caterpillar with proven reliability.

Cat Clean Emissions Module (CEM) CEM is an exhaust aftertreatment package consisting of a diesel particulate filter, and control systems. The CEM reduces particulate emissions using passive and active regeneration during normal engine operation.

Cat NOx Reduction System (NRS) The Cat NOx Reduction System (NRS) captures and cools a small quantity of exhaust gas, then routes it into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

Fuel Delivery Mechanically actuated Electronic Unit Injection (MEUI-C) multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures, generating fewer emissions and optimizing fuel combustion. This translates into more work output for your fuel cost.

Diesel Particulate Filter Regeneration

Proven Reliability.

BENEFITS AND FEATURES

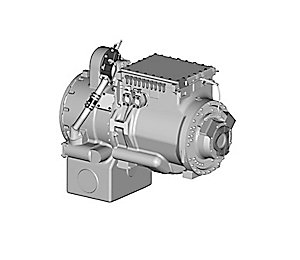

Electronic Transmission The Cat seven-speed forward two-speed reverse Electronic Clutch Pressure Controlled (ECPC) transmission features enhanced shift control logic with anti-hunt shift strategy for speed continuity, and to ensure constant shift times.

Min-max Governor Control ECPC control is matched to the min-max governor control for precise smooth shifting.

Two Reverse Gears The transmission arrangement provides a second reverse gear for improved performance when operating in longer rear hauling applications.

Smooth Transmission Gear Shifting The 740B features ECPC Shift Torque Management (STM), with improved Shift Control Logic (SCL) and Part Throttle Shifting (PTS). These features allow smoother shifting and greater acceleration on grades while torque is maintained through the shift changes. SCL also provides automatic shift selection that is more specific to the desired machine operation, and downshifts when needed for maximum acceleration when increased throttle is applied. PTS allows shifting at lower speeds during part throttle operation, resulting in improved part throttle fuel economy, quieter machine operation, and better maneuvering in reduced speed operating conditions.

Performance and Productivity.

BENEFITS AND FEATURES

Front Suspension The three-point front suspension oscillates ±6° to provide a smooth ride, allowing the operator to travel at speed over rough terrain and softening impact loads on structures and components. Large bore, low pressure cylinders are purpose designed for tough applications and offer a soft, smooth ride.

Rear Suspension Features a walking beam geometry with Caterpillar designed rear suspension mounts which provide a reliable and stable ride for excellent load retention.

Automatic Traction Control Fully Automatic Traction Control (ATC). Inter-Axle-Differential lock (IAD) and Cross-Axle-Differential locks (XAD) feature oil immersed clutches that require no operator input. Operation is seamless and smooth, and it eliminates wheel slip for maximum traction. Sensors monitor the machine and wheel speeds, enabling instant response in low traction conditions. Fully automatic, independent, IAD and XAD clutches are engaged on-the-go to optimize machine performance and control in all conditions. Clutches are automatically disengaged when ground conditions dictate, maximizing efficiency when steering or on uneven ground. ATC eliminates wheel spin in soft under foot extreme ground conditions where little traction is available. It also reduces tire and driveline abuse eliminating lost efficiency caused by improper manual operation of the differential clutches.

Retardation Control The Cat engine compression brake control lever is positioned on the right-hand side of the steer column. Four modes of operation with three steps of retardation, provide an optimum match between operating conditions and retarding power.

High productivity from a comfortable, confident operator.

BENEFITS AND FEATURES

Ride Comfort The three-point front suspension with its oscillating axle and low-pressure ride struts, combined with the center-mounted cab, offers unrivaled levels of ride comfort for the operator in all driving conditions. The operator remains comfortable and productive throughout the day.

Spacious Two-Person Cab The 740B features a large two-person cab, offering comfortable working space for both the operator and passenger. The 735B, 740B and 740B ej articulated trucks use the same spacious cab design.

Air Suspension Seat The air suspension seat enhances operator comfort with a cushioned upper high back, adjustable damping with three settings, ride zone indicator and adjustable lumbar settings. It is fully adjustable to provide the optimal driving position.

Passenger Seat Full-size passenger seat features a fully padded seat with a backrest and a wide, retractable seatbelt for a secure and comfortable ride. The passenger seat is positioned next to the operator seat, giving both the operator and passenger a clear view of the instrument panel, controls and the road.

Steering Column A comfortable driving position is provided by a telescopic and tilt adjustable steering column.

Designed for ease of use - allows the operator to focus on production.

BENEFITS AND FEATURES

Ergonomic Layout The controls and layout of the cab are designed to make it as easy to operate as your car. Quick, easy to read and simple to operate, the controls and gauges on the 740B allow the operator to concentrate on production.

Dash The integrated wrap-around dash puts all controls within easy reach of the operator. Featuring LED illuminated rocker switches for the dash dimmer, rear wash wiper, hazard warning, head lamp, work lamp, heated mirrors (optional), diff-lock, secondary steer, heated seat (optional), machine security system (optional), A/C and cigar lighter. Color Multi-Purpose Display (CMPD) unit incorporating the messenger and rearview display. Provides an automotive feel with the industrial strength you would expect from Caterpillar.

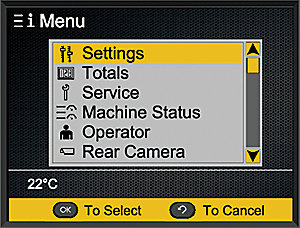

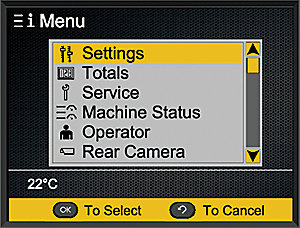

Color Multi Purpose Display (CMPD) A multi screen display unit showing various levels of machine warning categories, performance and condition pages, including: Performance, Settings, Totals, Service, Machine Status, Operator, and Rearview Camera.

Warning Categories The monitoring system provides four warning categories. The first warning category requires only operator awareness. The second warning category requires a change in machine operation or maintenance to the system. The third warning category requires an immediate change of the machine operation. The fourth category requires the operator to immediately stop the machine. The fourth category also requires the operator to immediately shut down the engine.

Viewing Area The low sloping hood and placement of the cooling package behind the cab give the operator excellent all-around visibility. The large glass area and central operator position also provide excellent visibility.

Transmission and Hoist Levers The hoist lever provides easy, comfortable operation. The transmission lever offers excellent comfort, and control for top gear limit, transmission hold and neutral lock.

High machine availability maximizes productivity and lowers costs.

BENEFITS AND FEATURES

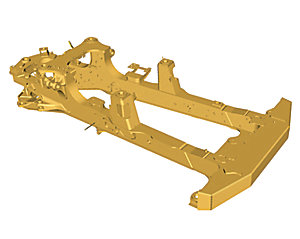

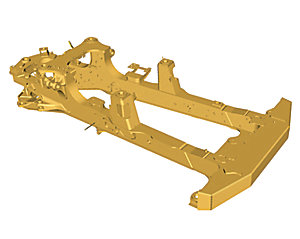

Front Frame The front frame design features a large box section and wide, stiff frame beams to handle torque loads. The divergent frame design decreases stress in the hitch area and optimizes suspension geometry. The frame design makes maximum use of robotic welding for increased durability.

Rear Frame Twin-box construction minimizes stress concentrations and provides low weight with long service life.

Suspension The three-point oscillating axle front suspension provides unparalleled ride quality. It also protects the truck from adverse road conditions by absorbing shock loads that would reach the frame.

Articulating/Oscillating Hitch The articulating hitch provides the truck with steering articulation, and the oscillation ensures all-wheel ground contact in rough terrain.

Hitch Construction Two-piece construction features a durable cast steel head bolted to a hard-wearing forged steel tube.

Fast Hoist Cycle Times Fast body raise and lower times mean less time spent in the dump area.

Load-Carrying Capacity The 740B has a large target area to provide consistently high load-carrying capacity. Its diverging flow design gives clean load ejection, which maximizes production and avoids the waste of material carry-back.

Output Transfer Gear Provides lubrication of all bearings and clutches using a distributed-pressure lubricated and filtered system.

Enclosed, Oil-Cooled Brakes High performance multi-plate, oil-immersed brakes are only required on front and center axles. These brakes provide outstanding stopping capability, while maintaining maximum durability and low wear characteristics.

Parking Brake Fitted to the center axle in an elevated position, spring applied and hydraulically released.

A secure and user-friendly application.

BENEFITS AND FEATURES

Cat Product Link* Cat Product Link allows remote monitoring of the Articulated Truck to improve overall fleet-management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink™. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working/idle time, fuel level and more. * Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

Key Points

- See your entire fleet at a glance

- Monitor fuel usage

- Set up site boundaries and security alerts

- Click through to your Cat dealer for service and parts

- Customize the alerts and displays that matter to you

- Compare working time versus idle time

- Reduce owning and operating costs

- Get the right information to the right people at the right time

- Vital Information Maintenance System (VIMS™) upgrades available

New Features

- Completely updated

- Robust new hardware

- Remarkably intuitive web-based interface

- Satellite and cellular coverage

- Open-system design for mixed-fleet use

More time on production.

BENEFITS AND FEATURES

Long Service Intervals Long engine oil change and hydraulic oil change intervals reduce maintenance costs and downtime. Wheel-bearing adjustment is completely eliminated.

Lubrication Points Lubrication points are grouped at the rear of the front frame and the front of the rear frame. Universal joints are lubricated for life, eliminating servicing. Autolube is optional.

Service Points Engine and transmission dipstick and fill caps, air and fuel filters, and the fuel priming pump are all mounted on the left side of the engine under the electrically raised hood. Coolant level indicator and fill cap are outside the cab.

Radiator The radiator package is located behind the cab, which provides protection from frontal impacts and offers easy access to the inlet and outlet sides of the radiator. The Air To Air After Cooler (ATAAC) radiator is located at the front of the truck.

Extended Life Coolant Extends the change interval and improves component life by reducing aluminum corrosion.

Electrical Service Center Located inside the cab, this service center provides a power port, diagnostic connector and Cat Data Link connector.

Cat Data Link Connector The Cat Data Link connector provides a plug-in using a laptop computer with Electronic Technician (ET) software.

Service Access The cab tilts to the side to provide easy access underneath, which simplifies access to the transmission, drive shafts and hydraulic pumps. Machine electrical and hydraulic interfaces are located on the right side of the cab, behind a removable cab body panel for easy access.

Truck Transport The suspension system eliminates the need to lower the suspension when transporting the truck, reducing maintenance and downtime.

Cat® dealer services help you operate longer with lower costs.

BENEFITS AND FEATURES

Selection Make comparisons of the machines you are considering before you buy. Your Cat® dealer can help.

Purchase Consider the resale value, compare productivity and day-to-day operating costs and fuel consumption.

Operation For the best operating techniques to increase productivity and your profit, turn to your Cat dealer for the latest training literature and trained staff.

Maintenance Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Technical Analysis help you avoid unscheduled repairs.

Replacement Repair or rebuild? Your Cat dealer can help you evaluate the costs so you can make the right choice.

Product Support Your local Cat dealership will be with you every step of the way with its unsurpassed worldwide parts support, trained technicians and customer support agreements.

cat.com For more complete information on Cat products, dealer services and industry solutions, visit us on the Web at www.cat.com

Designed with safety as the first priority.

BENEFITS AND FEATURES

Product Safety Caterpillar has been and continues to be proactive in developing machines that meet or exceed safety standards. Safety is an integral part of all machines and system designs.

Safety Features

- Cab integral ROPS (Roll Over Protection System) and FOPS (Falling Object Protection System)

- Rearview camera system provides a continuous panoramic rear view or when reverse gear is selected

- The secondary and parking brake functions are spring applied and hydraulically released

- Electro-hydraulic secondary steering system, automatically activates in forward/reverse or when stationary if low pressure is sensed. Can be manually selected for machine recovery purposes.

- External engine fuel cut off switch for easy access from outside of the machine

- External electrical system disconnect switch for easy access from outside of the machine

- Slip resistant surfaces - punched steel plate

- Hood raise and lower switch fitted at the LHS of dash

- 75 mm (3 in) wide retractable seat belts for operator and passenger/trainee

- Cab roof mounted work lights

- Wide angled mirrors for excellent rear visibility

- Sweeping hood design for panoramic forward visibility

- Extensive hand rails

- Body raised alarm

- Heated motorized mirrors (optional)

- LED flashing beacon

Resourceful in every way.

BENEFITS AND FEATURES

The 740B is designed to maximize efficiency and productivity while conserving natural resources.

Air Quality The C15 ACERT engine incorporating the Cat Clean Emission Module (CEM) meets EPA Tier 4 Interim/Stage IIIB emissions requirements and is designed to incorporate Tier 4 Final/EU Stage IV emissions systems at future machine product introduction. The C15 ACERT engine has the flexibility of running on either ultra-low-sulphur diesel (ULSD) fuel or bio-diesel blended with ULSD. All fuels must have no more than 15 ppm sulfur.

Re-cycle Waste The Caterpillar Design, Manufacturing, Assembly and Test Site at Peterlee in England re-cycle 90% of all waste produced. The 740B is manufactured to be rebuilt and remanufactured to reduce waste and replacement costs. The 740B is an efficient, productive machine that is designed to conserve our natural resources for generations ahead.